Metal Roof Tile Machine

KINGREAL can provide various design metal roof tile machine which are used to construct roofs,such as corrugated roll forming machine, ibr making machine, standing seam machine, snap lock metal roof tile machine, ridge cap roll forming machine, glazed tile roll forming machine, double layer roll forming machine,etc.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video About Metal Roof Tile Machine

KINGREAL offers a wide variety of metal roof tile machines to meet customers' needs for a complete system of roof tiles. The main advantage of metal roof tiles is their lightness. Metal roof tiles do not cause excessive burden on the roof structure and do not affect the structure of the entire building. This has important economic benefits when replacing roof panels during house construction and renovation. And because the roof tiles are easy to install, they are loved by African countries such as South Africa and Zimbabwe.

KINGREAL metal roof making machines provide a variety of solutions for customers who are looking for differentiated roof applications. If you have questions about the parameters of KINGREAL metal roof making machines or need more information, please contact us!

Types of Metal Roof Sheet Making Machine

KINGREAL can provide customers with a variety of metal roof panel machines, including:

Metal Roof Making Machine

Corrugated Roll Forming Machine

Standing Seam Machine

Snap Lock Metal Roof Making Machine

Ridge Cap Roll Forming Machine

Glazed Tile Roll Forming Machine

Double Layer Roll Forming Machine

Roofing Tile Roll Forming Machine

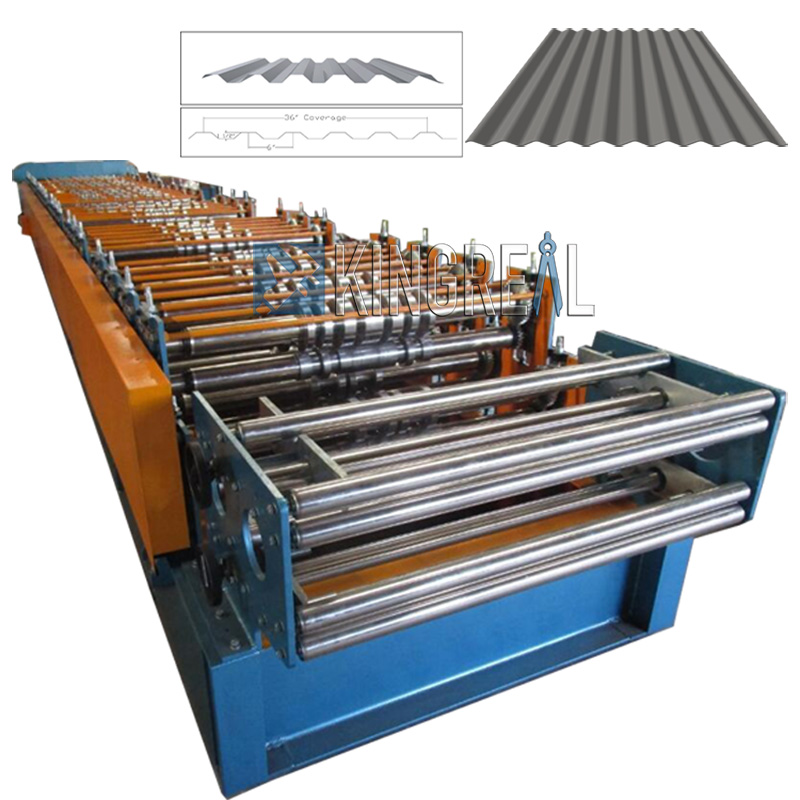

Corrugated Roll Forming Machine

KINGREAL corrugated roll forming machine is an efficient metal roof making machine, mainly used to produce corrugated metal roofing sheets. Corrugated tiles are widely used in residential and industrial buildings due to their unique design. Compared with traditional tiles, corrugated tiles have better earthquake resistance and will not slide easily during an earthquake, thus reducing the risk of injury. At the same time, due to its lightweight characteristics, it can reduce the overall burden of the building.

KINGREAL corrugated sheet roll forming machine can handle a variety of raw materials, including color pre-coated rolls, galvanized steel rolls, and other types of metal sheets. This flexibility makes the machine popular with many customers and can meet the needs of different markets.

Corrugated roofing sheets are widely used in residential, warehouse, farm, industrial plant and other places. Its superior waterproof performance and UV resistance make it the preferred material for many construction projects.

Advantages of corrugated sheet rolling machine

- High efficiency: The corrugated sheet rolling machine is reasonably designed and has a fast production speed, which can quickly meet the needs of large-scale production.

- Earthquake resistance: The special corrugated design enhances its earthquake resistance and is suitable for use in earthquake-prone areas.

- Lightweight load-bearing: Reduces the overall weight of the building and reduces the cost of infrastructure construction.

IBR Making Machine

IBR forming machine, also known as Inverted Box Rib forming machine, is specially used to produce IBR roof tiles. KINGREAL provides two common specifications of IBR forming machines, 686 and 890, which are widely used in the construction industry.

IBR roof tiles are known for their high strength and corrosion resistance, which can withstand harsh weather conditions and extend their service life. Such tiles are also available in a variety of colors and materials to meet the personalized needs of customers. IBR roof panels are widely used in commercial buildings, industrial plants, warehouses and residential areas. Its structural characteristics and aesthetics make it a popular choice for modern buildings.

Advantages of IBR Making Machine

- Diversity: IBR roof tiles of various specifications and styles can be produced to meet the needs of different customers.

- Durability: The IBR Making Machine is designed to be sturdy to ensure long-term stable operation and provide customers with efficient production capabilities.

Glazed Tile Roll Forming Machine

KINGREAL glazed tile roll forming machine, also known as step tile forming machine, can produce metal glazed tiles with similar appearance to traditional clay tiles, while enhancing their durability and weather resistance. The machine automatically feeds and presses metal sheets into the desired shape, and can produce glazed tiles of different thicknesses and colors to meet the various needs of customers.

Glazed tiles are suitable for residences, villas, courtyards and other places, and are loved for their elegant appearance and good performance.

Advantages of Glazed Tile Roll Forming Machine

- Realistic appearance: glazed tiles that perfectly replicate the appearance of traditional clay tiles can be produced, while having the durability of modern materials.

- Diverse options: Thickness and color can be adjusted according to customer needs to meet personalized needs.

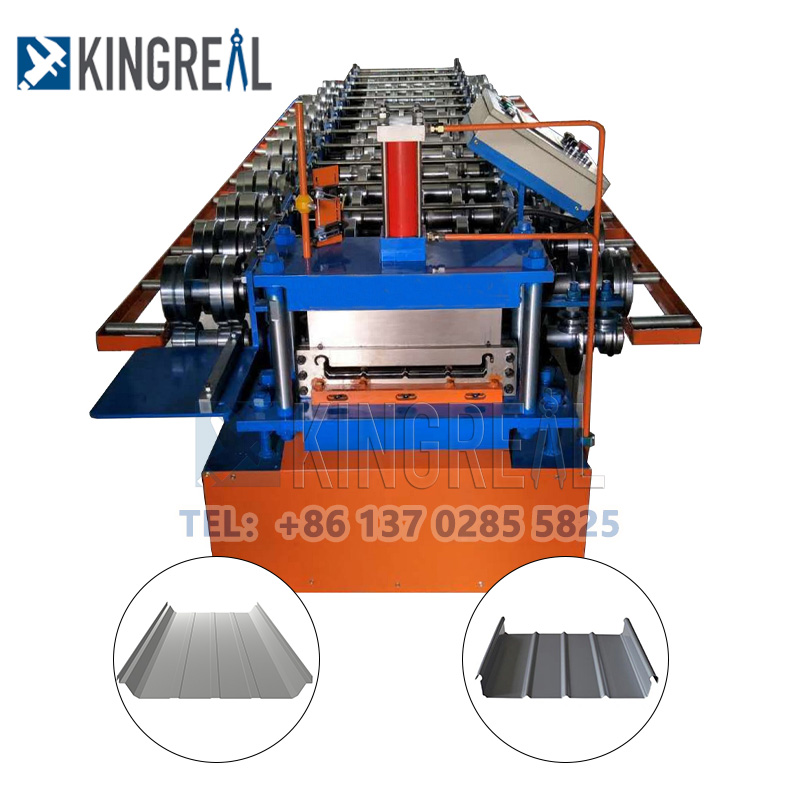

Standing Seam Machine

KINGREAL standing seam forming machine adopts a fully automatic design and is specially developed for the production of standing seam roof panels. The machine uses rollers made of high-quality 45 steel, which are processed by CNC lathe and heat treated to ensure its durability. Optional hard chrome plating process can be used to further extend the service life.

Standing seam roof panels are widely used in commercial buildings, industrial plants and high-end residences, etc., and are favored for their excellent air tightness and waterproofness.

Advantages of Standing Seam

- Good air tightness: effectively prevent leakage and ensure the safety of the roof.

- Strong load-bearing performance: suitable for various weather conditions, ensuring long-term stable use.

Snap Lock Metal Roof Making Machine

KINGREAL snap lock metal roof forming machine is suitable for residential and light commercial applications. Its unique design makes the installation process simple and fast.

The strength of the panel comes from its snap-on design. The hidden fastener system can effectively absorb the defects of the roof and provide better stability.

This roof panel is suitable for residential, commercial buildings and light structures. It is widely popular because of its easy installation and maintenance.

Advantages of Snap Lock

- Easy installation: The panel connection is simple, saving construction time.

- High strength: The snap-on design enhances its structural strength and is suitable for use in various environments.

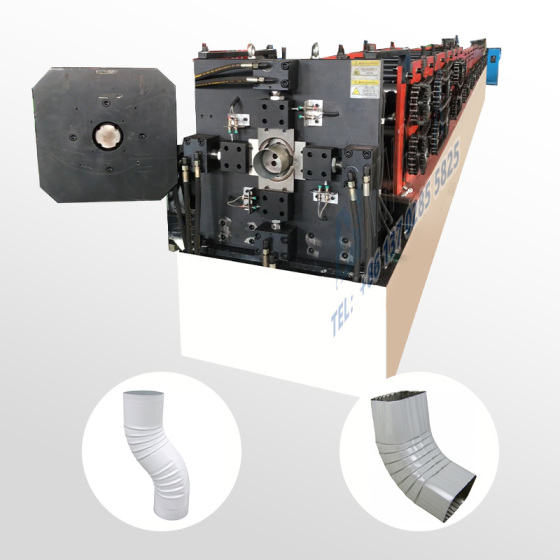

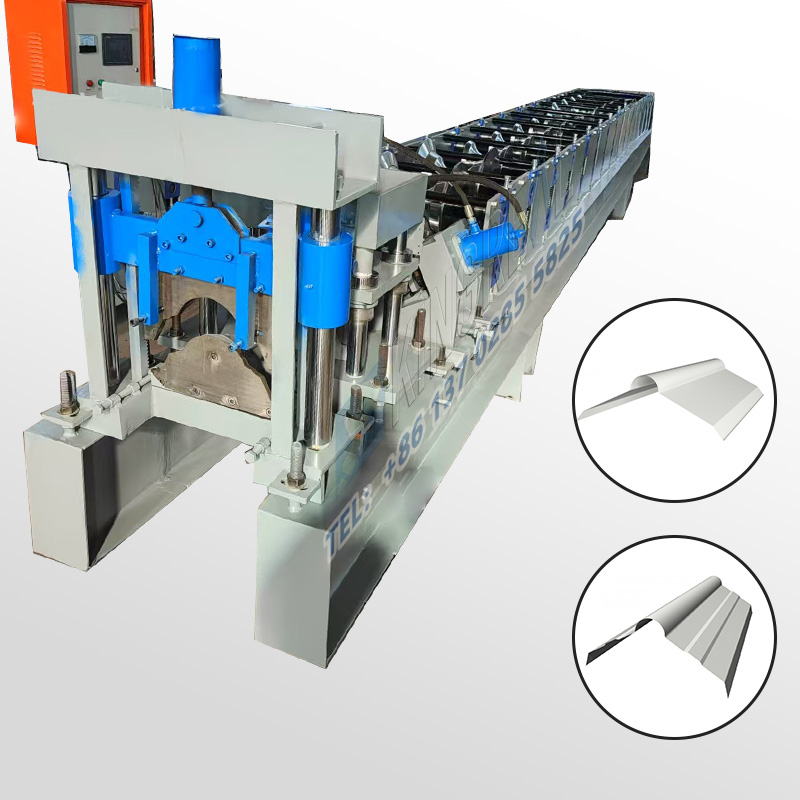

Ridge Cap Roll Forming Machine

KINGREAL ridge cap roll forming machine can be used to manufacture ridge cap profiles of various shapes and sizes, effectively protecting the ridge from wind and rain. The machine can produce curved or specific angle ridge caps according to customer needs, ensuring that it can adapt to various roof designs.

Ridge caps are widely used in residential, commercial buildings and industrial plants to protect the ridge from natural factors.

Advantages of Ridge Cap

- Strong customization ability: It can produce ridge caps of different shapes and sizes according to specific needs.

- Good protection performance: It effectively prevents damage to the ridge part and extends the service life of the roof.

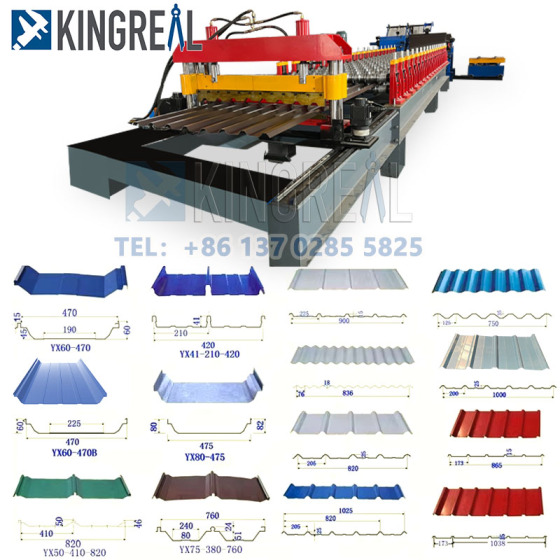

Double Layer Roll Forming Machine

KINGREAL double layer roll forming machine can freely combine two models according to customer needs, and one machine can produce two different types of tiles at the same time. This design enables customers to efficiently produce different types of tiles on the same machine, reducing equipment investment and operating costs.

Double layer roll forming machine is suitable for customers who need diversified products, such as construction companies, material suppliers, etc.

Advantages of double layer roll forming machine

- Economical and practical: one machine can produce multiple products, reducing equipment investment.

- High flexibility: the production type can be quickly adjusted according to market demand.

Parameters of Metal Roof Making Machine

Corrugated Roll Forming Machine

Working Material | Coated Steel , Galvanized Steel etc |

Thickness Range | 0.4 – 1 mm |

Working Width | 1300 mm Maximu |

Maximum Coil Weight | 12T |

Roll Forming Station Qty | 18 roll forming stations (Opt.) |

Roll Forming Speed | 0-35 m/min |

IBR Making Machine

| Quantity of forming rollers stations | 20 |

| Diameter of forming rollers shafts | 75mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material Cutter material | No.45 steel, coated with chromed treatment |

| CR12 mould steel, with quenched treatment | |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 7.5kw |

| Hydraulic unit motor power: 3kw | |

| Electric voltage | According to customer's requirement |

Standing seam machine

| Type of material to be processed | PPGL / PPGI / NCGI |

| Yield strength | 350 MPA (Max.) |

| Length of profile sheet | No limit |

| No of station | 15 ( Including Side Roll ) |

| Total connected power required | 18 HP |

| Coil Width range | 300 mm to 800 mm |

| Coil Thickness range | 0.4 mm to 0.7mm |

| Coil weight | 5 Ton |

| Production line speed (Without Cutting) | 0 to20MPM |

| Production line speed (With Cutting) | 0 To 12mtr/min (Without Cutting ) |

| 2 Ton Per Hour /Material Thickness 0.50 | |

| Automation level in performance | P.L.C. controlled length |

| Accuracy level | Length: ±2 M.M. |

Glazed Tile Machine

| Item | Parameters |

| Coil thickness (mm) | 0.4-0.6 |

| Roll stand | 16 |

| Main power (Kw) | 5.5 |

| Main shaft (mm) | Φ70 |

| Cutter material | Cr12 |

| Cutting accuracy | 10±2mm |

| Hydraulic station power (Kw) | 4 |

| Control system | PLC |

| Main machine dimension (mm) | 9600x1600x800 |

Snap Lock Machine

| Length | 94 Inches with shear (238.8cm) |

| Width | 41 Inches (104cm) |

| Weight | 1600 Pounds (725.5kg) |

| Power supply | 1HP, 110 Volt, 15Amp, T.E.F.C |

| Speed | 35 Feet (10.668m) per/minute |

| Decoiler capacity | 3000 Pounds (1360.3kg) |

| Materials | 24 to 26 gauge steel, 0.027 aluminum, 16 oz copper |

| Coil widths | 16 Inch (406.4mm), 20Inch (508mm) |

Ridge Cap Machine

| Specification | Optional |

Suitable material | Type:Galvanized Coil, PPGI, Carbon steel Coi |

Thickness(mm):0.3-0.8 | |

Yield strength: 250 - 550MP | |

Tensil stress( Mpa):G350Mpa-G550Mpa | |

Nominal forming speed(m/min) | 10-25 |

Forming station | 14 |

Rollers’ materal | Steel #45 |

Station structure | Wall panel station |

Punching system | No |

Cutting system | Post-cutting |

Power supply requirement | 380V 60Hz |

Double layer roll forming machine

| Model Application | floor deck and roofing |

| Type | Roll Forming Machine |

| Brand Name | KINGREAL |

| Applicable Materials | PPGI |

| Forming Speed | 20-25m/min |

| Place of Origin | China |

Other Machines Related to Metal Roof Making Machines

Downspout Machine

Gutter Making Machine

Metal Deck Roll Forming Machine

In the modern construction industry, metal roof making machines are not only the core equipment for roofing material production, but other related machines also play a vital role. KINGREAL provides a range of supporting equipment to provide customers with a complete metal roof tile system. These equipment not only improve production efficiency, but also ensure the overall quality and aesthetics of the building. The following are several major machines closely related to tile machines.

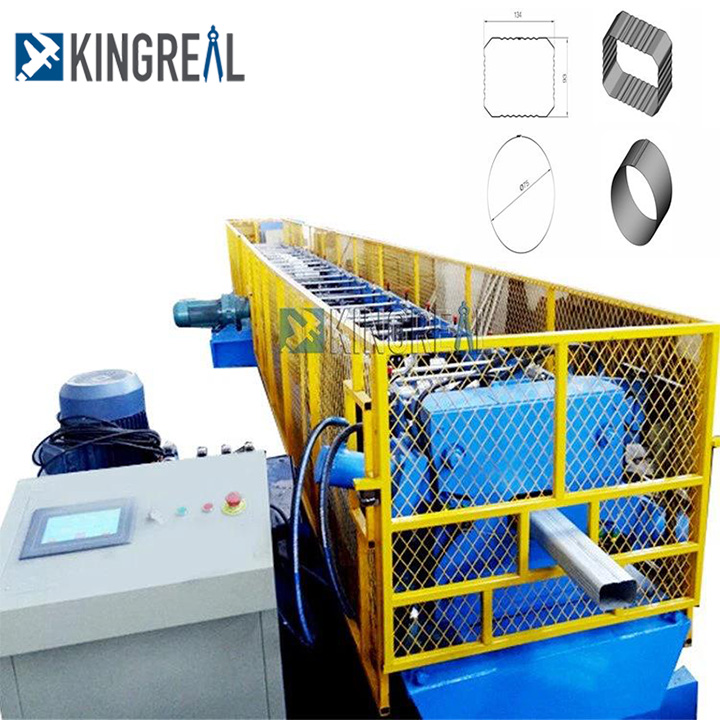

Downspout Machine

Downspout machines are used to produce pipes that guide rainwater from the roof to the ground. These pipes are usually installed on the edge of the roof and can effectively collect rainwater to prevent water flow from damaging the exterior walls of the building. KINGREAL downspout machine is flexible in design and can produce rainwater pipes of various diameters and shapes to meet the requirements of different buildings.

Downspout Machine uses a high-precision roll-forming process to ensure that the size of each rainwater pipe is accurate. The production process is simple and efficient, and a large number of products can usually be manufactured in a short time. In addition, the machine also has automatic operation functions, which reduces manual intervention and improves production efficiency.

Downspout machine is widely used in residential, commercial and industrial buildings to ensure the smooth drainage of rainwater and protect the integrity and safety of the building structure. By using high-quality Downspout machine, water leakage and water accumulation can be effectively prevented, and the service life of the building can be extended.

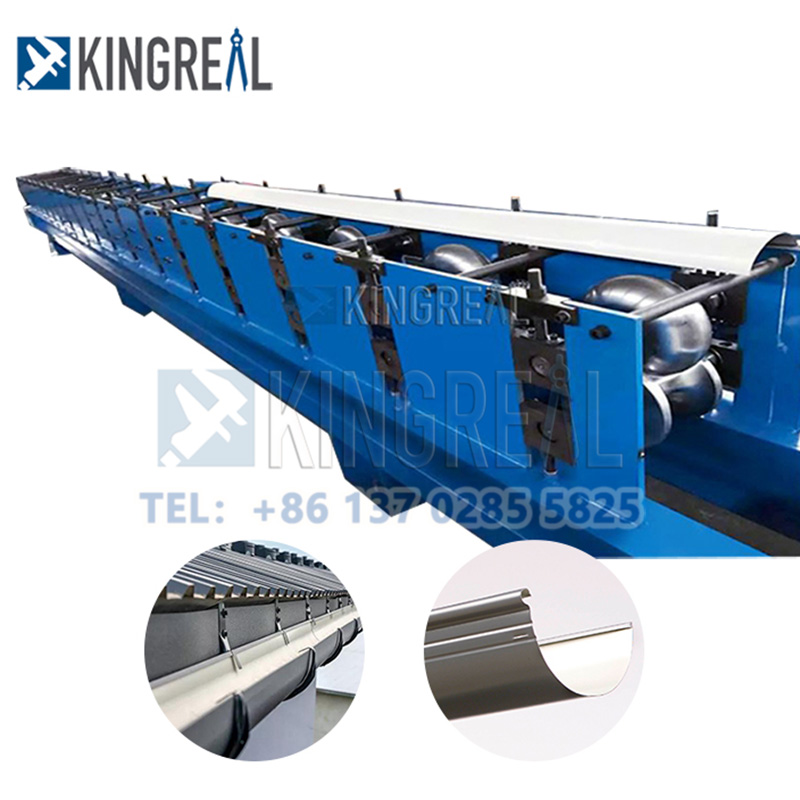

Gutter Making Machine

KINGREAL Gutter Making Machine is specially used to produce metal gutters, which are used to guide and drain rainwater from the roof to prevent leakage. The design and material selection of gutters are crucial to the waterproof performance of the building.

Different types of Gutter Making Machines can produce gutters of various specifications to meet the needs of different buildings. The machine is made of high-strength materials, which are corrosion-resistant and weather-resistant to ensure long-term and stable use. In addition, KINGREAL gutter making machine is equipped with an advanced automatic control system, which makes the operation easier and users can easily master the use of the machine.

Metal gutters are widely used in residential, commercial buildings, industrial plants and other fields. By effectively guiding rainwater, metal gutters can prevent water damage to buildings, protect walls and infrastructure from erosion, and also improve the aesthetics of buildings.

Metal Deck Roll Forming Machine

KINGREAL metal deck roll forming machine is a device dedicated to the production of floor decks, which can meet the diverse needs of load-bearing structures in modern buildings. As the basic supporting material of the floor, the floor deck bears the upper structure and people's daily activities, and its quality directly affects the safety and stability of the building.

The production speed can reach up to 25 meters per minute, which greatly improves production efficiency. The Metal Deck Roll Forming Machine is flexible in design and can adjust the specifications of the floor deck produced according to customer needs to meet the needs of different projects. At the same time, the strength and stability of metal floor decks make it highly respected in the construction industry.

Metal floor decks are widely used in commercial buildings, industrial plants, high-rise buildings and other fields. They are not only used for the load-bearing of floors, but also provide temporary support during the construction process, facilitating construction and subsequent decoration operations. By using high-quality metal floor decks, builders can ensure the safety and durability of the building while optimizing the construction period.