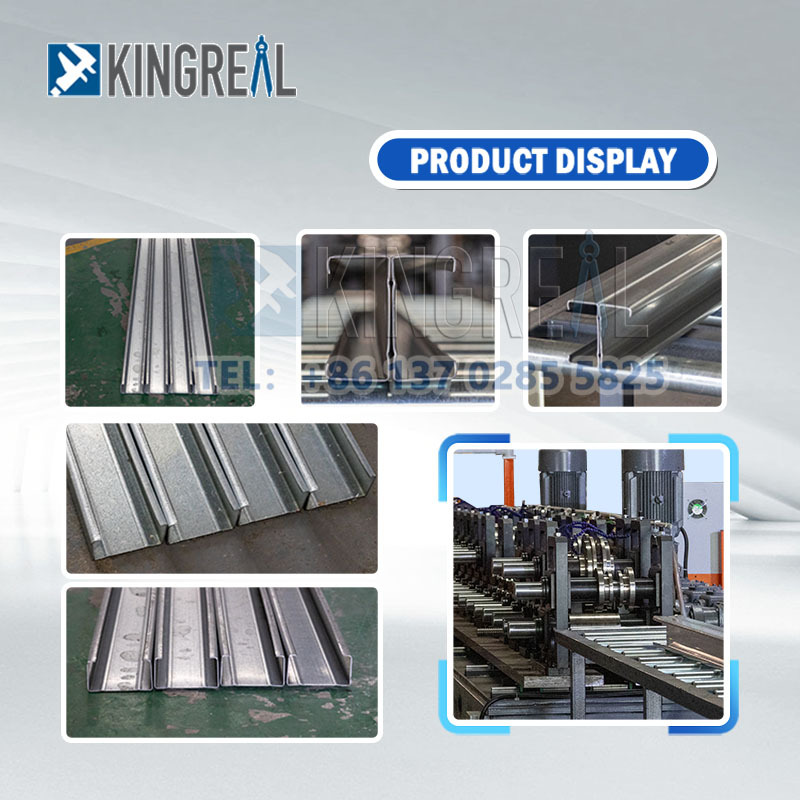

C Purlin Roll Forming Machine

KINGREAL MACHINERY is able to provide customers with C Purlin Roll Forming Machine design and production solutions.C Purlin Making Machine is equipped with 15 chain-driven roll forming stations to ensure production efficiency and accuracy of C Purlin products, solving customers' production goals for long-lasting C Purlin production goals for long-lasting benefits.

- Information

- Download

Description Of C Purlin Roll Forming Machine

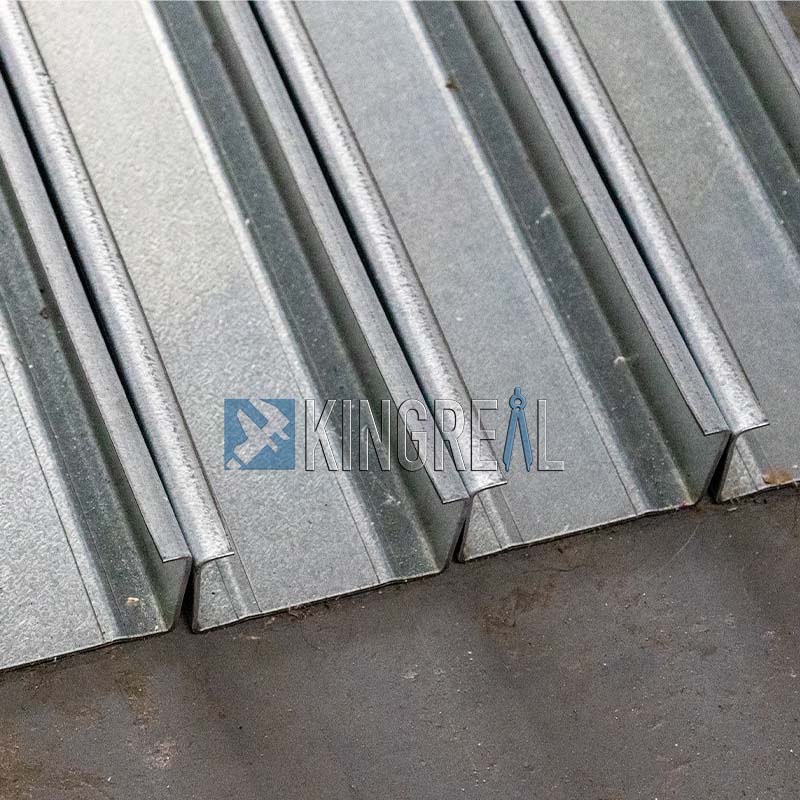

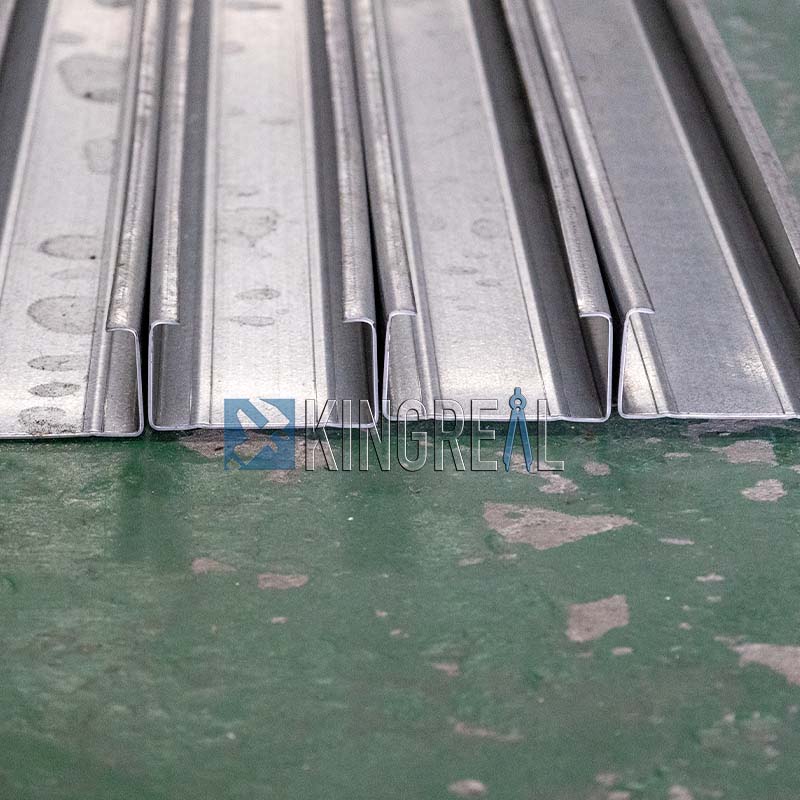

KINGREAL MACHINERY C Purlin Roll Forming Machine is design for produce the different size c purlin. Generally speaking the C purlin is a cold-formed thin-walled steel member with a letter“C“cross-section, which is a widely used structural material in construction and industry.

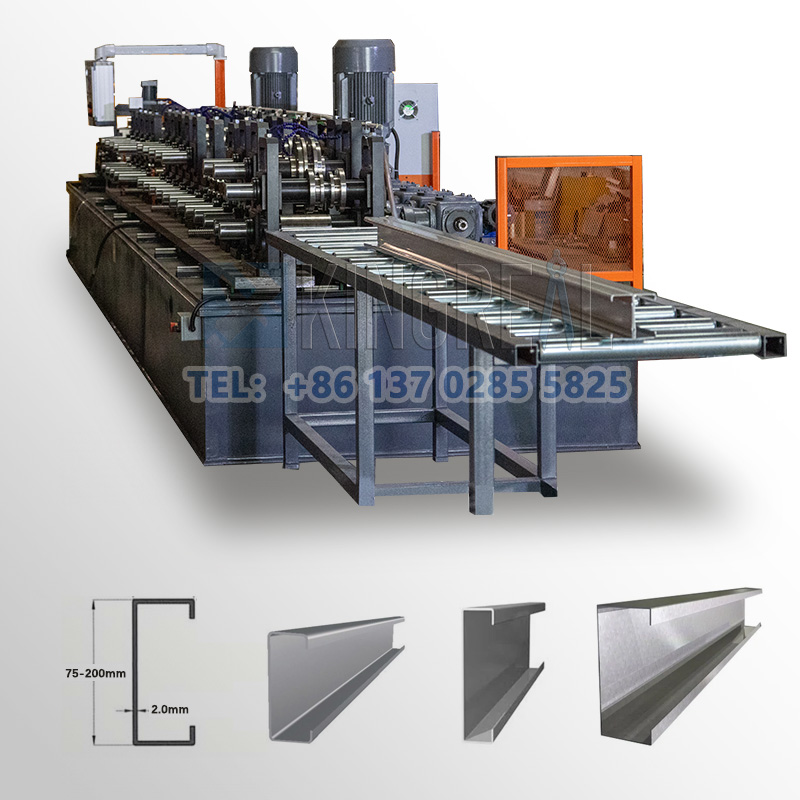

KINGREAL MACHINERY C Purlin Making Machine can continuously roll steel strips or coils with a thickness of 1.5-3.0mm into C-section steel through cold bending forming process, with a forming speed of up to 18 meters/minute. KINGREAL MACHINERY equips the metal purlin making machine with encoder length measurement and touch screen operation interface to ensure that the wall thickness of the c purlin product is uniform to meet the complex production of the c purlin cross-section shape.

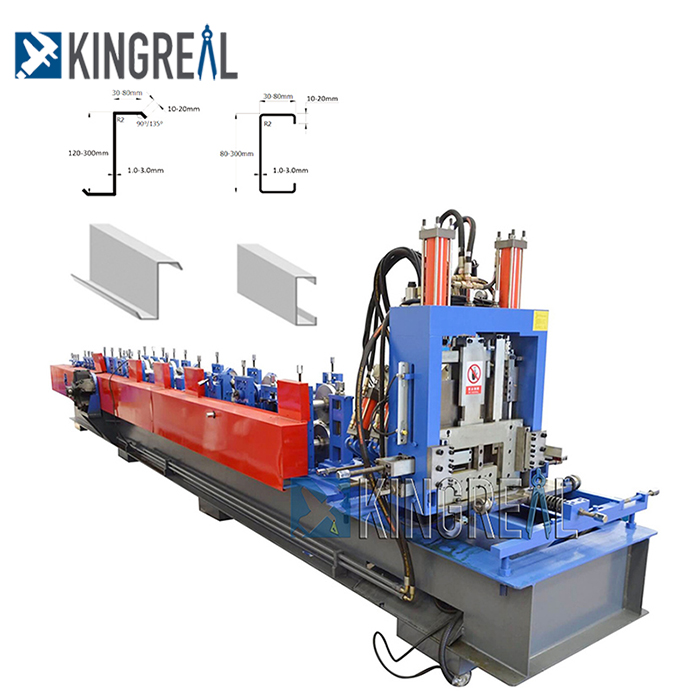

KINGREAL MACHINERY can also provide CZ Purlin Roll Forming Machine models for compatible production of C-type and Z-type steel (CZ Adjustable type), and the machine servo-driven electric type change equipment can be replaced to meet the requirements of different specifications. KINGREAL ROLL FORMER is committed to providing customers with CZ Purlin Making Machine production solutions, including single-specification models and multi-specification models that can reasonably match the production needs of small production workshops and large processing plants for metal cz purlin products, improve competitiveness in the local market, and obtain long-term production benefits.

C purlin product application areas

Building structure: used as roof load-bearing purlins or wall support components for buildings such as factories, warehouses, and gymnasiums

Industrial manufacturing: used to manufacture cold-formed steel products such as containers, steel formwork, and automotive parts

Infrastructure: used in transmission towers, bridges, solar brackets, and other scenarios

About CZ Purlin Roll Forming Machine

KINGREAL MACHINERY Design CZ Purlin Making Machine is used to meet the needs of efficient, standardized and automated production of light steel structure components in modern buildings and steel structure projects. CZ purlin making machines usually have an automatic changeover function, which can quickly switch between C and Z types and different sizes to meet the diverse needs of different projects for purlins. It is suitable for factory batch production and meets the needs of large-scale use of purlins in modern building steel structures, especially in industrial plants, logistics warehouses, and commercial buildings.

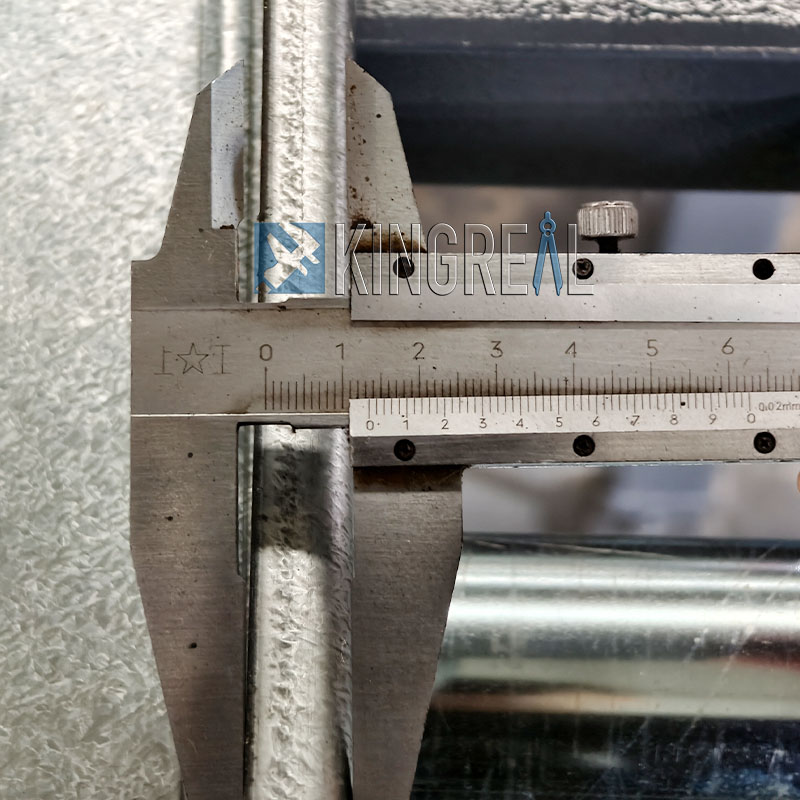

Compared with traditional single-specification metal purlin equipment, CZ Purlin Making Machine usually uses 12-18 sets of precision rollers, and the front 7-roller straightening machine eliminates the internal stress of the steel coil, with a straightness error of ≤0.3mm/m, preventing subsequent roller offset, and realizing a progressive bending process to shape the steel strip into a C/Z-shaped section. The roller geometric parameters need to be dynamically adjusted according to the material thickness and section size to ensure a forming accuracy of ±0.5mm. CZ Purlin Roll Forming Machine uses a variable frequency motor with a reducer to achieve stepless speed regulation of 0-25 meters/minute to ensure the stability of the forming process.

Working Process Of C Purlin Making Machine

Decoiler -- Feeding And Leveling -- Main Roll Forming Machine -- Hydraulic Punching And Cutting Station -- Product Support Frame

“KINGREAL MACHINERY supports customized design of different C Purlin Making Machine configurations according to customer production needs”

Specification Of C Purlin Roll Forming Machine

1.Raw Material: Q195, Q235 hot-rolled steel strip or hot-rolled galvanized steel strip

2.Coil Thickness: 1.5-3.0MM

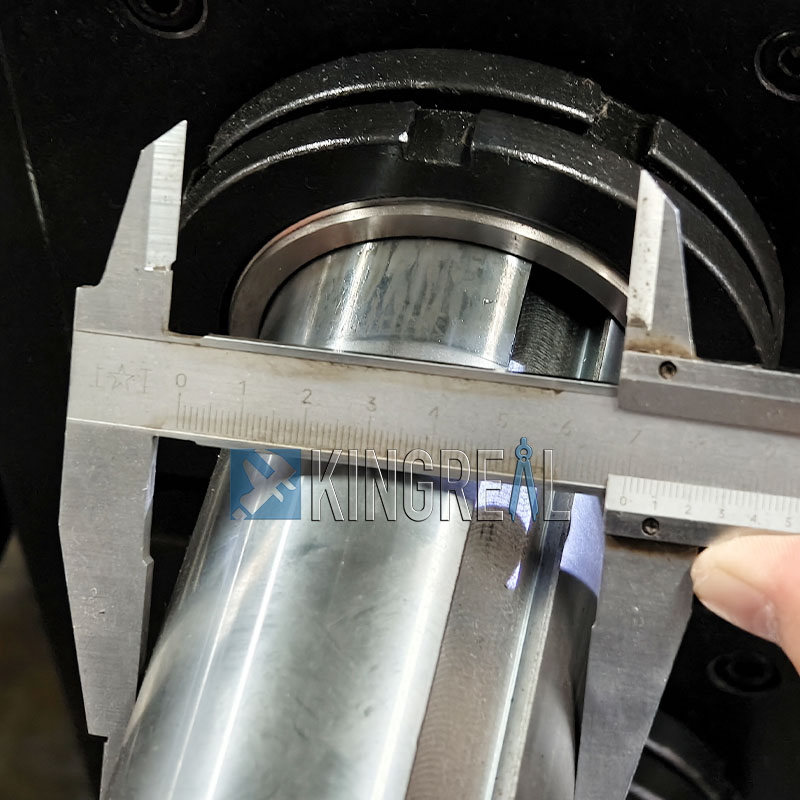

3.Roller Material: GCr15

4.Main shaft material: 40Cr

5.Discharging speed: High speed 30 m/min (depending on the number of holes)

6.Product specifications: .①C width (80-300mm), Z width (120-300mm) can be changed arbitrarily; ②Waist height (40-80mm) can be changed arbitrarily; ③Small edge (10-20mm); ④Slab thickness t (1.5-3.0mm) can be adjusted

Common Component Of C Purlin Production Line

Decoiler

The decoiler in the C Purlin Making Machine is the front-end feeding system of the whole set of equipment. Its main function is to carry and release the coiled steel strip to provide continuous raw materials for the subsequent forming process.

- Carrying capacity: 3 tons, 5 tons, 10 tons, etc.

- Applicable coil width: 100~600mm (customizable)

- Applicable inner diameter: usually φ450-550mm

- Decoiler speed: match the whole line forming speed (usually 10~15 meters/minute)

Feeding And Leveling Device

The feeding and leveling device in the C Purlin Making Machine is an important front section of the entire production line. It is located between the unwinder and the roller press main machine. It is mainly responsible for accurately, smoothly and neatly feeding the unwinding steel strip into the forming machine, providing high-quality raw material foundation for the subsequent cold bending forming process.

Material thickness: 1.5 – 3.0 mm

Material width: 80 – 300 mm

Number of leveling rollers: 7 rollers, 9 rollers, 11 rollers

Drive mode: electric, servo motor

Accuracy requirement: ±0.5 mm (for punching)

Hydraulic Punching And Cutting Station

The Hydraulic Punching and Cutting Station in the C Purlin Making Machine is the punching and cutting module of the entire production line. It is mainly used to punch out bolt holes, mounting holes and other structural holes before or after C-shaped steel is formed and cut the continuously formed C-shaped purlins into single pieces according to the set length.

Core components:

1. The hydraulic station provides a high-pressure hydraulic power source to drive the punching cylinder and the cutting cylinder

2. The punching die can be customized according to the hole type and installed on the punching frame. It can punch a single hole or multiple holes at the same time

3. The cutting die is generally a flying shear or a fixed-length shear to ensure that the shearing surface is vertical and flat without burrs

4. The servo/encoder positioning system ensures the position accuracy of punching and cutting, realizes PLC linkage control, and can automatically arrange holes according to the drawings

Roll Forming Machine

The Main Roll Forming Unit in the C Purlin Making Machine is the core of the entire production line. It is responsible for continuously cold-bending the flattened and punched steel strip through multiple rollers to finally form the required C-shaped purlin section.

Forming passes: 12 – 20 (depending on the section size)

Applicable material thickness: 1.5 – 3.0 mm

Forming speed: 10 – 15 m/min (high end can reach more than 20m/min)

Forming accuracy: within ±0.5 mm

Adjustable size range: C80 – C300 (bandwidth/edge height adjustable)

Drive mode: gearbox, chain, motor direct drive

Quality Control For C Purlin Making Machine

“KINGREAL MACHINERY is a professional roll forming machine manufacturer in China. We have been focusing on the design and production of various roll forming machines for more than 20 years. We can provide customers with complete production solutions, and are committed to helping customers achieve long-term production benefits and providing worry-free after-sales service.”

Contact us now to get the latest C Purlin Making Machine production solutions!