- Home

- >

- News

- >

- Goodbye 2024, Hi 2025!

- >

Goodbye 2024, Hi 2025!

2025-01-01 00:002024 is a year full of challenges and opportunities for each of us. For KINGREAL, this year is a year of close cooperation and common growth with customers. On such a special day today, all the staff of KINGREAL wish you a happy new year! All the best in 2025!

Thank you for choosing KINGREAL and thank you for your valuable feedback and suggestions in the past year. Every one of your comments is the driving force for KINGREAL to continuously improve and optimize. KINGREAL knows that only through close cooperation with you can KINGREAL continue to improve the quality of machines, optimize services and create greater value. This article will review the key work of KINGREAL.

What did KINGREAL do in 2024?

Looking back on 2024, KINGREAL has achieved a series of achievements and breakthroughs with the support of customers. Whether in machine sales, technical services, or customer satisfaction, KINGREAL has made significant progress. The following is a review of several key work of KINGREAL in the past year:

1

More than 50 machines were sent to customer factories

In 2024, KINGREAL reached friendly cooperation with customers from different countries, including Vietnam, India, Greece, Italy, Russia. The United Kingdom and other countries.

KINGREAL successfully sent more than 50 machines to customer factories, including KINGREAL's latest developed 300mm height baffle ceiling machine, stud and track machine with auto packing machine, roofing sheet machine with stacking machine, unistrut roll forming machine, etc.

Here are some KINGREAL cases to share with you:

(1) Open cell ceiling machine shipped to Vietnam

In January 2024, KINGREAL's open cell ceiling machine was confirmed as a qualified machine to be shipped to the Vietnamese customer factory after a rigorous test by KINGREAL staff.

KINGREAL open cell ceiling machine has the following features:

Compatible with two metal raw materials, aluminum and iron.

Only folded open cell ceilings can be produced, which is a good way to meet the needs of customers with a single type of open cell ceiling.

Equipped with a 16-ton punching station, the stroke reaches 100-150 times/minute.

(2) 300mm height baffle ceiling machine shipped to Italy

In July 2024, the 300mm height baffle ceiling machinewas shipped to the Italian customer factory.

KINGREAL 300mm height baffle ceiling machine has the following features:

Can produce baffle ceilings up to 300mm.

The roller of the roll forming machine is hollowed out, which effectively solves the problem of the roller of the roll forming machine being too heavy and the formed baffle ceiling being inaccurate.

Fast production speed, up to 30m/min.

Can produce baffle ceilings of different sizes. There is no need to frequently change the machine because of the production of baffle ceiling machines of different sizes. KINGREAL baffle ceiling machines can automatically adjust the width to produce baffle ceilings of different sizes.

Follow shearing. The shearing system uses follow shearing. You only need to enter the required cutting parameters, and the system can detect the length of the baffle ceiling material through the sensor and control the tool to cut at the right time.

(3) stud and track machine with inkjet sent to Greece

In November 2024, the stud and track machine with inkjet was sent to the Greek customer factory.

KINGREAL stud and track machine with inkjet has the following characteristics:

With inkjet. KINGREAL stud and track machine with inkjet function integrates this process into the production line, reducing manual operation and time costs. And it can do a good job of branding for customers' finished products.

Can produce studs and tracks of different widths. KINGREAL stud and track machine adopts advanced servo motor system, which can realize automatic adjustment to ensure that the width of the studs and tracks can be adjusted quickly and accurately during the production process. The entire roller width adjustment process takes only 10 minutes, which greatly saves customers' production time.

High-speed production. The maximum production speed of the KINGREAL stud and track machine can reach 100m/min, which greatly exceeds the production capacity of traditional equipment. High-speed production not only increases the output of the production line, but also helps customers reduce the production cycle, thereby reducing unit costs.

With auto packaging machine. The automatic packaging machine can automatically package the studs and tracks after production is completed, ensuring that the product packaging is standardized and neat, and reducing errors and inconsistencies in the manual packaging process.

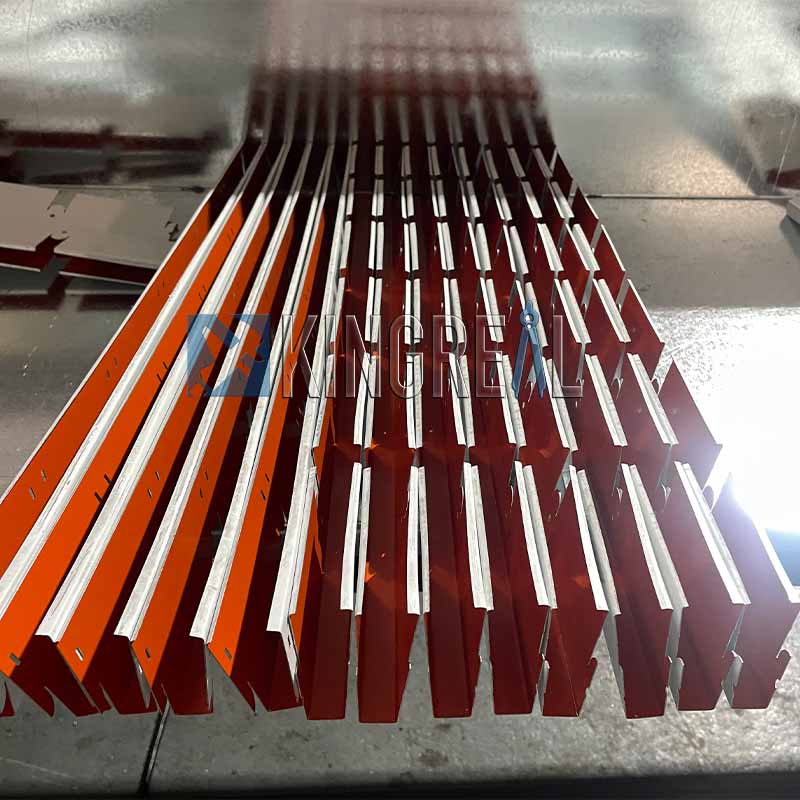

(4) Linear strip ceiling machine shipped to the UK

At the end of November 2024, the linear strip ceiling machine was shipped to the UK customer factory.

The KINGREAL linear strip ceiling machine has the following characteristics:

Different types of strip ceilings can be produced. It is easy to produce multiple types of strip ceilings with one machine by simply replacing the roller station, shearing station and mold. The operation is simple, reducing line change and adjustment time, and improving overall production efficiency.

Automatically adjust the width. Metal strip ceilings of different sizes can be produced in one machine. The size is controlled by a rotary encoder and can be set on the touch screen, allowing customers to flexibly choose the size of their products.

Strip ceilings with perforation can be produced. Just add a punching machine to the linear strip ceiling production line to produce strip ceilings with punching. There is no need to reorganize the production line on a large scale, reducing implementation costs and complexity.

These devices not only meet customers' needs for high efficiency and high precision, but also receive unanimous praise from customers. The sales growth not only proves the competitiveness of KINGREAL machines, but also demonstrates KINGREAL's efforts in marketing and customer service. KINGREAL will continue to invest more in product quality and innovation to ensure that it continues to maintain its market leadership in the future.

2

Reception of customer visits

In the past year, KINGREAL has received 100 customers from all over the world to visit and inspect KINGREAL's factory. Customers have gained a deep understanding of KINGREAL's production process and technical strength by personally visiting KINGREAL's production line and R&D center. KINGREAL provided customers with detailed technical explanations and equipment demonstrations to help them better understand KINGREAL's machines and further enhance customers' trust in the KINGREAL brand. These visits not only brought new business opportunities to KINGREAL, but also strengthened relationships with customers.

3

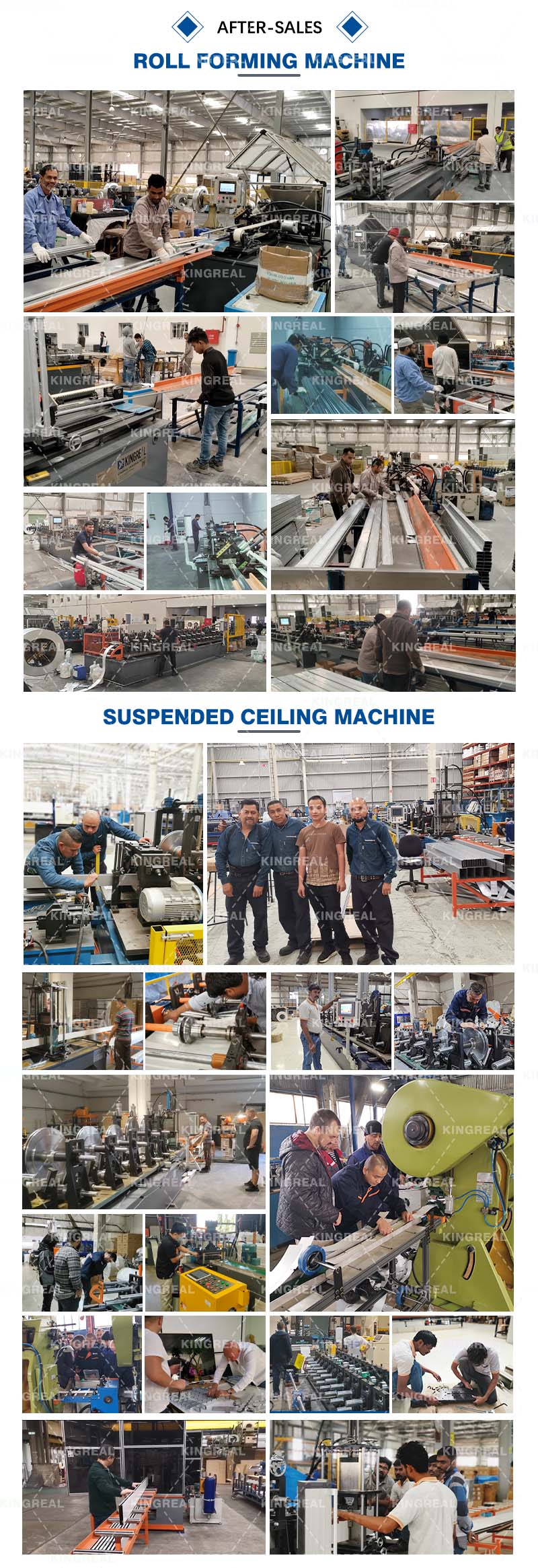

KINGREAL engineers went to customer factories to install machines offline

In the past year, KINGREAL's engineering team also traveled to many countries and regions to provide customers with on-site installation and commissioning services. When actually installing the machine, KINGREAL's engineering team always overcame multiple difficulties to ensure that the machine was smoothly installed in the customer's factory and put into production smoothly. Through on-site installation, KINGREAL not only helped customers solve practical problems, but also further improved customer satisfaction with KINGREAL's services. These on-site support services demonstrated the technical strength and service commitment of the KINGREAL team, and also won high praise from customers for KINGREAL.