After-sales Service : Metal Ceiling Machine in Italy

2025-04-18 12:00In January this year, KINGREAL engineers traveled to Italy to the customer's factory to provide offline installation services for the newly arrived metal ceiling machine. This mission is not only a test of KINGREAL technical strength, but also an important step in establishing a long-term cooperative relationship with customers. KINGREAL engineers fully utilized their professional skills and worked hand in hand with Italian workers to ensure the smooth installation and commissioning of the aluminum ceiling tile production line.

Preparation for the Trip to Italy

Before departure, KINGREAL engineers made detailed preparations. Not only did they review the design and functions of the metal ceiling machine, but they also sorted out the tools and equipment required for installation. In order to ensure the smooth progress of the service, KINGREAL engineers also communicated with Italian customers in advance to understand the customer's specific needs and factory environment, so that they could quickly respond to various situations during the installation of the aluminum ceiling tile production line.

Main Components of the Aluminum Ceiling Tile Production Line

The composition of the metal ceiling machine includes several key components. KINGREAL engineers worked together with Italian workers to quickly complete the assembly of the following main components:

- Hydraulic Decoiler: used to unfold the coil for subsequent processing.

- Precision Straightener: Ensures the flatness of the material and provides a stable foundation for processing.

- Perforation Press: Used to punch holes in metal plates for subsequent processing and assembly.

- Servo Feeding Machine: Precisely controls the feeding of materials to ensure the continuity and efficiency of production.

- Notching and Shearing Press: Used to cut and notch the material to meet design requirements.

- 2nd Precision Straightener: Further ensures the flatness of the material and improves the quality of the finished product.

- Tiles Flipping Machine: Used to flip the ceiling for subsequent processing and patching.

- Automatic Tiles Feeding Machine: Automates material feeding to improve production efficiency.

- Auto Bending Forming Press: Used to bend the material to meet design requirements.

The efficient cooperation of these components constitutes a complete aluminum ceiling tile production line that can meet the dual requirements of Italian customers for production efficiency and quality.

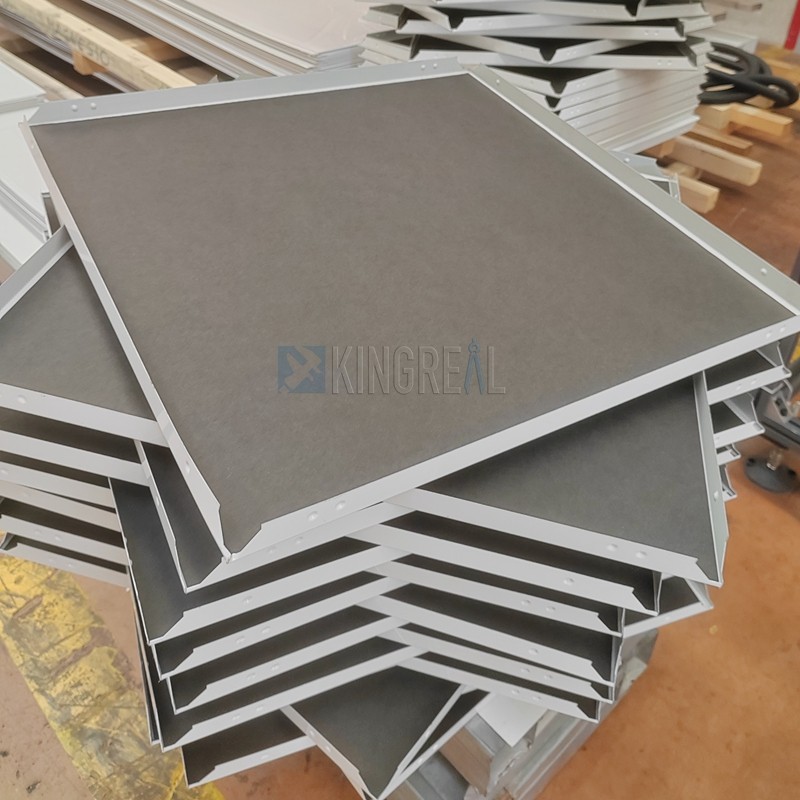

Special Configuration of Acoustic Fleece Sticking Machine

What makes this metal ceiling machine unique is that KINGREAL has specially equipped a acoustic fleece sticking machine according to the special needs of Italian customers. Italian customers want to produce sound-absorbing ceilings, so KINGREAL engineers designed a process for patching after the metal ceiling is produced. This design not only enables one metal ceiling machine to complete the manufacture of sound-absorbing ceilings, but also greatly reduces the trouble of subsequent secondary processing for Italian customers.

During the installation process, the engineer explained the operation process of the patch machine in detail to ensure that Italian workers can master this key process and further improve production efficiency.

Meticulous Work During the Installation Process

During the installation of the aluminum ceiling tile production line, KINGREAL engineers showed extremely high professionalism and careful attitude. Through multiple metal ceiling machine tests, the parameters of each component were fine-tuned to ensure that the aluminum ceiling tile production line can perfectly meet the production needs of Italian customers. KINGREAL engineers carefully recorded every adjustment and test to ensure that every detail can achieve the best results.

Demonstration and training

After the installation, KINGREAL engineers first demonstrated to Italian customers how to use the aluminum ceiling tile production line. Through actual operation, Italian customers were able to intuitively understand the functions and operating points of each component. Subsequently, KINGREAL engineers conducted systematic operation training for the workers to ensure that they could operate the metal ceiling machine independently.

During the training, KINGREAL engineers were conscientious and responsible, carefully observed the operation of the Italian workers, recorded problems in a timely manner and provided guidance. Through this interactive training, the workers not only mastered the basic operation of the aluminum ceiling tile production line, but also learned how to deal with common problems, improving the safety and efficiency of production.

Frequently asked questions

At the end of the training, KINGREAL engineers sorted out the common problems encountered by Italian workers in operation and corrected them one by one. This patient and meticulous service has been highly recognized by customers and has enhanced their confidence in KINGREAL after-sales service.

Daily maintenance guidance

In addition to operation training, KINGREAL engineers also emphasized the importance of daily maintenance of the metal ceiling machine. They explained in detail to Italian customers how to perform daily maintenance, including regular cleaning, lubrication and inspection. In order to facilitate the subsequent operation of Italian customers, KINGREAL engineers also handed over detailed user guides and manuals to Italian customers to ensure that customers can quickly refer to them in daily use.

Customer Feedback and Satisfaction

After a series of installation, commissioning and training, KINGREAL engineers successfully completed the installation task of the metal ceiling machine. Italian customers are very satisfied with the professional services of engineers and believe that KINGREAL not only provides high-quality aluminum ceiling tile production lines, but also provides a full range of after-sales services.

Italian customers mentioned in their feedback that KINGREAL engineers' meticulousness and high professionalism made them feel deeply trusted, which laid a solid foundation for future cooperation. Italian customers said that they look forward to continuing to cooperate with KINGREAL in future projects to jointly promote the development of business.