Case: Ceiling T Grid Roll Forming Machine

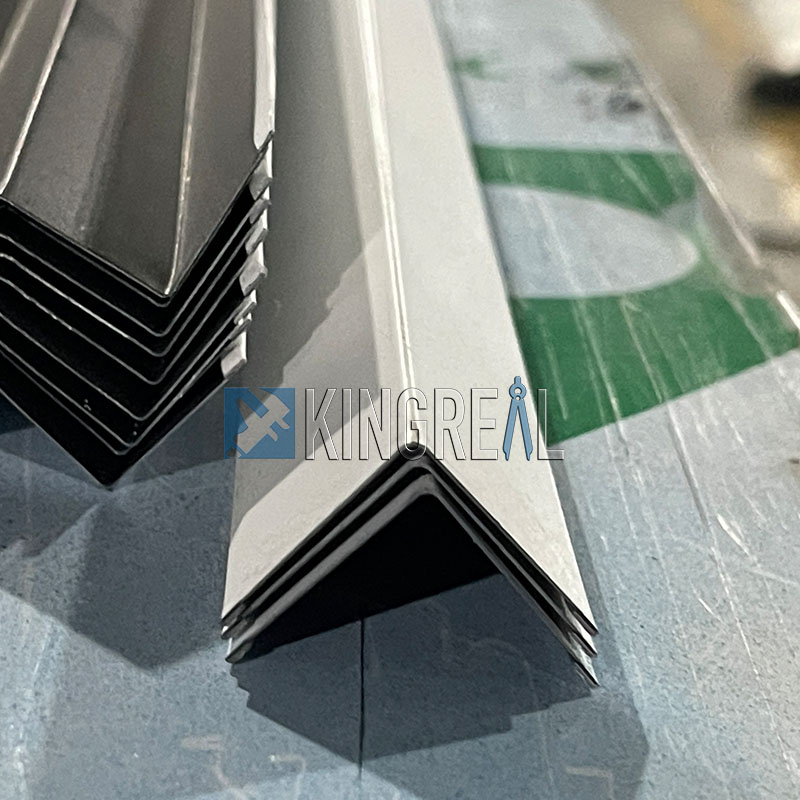

2025-04-10 12:00Ceiling T Grid Roll Forming Machine is an indispensable equipment in modern ceiling system. It is mainly used to produce ceiling t bar of different types and sizes and is widely used in the construction and decoration industry. KINGREAL Ceiling T Grid Roll Forming Machine can meet the diverse needs of customers with its excellent performance and flexible design. KINGREAL Ceiling System T Grid Rolling Machine can produce ceiling t grid of various specifications, including: main t, cross t and wall angle.

KINGREAL Ceiling T Grid Roll Forming Machine has successful cooperation cases in many countries and regions, including Saudi Arabia, Brazil, Vietnam, Bangladesh and India. On the occasion of the upcoming 137th Canton Fair, KINGREAL is very honored to introduce you to some successful cases of cooperation with customers. If you are interested in our Ceiling System T Grid Rolling Machines, welcome to visit the factory in person.

Case 1: Providing Production Safety for Indonesian Customers

Customer background

The Indonesian customer is a company specializing in the production of building materials. When choosing Ceiling T Grid Roll Forming Machine, they pay special attention to the safety of factory workers. The Ceiling System T Grid Rolling Machines used before lacked sufficient safety protection measures, which increased safety hazards, caused workers to feel uneasy during operation, and affected work efficiency and employee morale. The Indonesian customer hopes to purchase a Ceiling T Grid Roll Forming Machine that can meet production needs and ensure the safety of workers.

Solution

After a deep understanding of the Indonesian customer's needs, KINGREAL engineers proposed a design for a Ceiling T Grid Roll Forming Machine with a protective shield. The design of the protective shield can not only effectively isolate the moving parts of the Ceiling System T Grid Rolling Machine and prevent workers from accidental injuries during operation, but also ensure the normal operation of the Ceiling T Grid Roll Forming Machine. The protective shield is made of transparent material, allowing workers to clearly observe the working status of the Ceiling System T Grid Rolling Machine and monitor the production process at any time.

During the design process, KINGREAL also ensured that the protective shield would not affect the production speed and quality of the Ceiling T Grid Roll Forming Machine. By optimizing the layout and construction of the Ceiling T Grid Roll Forming Machine, the engineers successfully achieved a balance between production safety and efficiency. In the end, the Indonesian customer was very satisfied with this solution and decided to purchase this new Ceiling System T Grid Rolling Machine.

Feedback

After the new Ceiling T Grid Roll Forming Machine was put into use, the Indonesian customer's factory safety was significantly improved. The workers felt more at ease when operating the Ceiling T Grid Roll Forming Machine, and their work efficiency was also improved. By introducing this safety design, the Indonesian customer not only improved the safety standards of the factory, but also enhanced the work enthusiasm of employees, and finally achieved a significant increase in production efficiency. Indonesian customer feedback stated that since the introduction of the new Ceiling System T Grid Rolling Machine, the accident rate in the factory has dropped by more than 50%, and the workers' satisfaction has also been significantly improved.

Case 2: Solving Production Needs of Russian Customers for Ceiling T Grid of Different Sizes

Customer background

The Russian customer is a mature ceiling t bar seller with a wide market network and a stable customer base. They are faced with the production needs of ceiling t grid of different specifications, and the traditional production model cannot meet the market demand for diversified products. The Russian customer hopes to find a machine that can flexibly produce ceiling system t grid of various sizes in order to quickly respond to market changes.

Solution

KINGREAL engineering team designed a flexible Ceiling System T Grid Rolling Machine based on Russian customer needs. The Ceiling T Grid Roll Forming Machine can produce ceiling t grid of various specifications on one production line. By replacing the roller set and the cutting die, the Russian customer easily achieved the production of 38x24mm and 38x25mm ceiling t bar.

In addition, the control system of the Ceiling System T Grid Rolling Machine has also been optimized, and customers can quickly adjust the production specifications through simple parameter settings. This flexibility makes the Ceiling T Grid Roll Forming Machine an ideal choice for Russian customers' mass customization production, which can meet customers' needs for diversified products in a short time.

Feedback

The Russian customer successfully achieved a rapid response to market demand and improved market competitiveness. By introducing KINGREAL Ceiling System T Grid Rolling Machine, the Russian customer's production efficiency has increased by more than 40% and production costs have been significantly reduced. The Russian customer said that since using the new Ceiling T Grid Roll Forming Machine, the order delivery time has been shortened, which has greatly enhanced customer satisfaction and trust. They have also gained more new customers and their business volume has increased significantly.

Case 3: Providing Fully Automatic Ceiling T Grid Production for Vietnamese Customers

Customer background

The Vietnamese customer is a fast-growing building materials manufacturer facing an expanding production scale and growing market demand. They hope to introduce a Ceiling T Grid Roll Forming Machine that can achieve fully automated and high-speed production to improve production efficiency and reduce labor costs. The Vietnamese customer hopes to reduce manpower input and improve production stability and consistency through automation technology.

Solution

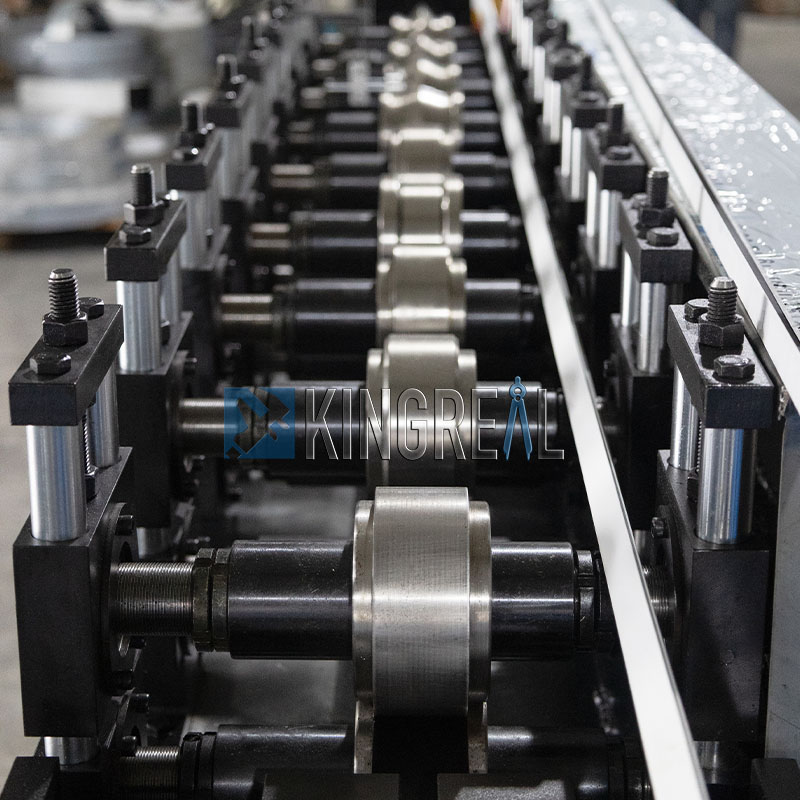

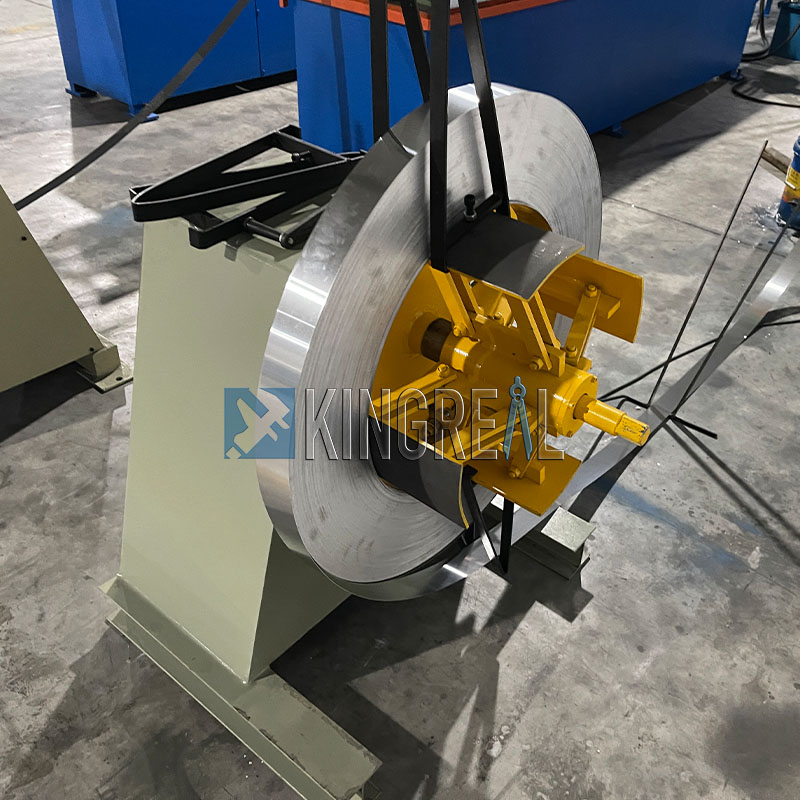

KINGREAL designed a fully automatic Ceiling System T Grid Rolling Machine for the customer based on its needs. The Ceiling T Grid Roll Forming Machine consists of precision components such as hydraulic decoiler, main roll forming machine, punching and shearing station, and product table. The Vietnamese customer only needs to enter the parameters on the control panel, and the Ceiling System T Grid Rolling Machine will run automatically, with a maximum production speed of 30m/min.

This fully automated Ceiling T Grid Roll Forming Machine uses an advanced control system that can monitor various data in the production process in real time to ensure the accuracy and stability of production. Through the continuous rolling process, the metal strip is gradually bent into the required vertical profiles. The whole process does not require human intervention, which greatly improves production efficiency.

Feedback

The commissioning of the new Ceiling T Grid Roll Forming Machine has enabled the Vietnamese customer to achieve a qualitative leap in production efficiency. Compared with traditional manual operation, the introduction of the automated Ceiling System T Grid Rolling Machine has increased production efficiency by more than 60%. At the same time, the quality of the finished product is also guaranteed. Due to the reduction of human interference, the consistency and qualified rate of the product are significantly improved. The Vietnamese customer is very satisfied with KINGREAL fully automated solution, believing that it not only improves production capacity, but also saves the company a lot of labor costs.

Case 4: Providing a Complete Solution for Suspended Ceilings for Saudi Arabian Customers

Customer Background

Saudi Arabian customers are faced with the challenge of providing suspended ceiling installation services to customers in the suspended ceiling industry. They hope to find a complete solution to provide customers with an integrated suspended ceiling system.

Solution

KINGREAL engineers discussed several ceiling solutions with Saudi Arabian customers in depth and proposed the following combinations:

1. The main t and cross t produced by the Ceiling T Grid Roll Forming Machine are assembled into a complete ceiling solution.

2. The main t , cross t and wall angle produced by the Ceiling System T Grid Rolling Machine are combined into a complete ceiling solution.

3. The main t , cross t produced by the Ceiling System T Grid Rolling Machine are assembled with the LAY IN ceiling to form a complete ceiling system.

After detailed discussions, the Saudi Arabian customer considered that the combination of the main t, cross t with the LAY IN ceiling was the most suitable solution based on its actual situation, so it decided to purchase the Ceiling T Grid Roll Forming Machine and the LAY IN ceiling production line. KINGREAL provided comprehensive technical support to ensure that the customer could proceed smoothly during the production process.

Feedback

This complete solution not only improved the Saudi Arabian customer's production capacity, but also enhanced its market competitiveness. The customer was able to provide the market with a variety of ceiling products in a short period of time to meet the needs of different customers. Since the introduction of KINGREAL solution, the Saudi Arabian customer's market share has increased significantly and the order volume has doubled. The customer highly praised KINGREAL professional services and technical support and expressed that it will continue to maintain a long-term cooperative relationship with KINGREAL.

Case 5: Providing One-stop Service for Bangladeshi Customers

Customer background

Bangladesh customers want to enter the ceiling t grid manufacturing industry, but they only collected some basic information on the Internet and the market, and did not know enough about the specific operation and production process of the Ceiling T Grid Roll Forming Machine. They hope to get comprehensive technical support and training to start the business smoothly.

Solution

KINGREAL warmly received the Bangladeshi customers, invited them to visit the factory and introduced the Ceiling System T Grid Rolling Machine and finished product information in detail. After the Bangladeshi customer personally tested the Ceiling System T Grid Rolling Machine, the two sides discussed the customized solution of the Ceiling T Grid Roll Forming Machine in depth in the conference room.

KINGREAL not only provides Ceiling System T Grid Rolling Machine manufacturing, but also provides customers with one-stop service from equipment installation to operation training. After the machine was manufactured, KINGREAL engineers went to the Bangladeshi customer's factory to install the Ceiling T Grid Roll Forming Machine and taught the workers daily maintenance knowledge to ensure that the customer can operate the Ceiling T Grid Roll Forming Machine independently and efficiently.

Feedback

The Bangladeshi customer was very satisfied with the one-stop service provided by KINGREAL and put it into production with peace of mind. Through comprehensive training and technical support, the customer's workers quickly mastered the operation skills of the Ceiling System T Grid Rolling Machine, production started smoothly, and the business soon became profitable. Bangladeshi customers said that KINGREAL support made them feel extremely relieved when entering new markets and also strengthened their confidence. They plan to expand production in the future and continue to cooperate with KINGREAL.