What is the difference between a stud and a track?

2024-12-02 12:10In modern buildings, partition walls are an integral part of the spatial layout, providing privacy, sound insulation, fire prevention and other functions. The structure of the drywall is mainly composed of metal keels, of which the most common components are track and stud.

These two components are often used together, although their shape and function are different, but in the structure of the drywall each plays an irreplaceable role. So, what's the difference between Track and Stud? and how are they produced by stud and track roll forming machines? Let's explore.

What is Track?

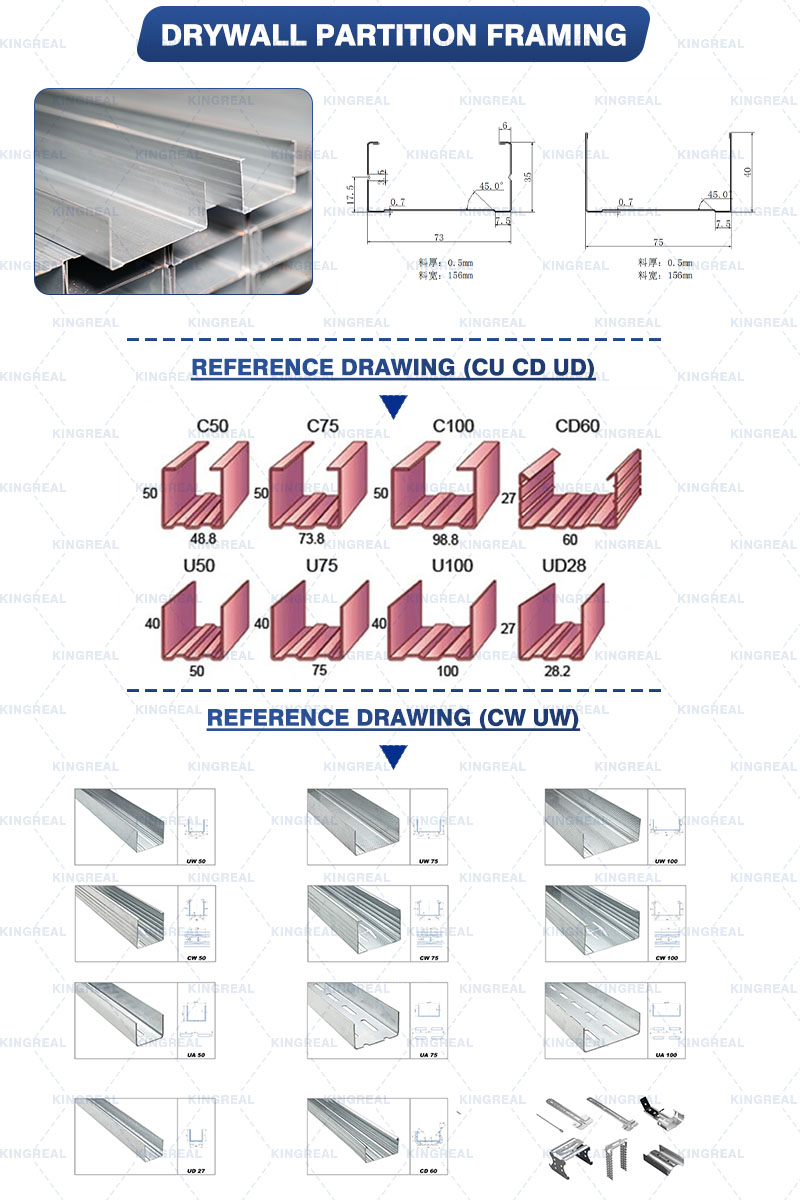

The Track is a horizontal component in the partition keel system that is installed at the bottom and top of the drywall. Its main function is to provide a fixed base for the stud. The track is usually a u - or c-shaped metal frame that is used to secure the stud to both ends of the wall, ensuring the stability and firmness of the partition. It provides the structural framework for the wall and ensures that the wall does not shift in the vertical direction.

Features of Track

1. Horizontal position: Track is usually installed on the ground and ceiling and extends along the length of the wall to form the supporting frame of the drywall.

2. Fixing function: Track is responsible for fixing the vertical Stud and playing the role of support and connection.

3. Simple structure: The design of Track is relatively simple, usually U-shaped or C-shaped, to ensure that the column can be firmly embedded and fixed.

What is Stud?

Stud are vertical components in the drywall system that sit between the tracks and carry and support the vertical structure of the wall. They are usually arranged at a certain spacing (for example, 400mm or 600mm) to support the weight of the wall and provide foundation support for other decorative or installation facilities. Stud is the main part of the drywall, usually made of metal material, with high strength and durability.

The characteristics of Stud

1. Vertical mounting: The Stud is mounted between the tracks, vertically arranged, and takes the load of the wall.

2. Load-bearing action: Stud is responsible for supporting the weight of walls, especially exterior walls or walls with other devices.

3. Diversity: Stud is usually C-shaped or U-shaped, and the size and thickness can be customized according to needs.

Main differences between Track and Stud

1. Position and direction

- Track: It is installed on the top and bottom of the wall and is a horizontal component.

- Stud: Installed between tracks and is a vertical component.

2. Function and effect

- Track: Mainly plays a fixed and supporting role, providing a mounting base for Stud.

- Stud: Responsible for supporting the weight of the wall and providing installation locations for other facilities.

3. Shape and design

- Track: This is usually a U or C shape for easy insertion and fixation of the Stud.

- Stud: Usually C-shaped or U-shaped, designed to pay more attention to bearing capacity and stability.

4. Installation method

- Track: Install on the ground and ceiling first, then insert Stud into it for fixing.

- Stud: Installed vertically between tracks according to design requirements.

5. Materials and specifications

- Track and Stud: Metal materials such as galvanized steel are usually used to ensure their strength and corrosion resistance. Specifications and dimensions are customized to meet different building needs.

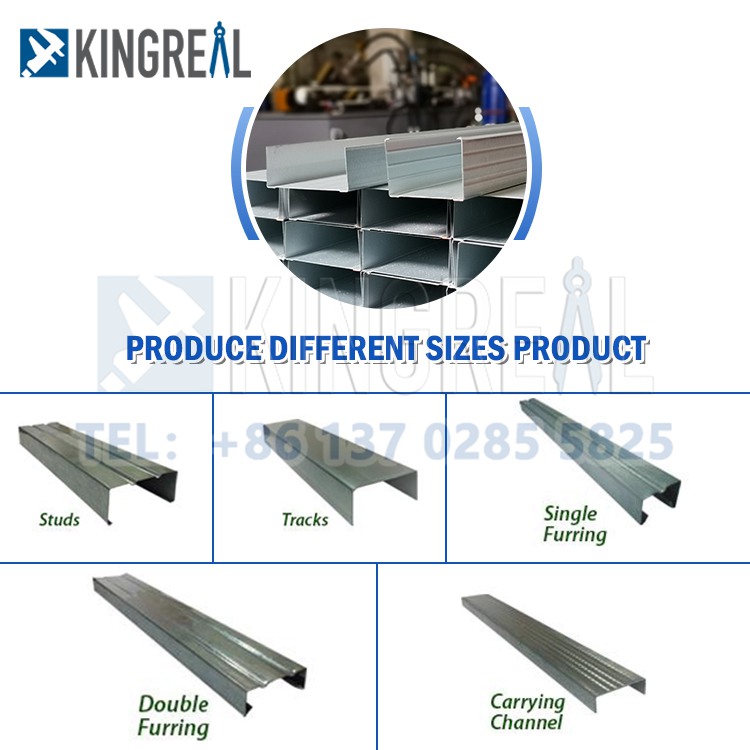

Description of Stud and track roll forming machine

Stud and Track Roll Forming Machine is an automated machine that efficiently process metal sheets into track and stud. Through this equipment, the components that meet the design requirements can be produced on a large scale and with high precision. Such equipment plays a vital role in improving production efficiency, reducing costs and ensuring product quality.

Advantages of gypsum channel roll forming machine

1. Efficient production: This equipment can continuously produce large quantities of Track and Stud, which greatly improves production efficiency.

2. High accuracy: Thanks to automated operation, the Track and Stud produced are accurate in size and meet industry standards, ensuring quality consistency.

3. Strong flexibility: the gypsum channel roll forming machine can usually adjust the specifications and shapes of the Track and Stud according to the needs, and can adapt to the requirements of different construction projects.

4. Save materials: Through the precise cutting and molding process, it can effectively reduce the waste of raw materials and improve the utilization of resources.

Factors to consider when choosing Track and Stud

1. Wall bearing requirements: For walls that need to bear larger loads, thicker and stronger Stud should be selected, and the specifications of the Track should be increased accordingly.

2. Fire and sound insulation requirements: where high sound insulation and fire performance are required, it is particularly important to choose the right material and thickness.

3. Construction environment: In wet or corrosive environments, Track and Stud using corrosion resistant materials such as galvanized steel can effectively improve their service life.

4. Production efficiency and cost: If it is a large-scale construction project, the use of Stud and Track Roll Forming Machine can significantly improve production efficiency, reduce labor costs and material waste.

Sum up

Track and Stud are the two key components of the drywall system, which bear the horizontal support and vertical load of the wall respectively. Through Stud and Track Roll Forming machines, manufacturers are able to produce these metal components efficiently and precisely, ensuring the quality and stability of the drywall. In the actual construction, choosing the right Track and Stud, combined with advanced production equipment, can not only improve the construction efficiency, but also meet the functional and aesthetic requirements of different construction projects.