What's shelf panel machine?

2025-01-26 12:04Definition of shelf panel machine

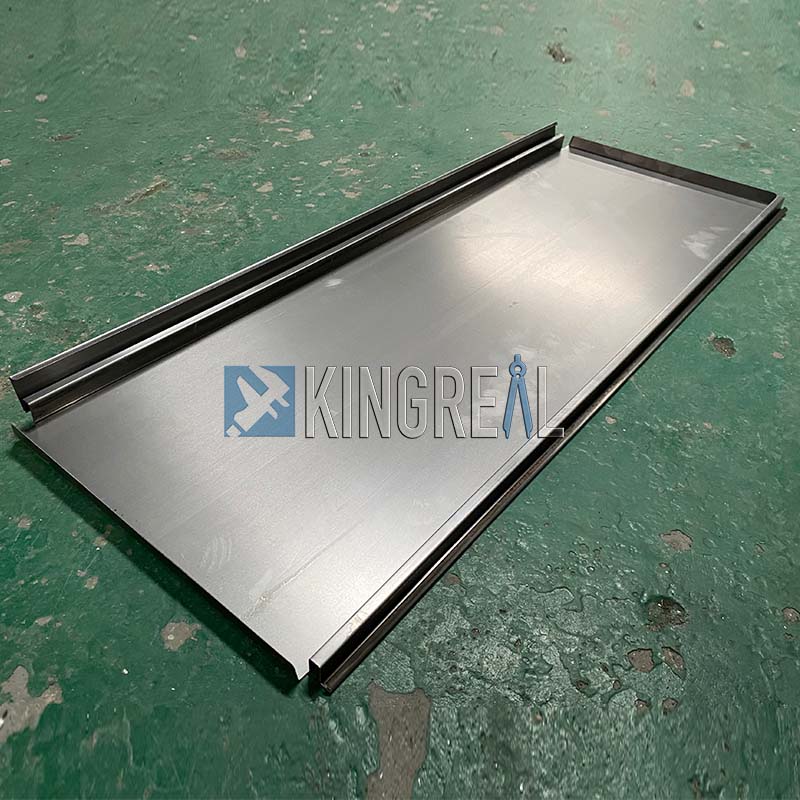

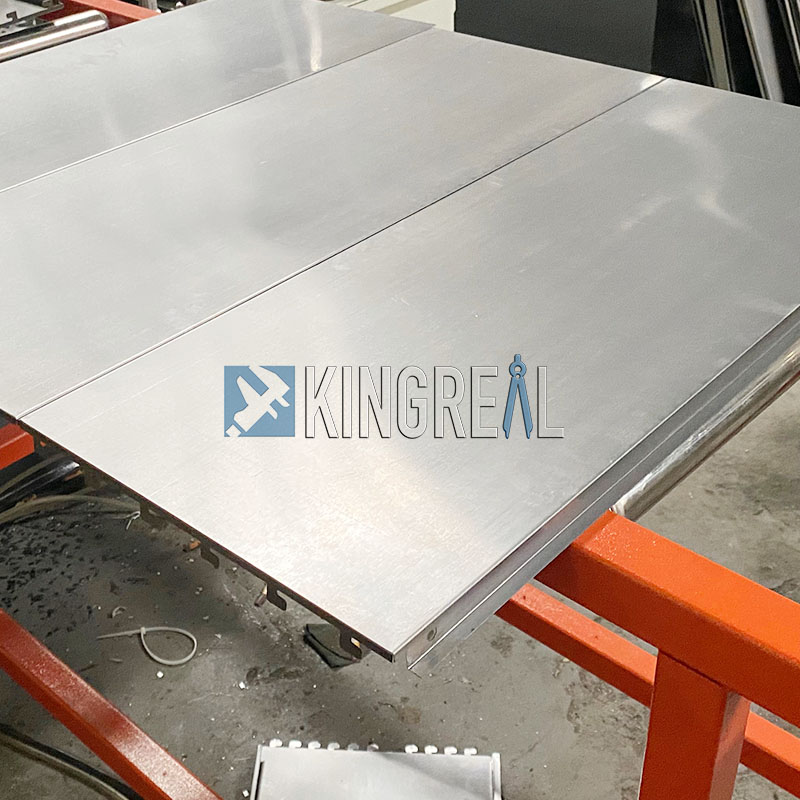

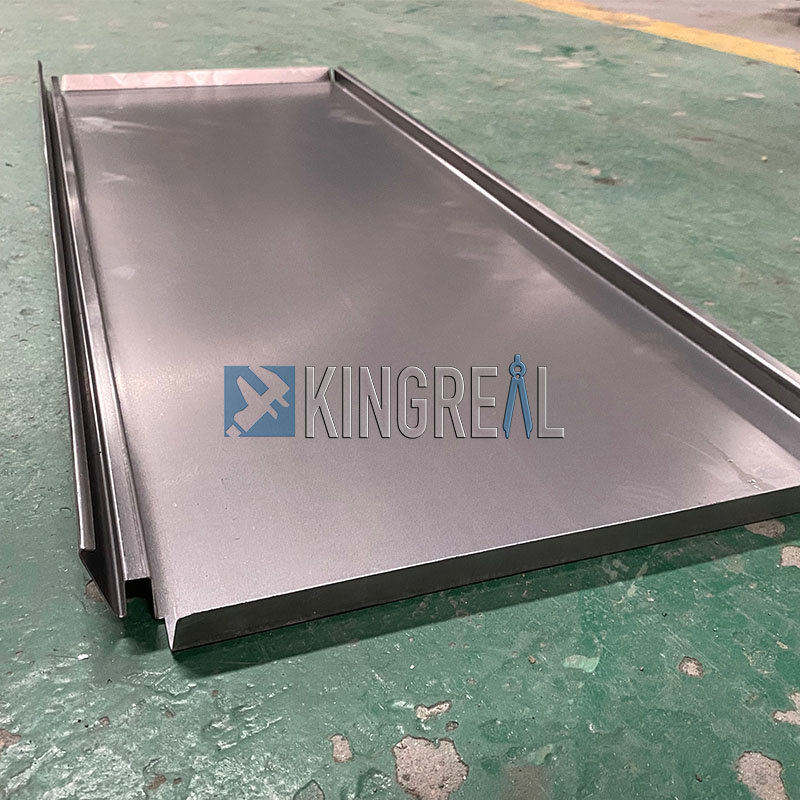

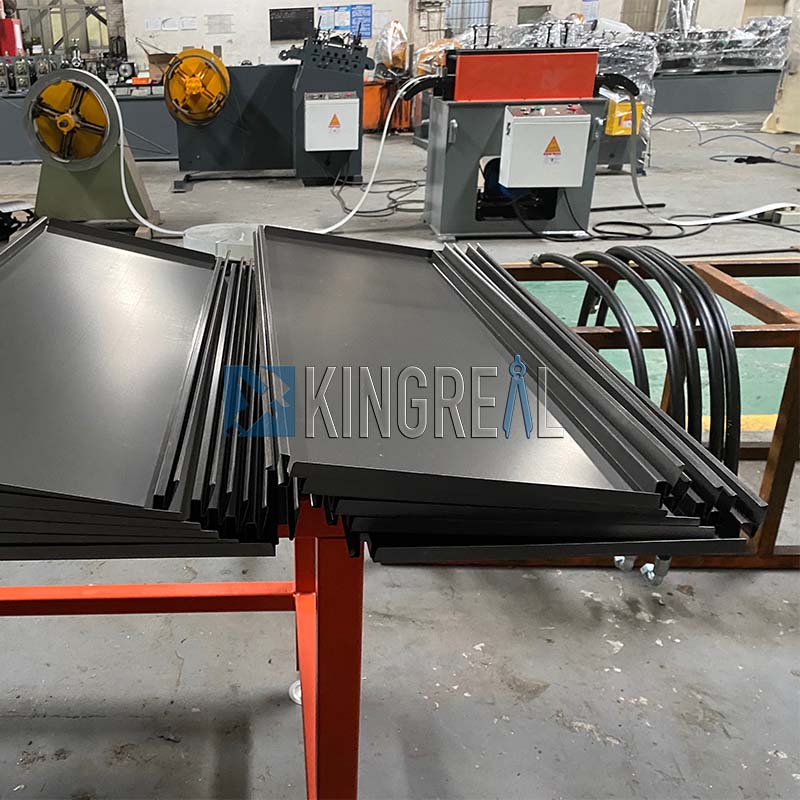

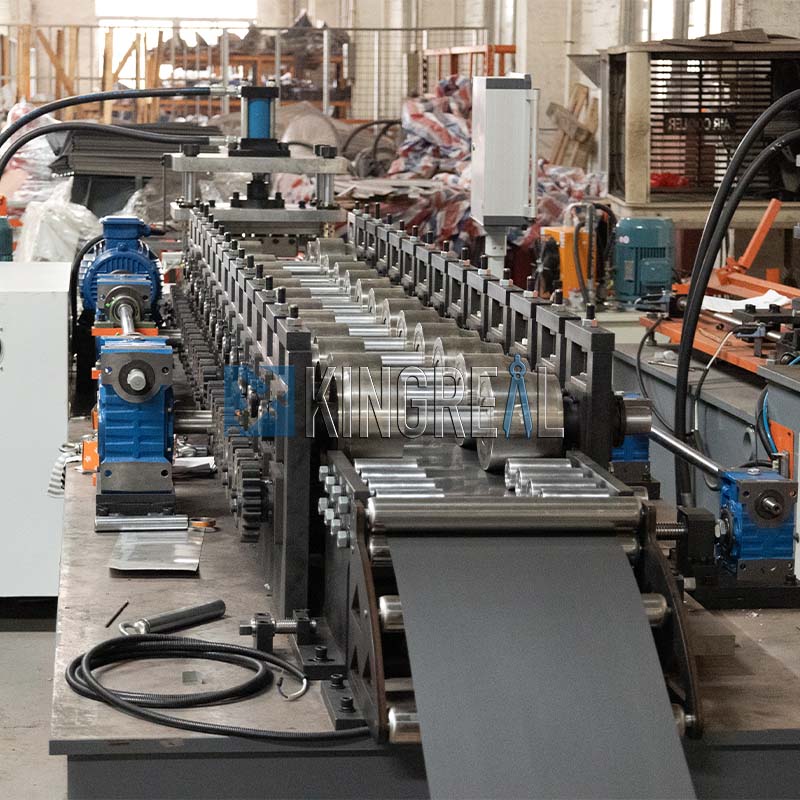

KINGREAL shelf panel machine is an efficient and precise industrial equipment designed for the production of shelf panels for a variety of storage and racking applications. The supermarket shelf panel machine takes a metal coil (usually steel or aluminum) and forms it through a series of processing steps to a specific profile that meets shelf requirements.

Due to the advantages of cost-effectiveness, high strength and durability, metal shelves are widely used in stores, supermarkets, warehouses, factories and other scenes, and are deeply favored by users.

KINGREAL supermarket shelf panel machines are known for their easy operation, long service life, fast production speed and high precision of finished products, and are widely praised by customers.

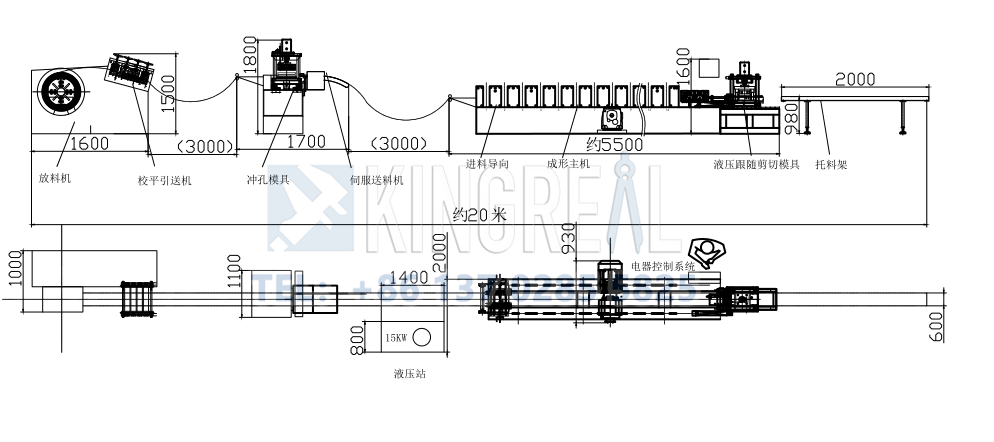

Components of the supermarket shelf panel machine

KINGREAL shelf panel machine consists of the following core components, each of which has been carefully designed to ensure efficient operation of the equipment and quality of the finished product:

2-in-1 decoiler & precision straightener

The decoiler is an automated machine that unwinds the metal coil to provide a stable supply of raw materials for subsequent processing. And the precision straightener is used to level the metal coil to eliminate the corrugation and unevenness on its surface, ensuring the flatness of the material during processing.

Hydraulic Punching Station

According to the design requirements of the shelf panel, the metal plate is accurately punched to meet the diversity of shelf installation and functions.

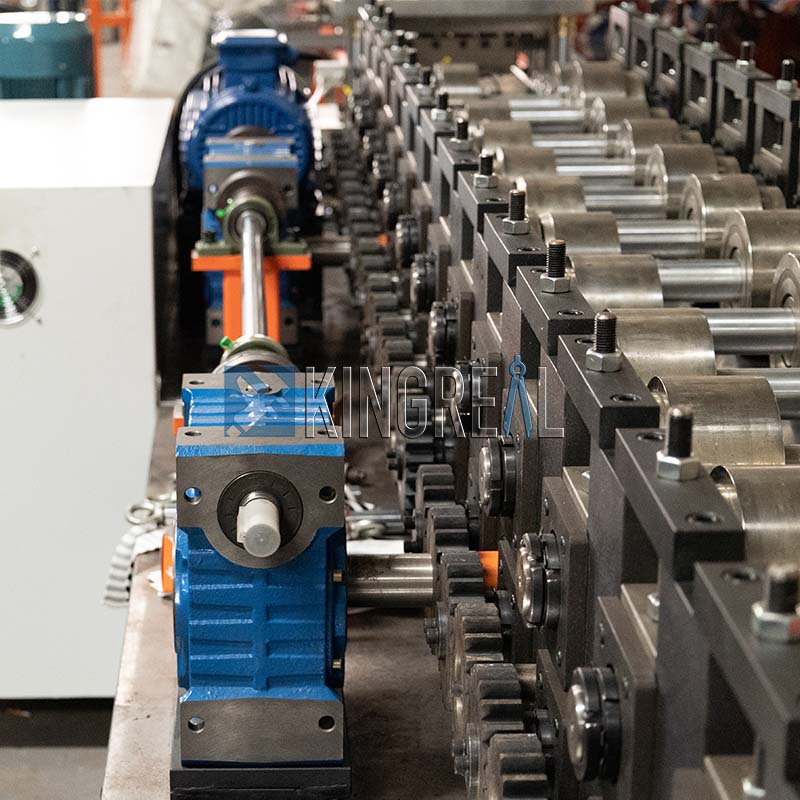

Main Roll Forming Machine

The main forming machine is the core component of the shelf panel machine. Through a series of high-strength roller groups, the metal sheet is gradually pressed and formed to form a specific profile of the shelf panel.

Shearing Station

Specially used to accurately cut the length of the shelf panel according to the specific needs of the customer.

Working process of shelf panel machine

Unwinding--flattening--punching--forming--folding & cutting

Advantages of supermarket shelf panel machine

2-in-1 decoiler & precision straightener

KINGREAL innovatively integrates the decoiler and precision straightener, providing customers with an efficient and space-saving solution. Traditional shelf panel machines usually need to be equipped with decoilers and levelers separately, which takes up more factory space, and the connection between equipment can easily lead to reduced efficiency.

The 2-in-1 design of KINGREAL not only simplifies the equipment layout, but also significantly improves production efficiency by optimizing material transfer. At the same time, this design reduces material waste in the intermediate links and further reduces production costs.

Fully automated equipment

KINGREAL shelf panel machine adopts a fully automated design and is equipped with an advanced PLC control system and intelligent sensors. The user only needs to set the parameters on the control panel, and the equipment can complete the entire process from uncoiling, leveling, punching to forming and shearing.

This fully automated operation mode brings the following significant advantages:

- Reduce labor costs: No need for a large number of operators, only one person is needed to monitor the operation of the equipment.

- Reduce safety hazards: Fully automated equipment avoids the risk of manual intervention in the production line and improves operational safety.

- Improve production efficiency: Automated processes can maintain continuous and efficient production and minimize downtime.

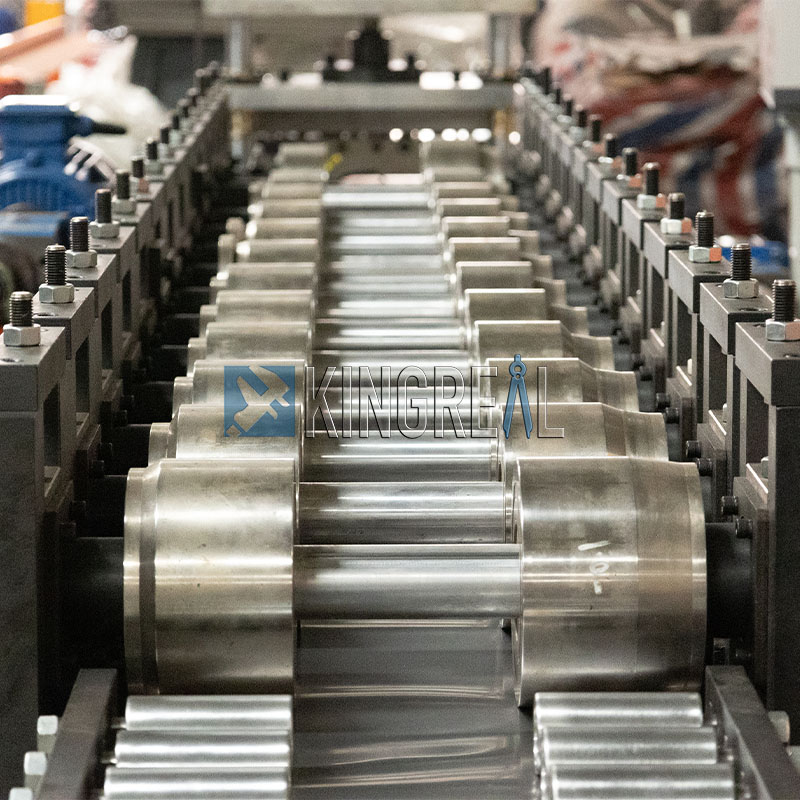

High-strength roller set

The roller assembly of the forming machine is the core component of the shelf panel forming, which directly affects the quality of the finished product and the service life of the equipment. KINGREAL's roller set is made of 40mm thick spindle and CR12MOV mold steel. After strict quenching and hardening treatment, it has the following characteristics:

- High hardness and wear resistance: The roller can withstand high-intensity operations for a long time without deformation, ensuring the continuity and stability of production.

- Precision molding: The roller assembly is precisely processed to ensure that the molding dimensions of the shelf panel are accurate and meet high-standard production requirements.

- Long service life: High-quality materials and exquisite workmanship give the roller set an extremely long service life, reducing the cost of equipment maintenance and replacement.

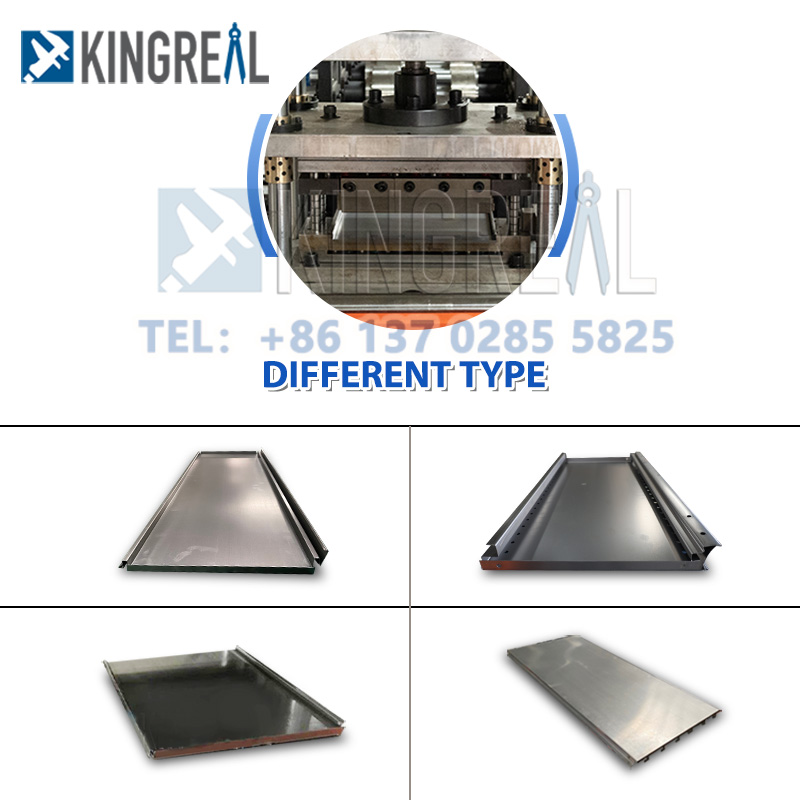

Support multi-size production

The design of KINGREAL supermarket shelf panel machine is very flexible. By adjusting the rollers and replacing some molds, the equipment can easily adapt to the production needs of shelf panels of different sizes. This versatility provides customers with the following benefits:

- Meet diverse needs: One production line can meet the production of shelf panels of different specifications and adapt to the diverse order needs of customers.

- Reduced equipment investment: Customers do not need to configure separate production equipment for each size of product, which greatly reduces the initial investment cost.

- Quickly switch production: The process of adjusting the roller is simple and quick, and the size can be switched in a short time, ensuring that production efficiency is not affected.

Flexible solutions

KINGREAL is fully aware of the diverse needs that customers face during the production process and therefore provides highly customized solutions. Whether it is production speed, raw material thickness, molding width, or budget range, KINGREAL can tailor the best production line configuration for customers. For example:

- Speed range: The machine supports different production speed options, to meet the needs of mass production.

- Material adaptation: According to customer needs, the equipment can process metal sheets of different thicknesses and materials, including stainless steel, aluminum, cold-rolled steel, etc.

- Price flexibility: KINGREAL offers equipment options at a variety of price points to ensure that companies of different sizes can find a production solution that suits them.