What is light steel keel plasterboard partition?

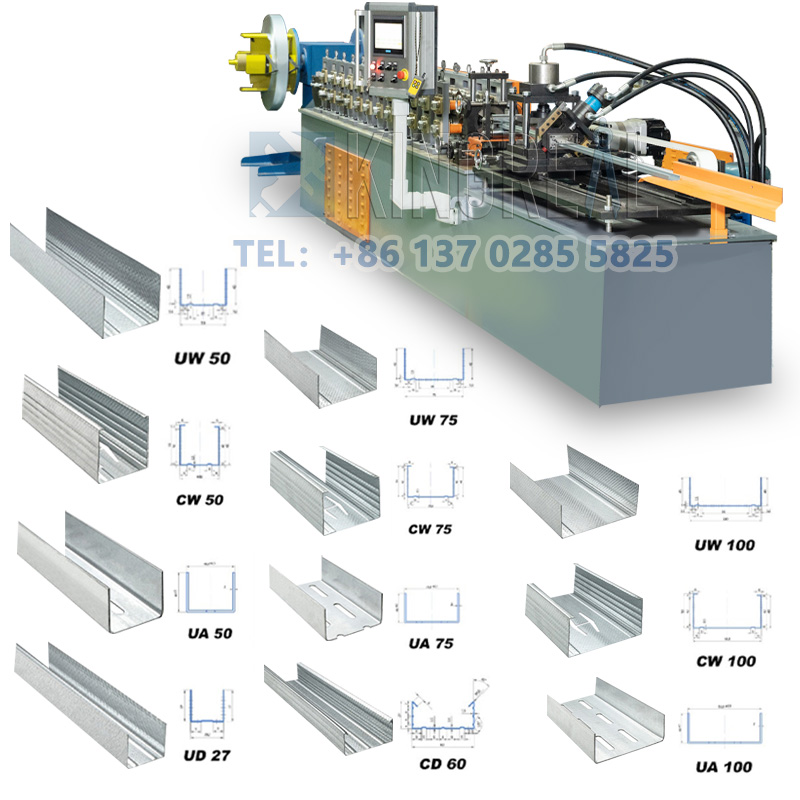

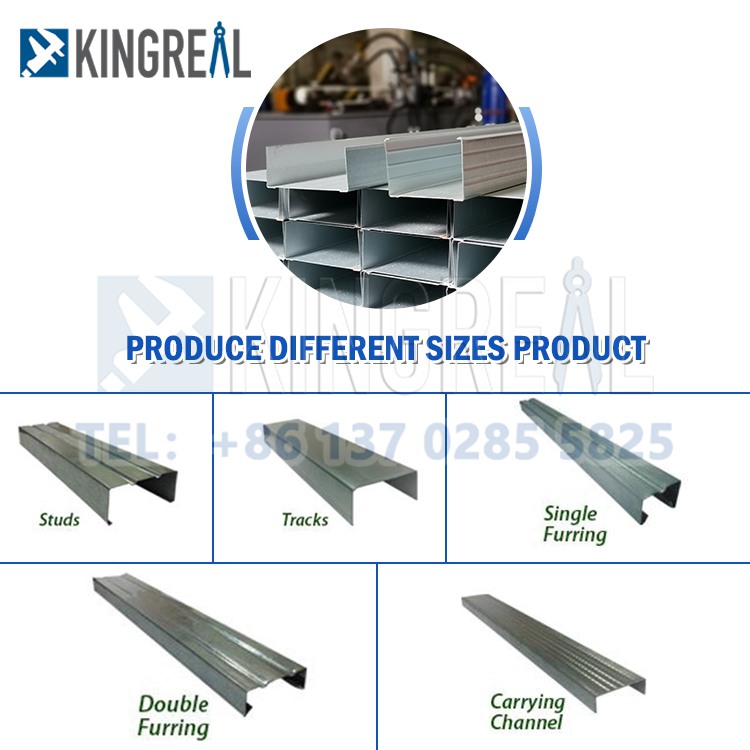

2024-11-27 11:49Stud and track is a metal framework for construction which is made of high quality continuous hot galvanized sheet strip and rolled through cold bending process by stud and track roll forming machine. It is used for modeling and decoration of non-load-bearing walls and roofs of buildings with light panels such as gypsum board and decorative gypsum board. It is suitable for the modeling and decoration of the roof of a variety of buildings, the basic materials of the internal and external walls of buildings and the trellis type suspended ceiling.

Advantages of stud and track keel gypsum board partition wall

1. The construction is convenient, fast, on-demand combination, sensitive division of space, and easy to remove. It can effectively save labor and speed up construction progress.

2. Light weight, strength to meet the requirements of use. The thickness of gypsum board is generally 9.5-15mm, and the weight per square meter is only 6-12kg. With two sheets of gypsum board sandwiched between stud and track light keels is a good partition wall, the weight of the wall per square meter is 23Kg, only about 1/10 of the ordinary brick wall. The gypsum board is used as interior wall material, and its strength can also meet the requirements. The longitudinal fracture load of 12mm gypsum board can reach more than 500N.

3. Decrease in revenue. The chemical and physical properties are stable, and the expansion rate is small in the process of dry moisture absorption.

4. Good decorative effect. The surface layer of the gypsum board partition wall can be compatible with a variety of surface layer decoration materials to meet the decoration requirements of most local buildings.

5. Economic and reasonable, reduce waste. Compared with the ordinary brick and concrete secondary construction wall, it prevents the chipping formed by the hydropower reserve and the plastering and leveling operation stopped because of the surface decoration practice, so that we omit the plaster and putty painting operation in the wallpaper decorative surface layer operation, so as to reduce the cost, shorten the construction period, save resources and prevent waste.

6. Energy conservation and environmental protection, policy support.

Classification of stud and track keel gypsum board partitions

Stud and track gypsum board partition wall according to the structure can be divided into single-row keel single-layer gypsum board partition wall, single-row keel double-layer gypsum board partition wall and double-row keel double-layer gypsum board partition wall, the former is used for general partition wall, the latter two are used for sound insulation wall.

Construction technology analysis

1. The wall cable

According to the design construction drawing, release the position line of the partition wall, the border line of the door and window opening, and put the edge line of the top keel position on the ground or the pillow belt that has been made;

2. Install the door opening frame

After pay-off, install the door opening frame of the partition wall according to the design

3. Install along the top keel and along the ground keel

According to the position line of the partition wall, install the top keel and ground keel according to the line, and fix them on the main body with shooting nails, and the shooting distance is 600mm;

4. Vertical keel classification

According to the position of the opening of the dividing wall, after the installation of the top keel, according to the specifications of the cover panel 900mm or 1200mm plate width, the size of the sub-scale specification is 450mm, the sub-scale with insufficient modulus should avoid the position of the first cover panel on the edge of the door frame, so that the broken edge gypsum cover panel is not near the hole frame;

5. Install vertical keel

Install the vertical keel according to the dividing position. Insert the upper and lower ends of the vertical keel into the top keel and the ground keel. After adjusting the vertical and positioning accurately, fix it with the core rivet; The keel on the side of the wall and column is fixed with nails or wood screws, and the nail distance is 1000mm;

6. Install the transverse keel card file

According to the design requirements, when the height of the partition wall is greater than 3m, the transverse clamp keel should be added, and the core drawing rivets or bolts should be fixed;

7. Install gypsum cover panel

(1) Check whether the keel installation quality, the door opening frame meets the design and structural requirements, and whether the keel spacing meets the modulus of the gypsum board width;

(2) The installation side of the gypsum board, starting from the door, the wall of the non-door opening starts from one end of the wall, gypsum board is generally fixed with self-tapping screws, the board edge nail distance is 200mm, the board distance is 300mm, the screw distance from the gypsum board edge shall not be less than 10mm, nor greater than 16mm, when the self-tapping screw is fixed, The drywall must be close to the keel;

(3) Install electrical tube, electrical box and electrical box equipment in the wall;

(4) Install fireproof, sound insulation and moisture-proof filling materials in the wall, and install and fill the gypsum board on the other side at the same time;

(5) Install the other side of the wall gypsum board: the installation method is the same as the first side gypsum board, the joint should be staggered with the first side panel;

(6) The installation of double-layer gypsum board: the fixing method of the second layer board is the same as that of the first layer, but the seam of the third layer board should be staggered with the first layer, and can not fall on the same keel with the seam of the first layer;

8. Construction joint practice

(1) the gypsum board joint practice has three forms, namely, flat seam, concave seam and lamination seam. The following procedures can be followed:

(2) Scraping the caulking putty: before scraping the caulking putty, remove the floating soil in the joint, use a small scraper to insert the putty into the plate seam, fill and scrape the board surface;

(3) Paste the binding tape: when the sealing putty solidifies in its original shape, the line paste the binding material. First scrape a thin layer of rubber putty of thin consistency on the joint, the thickness is 1mm, the width is the binding bandwidth, and then paste the binding tape, scrape it flat and compacting with a medium scraper from the top to the next direction, and drive out the bubbles between the adhesive putty and the binding tape;

(4) Scraping the middle layer putty: after the knot tape paste, immediately scrape a layer of middle layer putty with a width of about 1mm than the width of the knot about 80mm, so that the knot belt buried in this layer of putty;

(5) Leveling putty: use a large scraper to fill the putty wedge groove and smooth the plate;

9. Surface construction

Wall decoration, gypsum board wall, according to the design requirements, can do a variety of finishes.