Customer Visit - Metal Perforating Machine

2024-11-26 17:36Recently, after many days of communication with the KINGREAL technical specialist network to understand the machine situation, a Bangladeshi customer who has strong interest in the sheet metal perforation machine line accepted the invitation of KINGREAL and came to the factory for a field visit. The main purpose of the visit was to check the operation of the metal perforating machine and whether the quality of the finished product meets the requirements of the Bangladeshi customers.

First of all, KINGREAL staff warmly welcomed the Bangladeshi customer and transferred the customer from Guangzhou Airport to the Foshan factory.

During the factory inspection, KINGREAL staff introduced to the customer that the whole sheet perforation machine production line is composed of main components such as decoiler, precision leveler, sheet perforation machine, cutting station, etc. The finished product is made of metal sheet material through the process of unwinding, flattening, punching, cutting and so on.

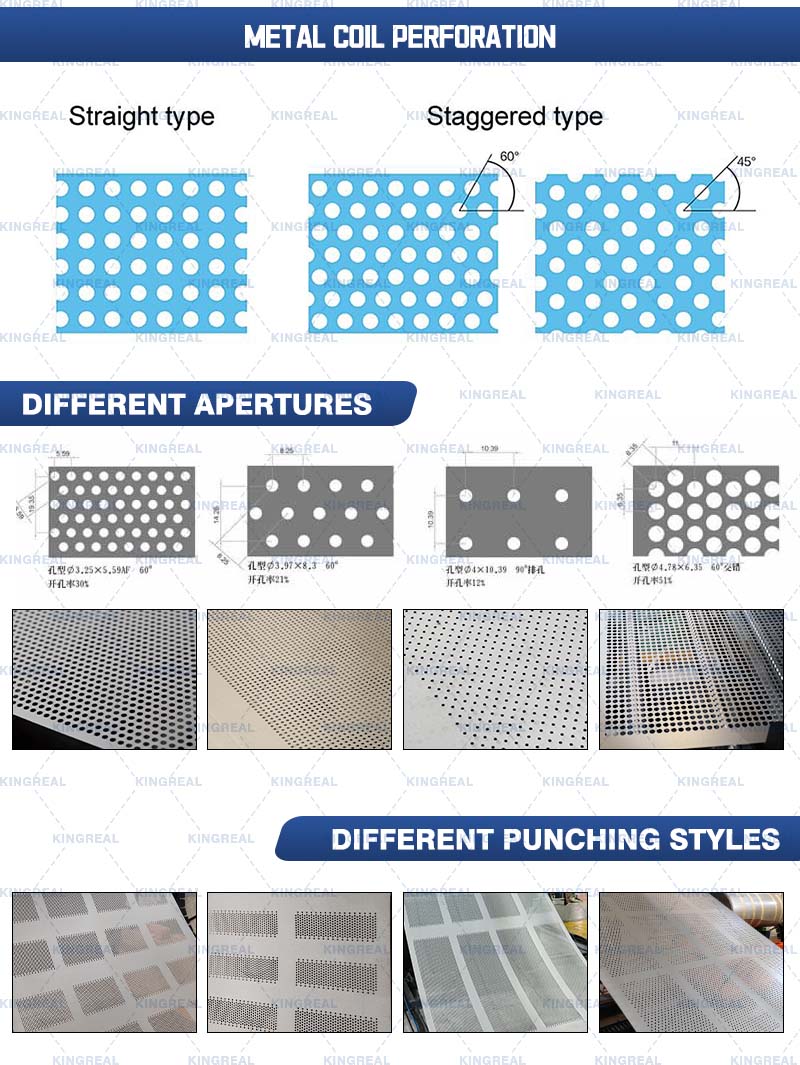

During the visit to the automatic metal perforating machine, the customer also asked many questions, such as how to achieve the production of different pass shapes through a single sheet metal perforation production line. In this regard, the engineer explained in detail that the production of different styles of finished products is mainly accomplished by moving the pin. In order to make the Bangladeshi customer more intuitive understanding, KINGREAL engineers not only explained each step of the operation in detail orally, but also operated the equipment personally, showing the customer the whole process of how to move the pin. The whole operation is very convenient, saving time and the cost of buying other machines.

The customer in Bangladesh recognized the sheet metal perforation production line of KINGREAL very much, and reached an initial cooperation intention with KINGREAL.

KINGREAL automatic sheet perforation production line has the following main features:

① The leveling machine has more rollers, and the coil is more flat. This leveling machine has a total of 9 rollers, of which the upper roller has 4, the lower roller has 5. The number of rollers of the leveling machine can make the metal sheet more flat and improve the punching accuracy.

② Decoiler with trolley. The decoiler in the KINGREAL sheet metal perforation production line is equipped with a feeding trolley, which does not require manual loading, saving labor and time costs. Automated production lines greatly improve production efficiency.

③ High-speed punching. KINGREAL metal perforating machine punching speed can reach 100-180spm, punching speed is fast, to ensure your production speed.

The KINGREAL automatic metal perforating machine is one of our most distinctive products and one of the most purchased lines from manufacturers. As a professional punching production line manufacturer in China, KINGREAL has more than 20 years of experience from design - production - installation - after-sales, and can customize production solutions according to customers' drawings and specific parameter requirements.

Customer satisfaction is the biggest support for KINGREAL, KINGREAL will continue to work hard in the punching production line industry. If you also have a need for metal perforating machines, you are welcome to contact us.