How does a corrugated roof sheeting machine work?

2025-04-12 12:00The corrugated roof sheeting machine is a device that uses physical principles to process steel coil raw materials into metal tiles of different shapes. With the increasing demand for high-quality roofing materials in the construction industry, the corrugated metal roofing machine has gradually become an indispensable and important tool in modern construction. In this article, KINGREAL will give you a detailed introduction to the working principle, main components, advantages and importance of the corrugated roof sheet machine in the market.

1. Working Principle of Corrugated Metal Roofing Machine

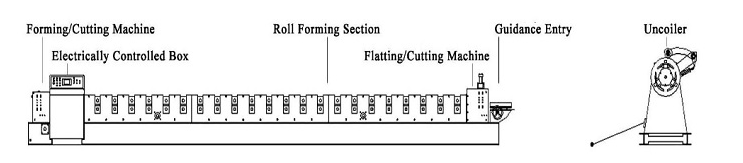

The working process of the corrugated roof sheeting machine is mainly divided into several key steps: raw material preparation, roll forming, automatic cutting and quality inspection. Through these steps, the corrugated roof sheet machine can efficiently and accurately produce corrugated roof panels that meet customer needs.

1.1 Raw material preparation

The first step in the manufacture of corrugated roof panels is to prepare the steel coil raw materials. The steel coil is usually surface-treated steel with good corrosion resistance and strength. During the production process, the steel coil will be placed on the decoiler, which unwinds the steel coil and feeds it into the roll forming machine.

1.2 Roll Forming

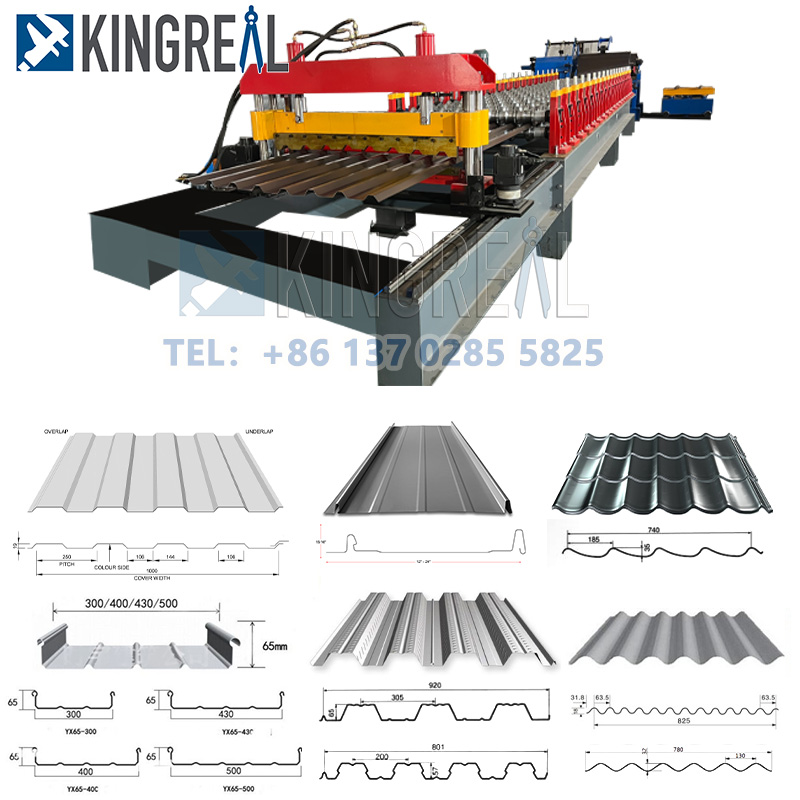

Roll forming is the core of the corrugated metal roofing machine. In this process, the steel coil is gradually pressed into the desired corrugated shape through a series of rollers. KINGREAL corrugated roof sheet machine uses high-precision roll forming technology and can automatically adjust according to the tile size and quantity entered by the customer.

1.2.1 Roller Design

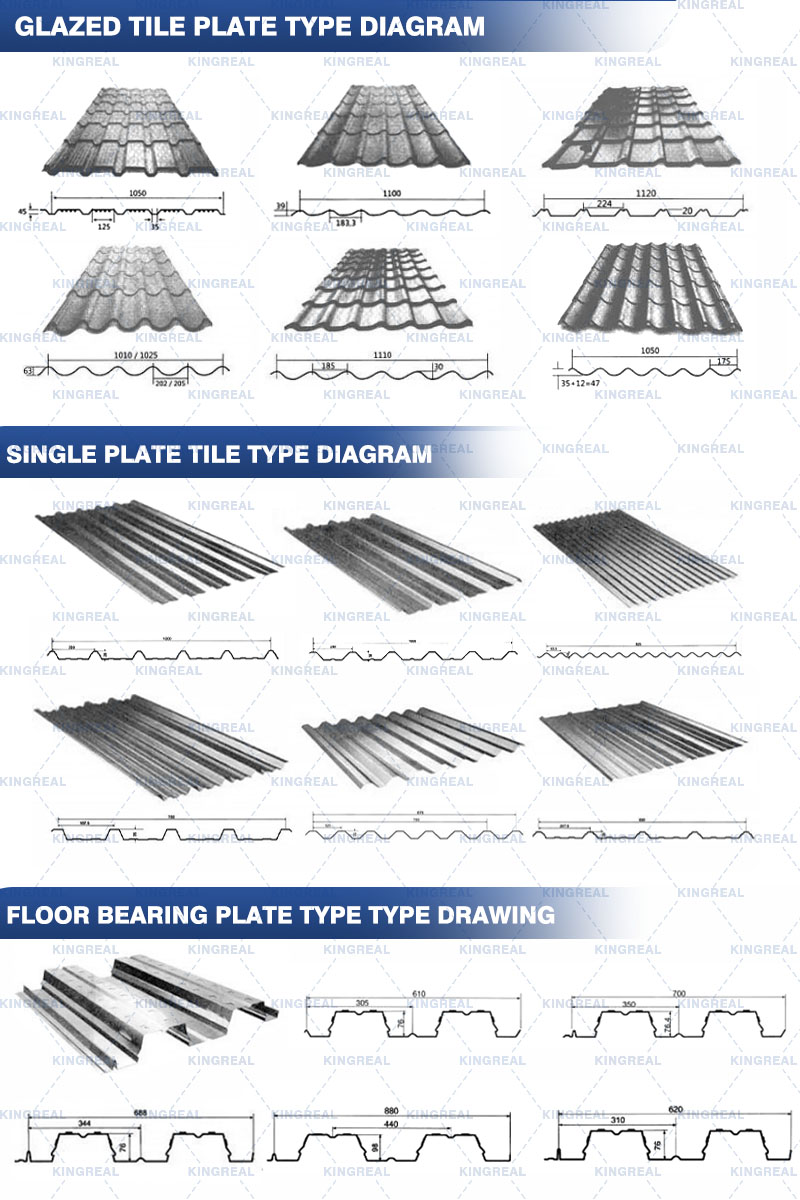

The design and arrangement of the rollers are crucial to the shape and quality of the final product. Each set of rollers is responsible for gradually shaping the steel to form a specific corrugated structure. By changing the arrangement and shape of the rollers, different types of corrugated roof panels can be produced to meet the diverse needs of the market.

1.2.2 Automatic Control System

The corrugated metal roofing machine is equipped with an advanced automatic control system. Users only need to enter the required tile size and quantity on the touch screen and click to start production. The system automatically adjusts the corrugated roof sheet machine’s working parameters to ensure that the expected corrugated roof panels are produced.

1.3 Automatic Cutting

After the roll forming is completed, the automatic cutting device of the corrugated metal roofing machine will accurately cut the finished product according to the set length. Precise control of this process ensures that each roof panel has consistent size, burr-free edges, and a smooth surface without scratches.

1.4 Quality Inspection

After production, the corrugated roof panels will undergo quality inspection to ensure that each product meets industry standards. KINGREAL equipment ensures high quality stability in this link, making the produced roof panels stand the test of time.

2. Advantages of Corrugated Roof Sheeting Machine

The design and manufacture of corrugated roof sheet machineshave multiple advantages, making them widely popular in the market.

2.1 Fast Production Speed

The fully automated operation of the corrugated metal roofing machine significantly increases the production speed. Compared with traditional manual production, the corrugated roof sheet machine's automated workflow greatly shortens the production cycle. KINGREAL corrugated roof sheeting machine can work efficiently at an extremely fast speed during the production process to meet the needs of large-scale production.

2.2 High Return on Investment

Enterprises that invest in corrugated metal roofing machines are usually able to achieve considerable returns in a short period of time. This is because automated production not only saves labor costs, but also improves production efficiency and reduces the defective rate caused by human errors. Through efficient production processes, enterprises can quickly respond to market demand and enhance competitiveness.

2.3 High precision and stability

KINGREAL corrugated roof sheet machine is precisely designed with high-quality materials and advanced technology, ensuring that the produced roof panels have millimeter-level accuracy. The high-precision cutting and forming process reduces waste in production and improves the overall quality of the product. At the same time, the stable production process makes the shape and size of each roof panel uniform and consistent, enhancing the market competitiveness of the product.

2.4 Strong adaptability

The design of the corrugated metal roofing machine can adapt to a variety of different roof panel shapes and sizes to meet the diverse needs of customers. Whether it is used for residential, commercial buildings or industrial facilities, the corrugated roof sheet machine can provide flexible solutions. This adaptability allows manufacturers to enter a wider market and increase business opportunities.

2.5 Quality Assurance

KINGREAL corrugated metal roofing machine strictly controls quality during the production process to ensure that each roof panel meets international standards. The equipment is CE and ISO certified to ensure the safety and reliability of the product. In addition, KINGREAL also provides 24/7 technical support and after-sales service to provide strong protection for customers' construction projects.

2.6 Energy saving and environmental protection

The modern corrugated roof sheeting machine fully considers the factors of energy saving and environmental protection when designing. Through efficient motors and optimized production processes, the corrugated metal roofing machine can effectively reduce energy consumption during operation. At the same time, the raw materials used have been surface treated and have good corrosion resistance and weather resistance, which prolongs the service life of the roof panels and reduces the impact on the environment.

3. Market Demand for Corrugated Roof Panels

With the continuous development of the global construction industry, the demand for corrugated roof panels is also growing continuously. Especially in South Africa, Zimbabwe and other African countries, corrugated roof panels are widely welcomed for their economy, durability and beauty. More and more construction projects choose to use corrugated roof panels as the main roofing material to meet the use needs under different climatic conditions.

3.1 Growth of the construction market

With the acceleration of urbanization, the demand in the construction market continues to increase. Corrugated roof panels have become the preferred material for builders because of their simple construction and convenient maintenance. Especially in low- and middle-income countries, corrugated roof panels are widely used because of their affordability.

3.2 Sustainable building materials

The use of corrugated roof panels is in line with the trend of sustainable construction. Its recyclability and long service life make corrugated roof panels an ideal choice for environmentally friendly building materials. More and more construction projects have begun to pay attention to the environmental performance of materials, and corrugated roof panels have therefore gained more market recognition.

As an important equipment for the production of modern building materials, the corrugated roof sheet machine occupies an important position in the market with its high efficiency, precision and flexibility. Through advanced technology and strict quality control, the corrugated metal roofing machine can meet customers' diverse needs for roof panels and promote the sustainable development of the construction industry.

With years of manufacturing experience and technical accumulation, KINGREAL provides high-quality corrugated roof sheet machines to customers around the world, helping customers achieve the highest operational efficiency of construction projects. If you are interested in the corrugated metal roofing machine, please contact us immediately for more information.