UAE 60X60CM Square False Metal Ceiling Tile Production Line - Semi Auto Solution

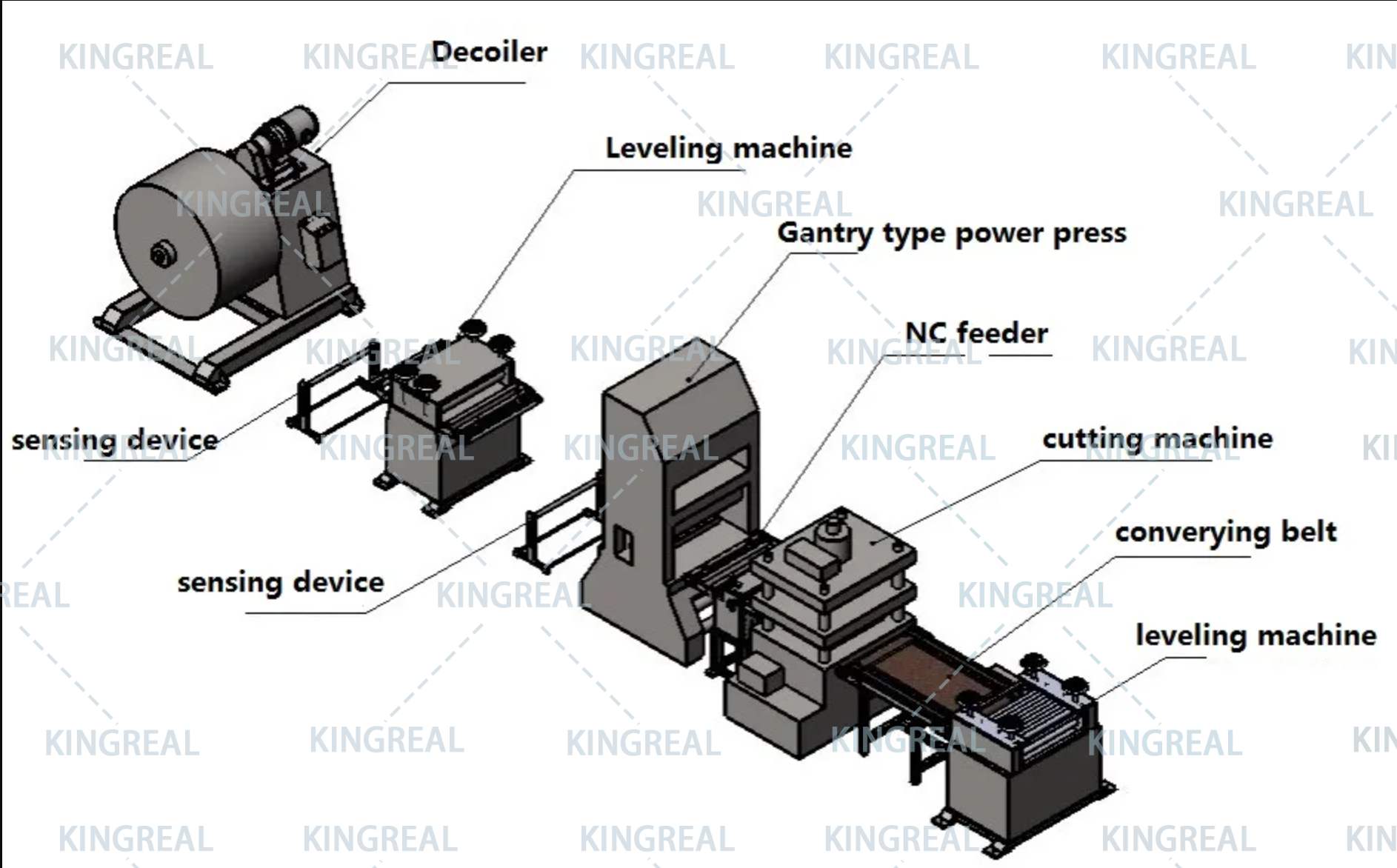

KINGREALUAE 60X60CM Square False Metal Ceiling Tile Production Line - Semi Auto Solution used for the production of different kinds decoration ceiling tiles and it adopt automatic material input, first flattening, holes punching, servo feeding, cutting to length, conveyor, second flatting, corner cutting and manual punch forming.

- KINGREAL

- China

- 100 Days

- 9999

- Information

- Download

Video About Semi Auto Metal Ceiling Tile Machine

Video About Semi Auto Metal Ceiling Tile Machine

Ceiling Tile Production Line Description

KINGREAL 60X60CM ALuminum Ceiling Tile Production line is mainly used for the production of different kinds decoration ceiling tiles and it adopt automatic material input, first flattening, holes punching, servo feeding, cutting to length, conveyor, second flatting, corner cutting and manual punch forming.

Metal Ceiling tile making machine is widely used in making aluminium or galvanized steel false ceiling tile, etc. with size of 600x600mm, 300x300mm or 1200x600mm. It is a fully automatic ceiling tile production line, mainly composed of decoiler, straightener, perforating press, servo feeder & hydraulic press. PLC controlled. 1 operator is required for 1 whole production line, which can realize high productivityand less manpower. The high speed perforation ceiling tile production line is featuring with full automatic, high precision, fast production speed and few operation workers. Which is first choice for the decoration material factories.

Process Of Metal Ceiling Production Line

Decoiling→ Straightening→Perforating→ Feeding→ Corner & Length Cutting→ Straightening (optional) → Automatic 4 sides bending.

Technical Specification

List | Item | Parameter | Quantity | Remark |

| 1 | Thickness (max) | 0.4-0.8mm | / | Aluminum |

| 2 | Thickness (max) | 0.4-0.6mm | / | G.I. |

| 3 | Size of product (mm) | 600*600, 300*450, 600*300, 600*1200 | / | Can open material 600×1200 |

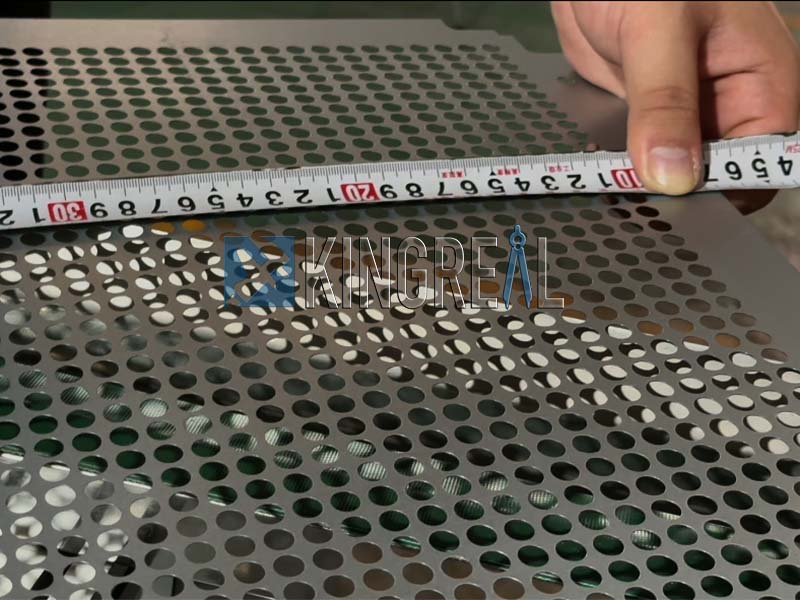

| 4 | Diameter of hole | φ1.8 | / | / |

| 5 | Speed | 2-2.5pcs/min | / | / |

| 6 | Max loading weight of decoiler | 3T | / | Load material by manual |

| 7 | Motor of decoiler | 3KW | 1 set | / |

| 8 | Motor of first level | 3KW | 1 set | / |

| 9 | Motor of feed material | 1.8KW | 1 set | / |

| 10 | Motor of second level | 3 KW | 1 set | / |

| 11 | Motor of oil pressure machine | 11 KW | 1 set | / |

| 12 | Motor of punching machine | 7.5 KW | 1 set | / |

| 13 | Motor of machinery hand | 1.0 KW | 2 set | / |

| 14 | Motor of transmit belt | 0.55 KW | 2 set | / |

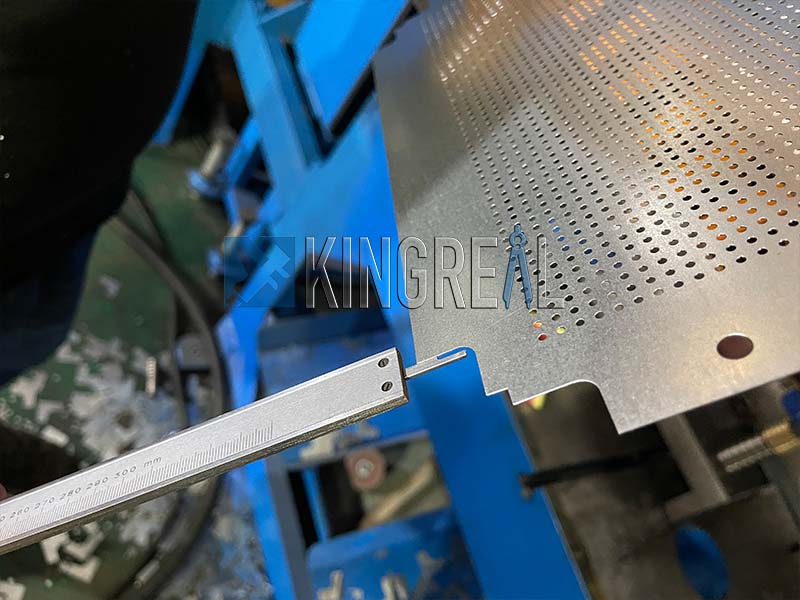

Ceiling Tile Product Display

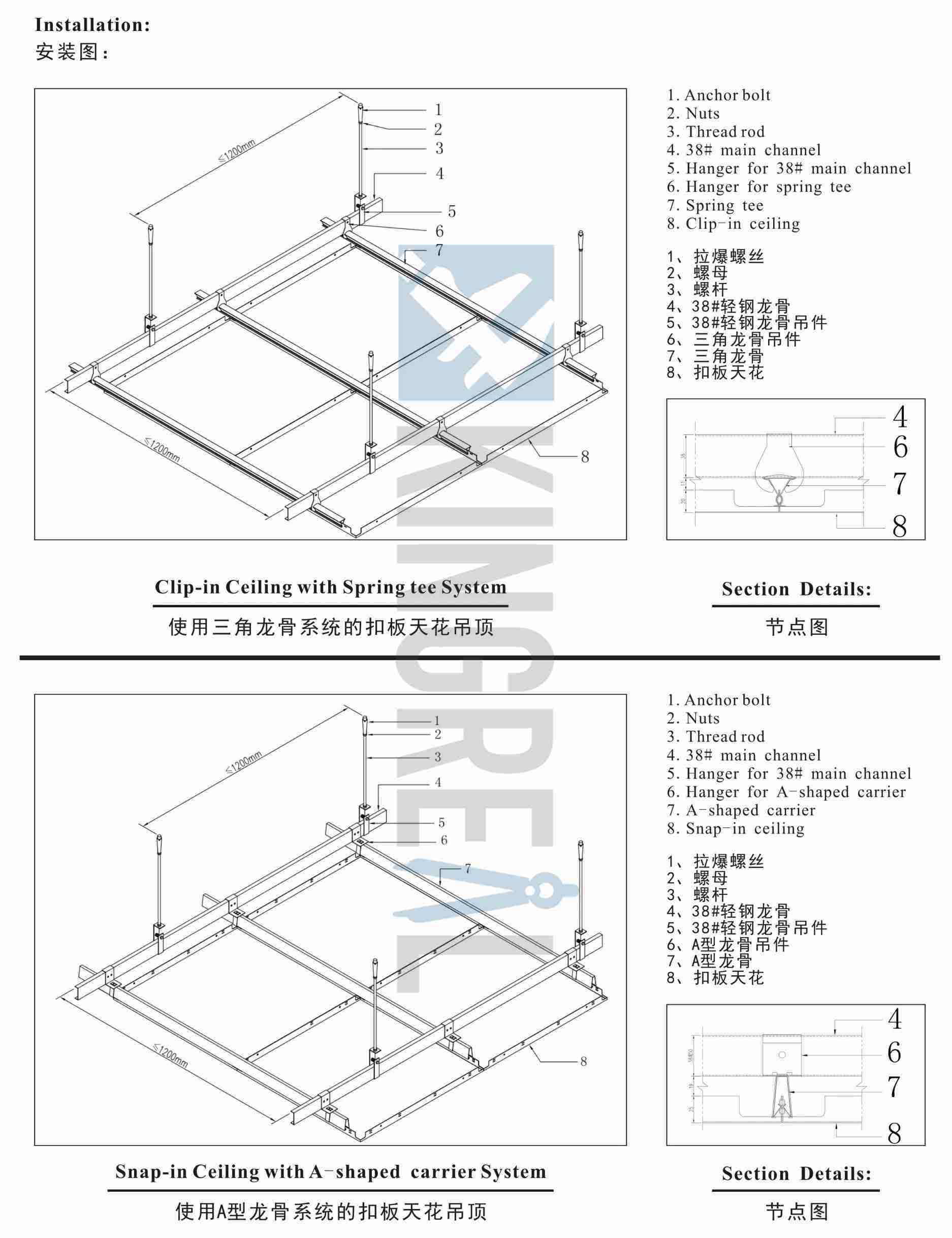

KINGREAL full automatic ceiling tile production line can produce different type of ceiling tile such as 600*600MM clip in ceiling tile, 600*1200MM long aluminum celing tiles, 300*300MM clip in ceiling tiles, 595*595MM layin Boards and etc. Beside perforated ceiling tiles, KINGREAL can also use this machine to produce plain ceiling tiles without perforation.

Right now it is seeing a rapid adoption of metal tiles owing to the perfect fit it makes with the very typical conditions. The tropical weather sees huge swing in temperature and humidity, which leaves the traditional material highly vulnerable reducing its life and aesthetic functionality.There is an option of surface coatings for different functional & aesthetic needs with a choice of two finishes, polyester powder coating and epoxy pre-coating in a range of colours.

Specifications Rectangular or Square shape 600mm x 600mm module Thickness: Aluminum: 0.6mm Galvanized Steel: 0.5mm Exposed T Grid System (Lay-in) in 24mm and 15mm T Grids Concealed Grid System (Clip-in)‘V‘ profile.

Related Project

Full Auto Metal Ceiling Tile Machine Shipping To Italy

Semi Auto Aluminum Ceiling Tile Machine Shipping To India

Installation Service

In order to help our customers to solve machine installation problems, KINGREAL will provide both online and local installation services.

1. Online installation Guide

- Photos and videos of machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting

2. Local installation

KINGREAL will arrange engineers to go abroad to install the machine at the customer place to ensure the normal operation of the machine, and will provide all technical guidance. Exact costs to be negotiated.

FAQ

1. Are you a manufacturer?

Yes, KINGREAL Machinery is a professional sheet metal processing machines manufacturer, we are an OEM. KINGREAL have been focusing on the field of machine manufacturing for more than 20 years.

2. How to visit your factory?

There are 2 ways: either by plane or by train to Foshan/Guangzhou port. We will be picking you up in plane/train station, then we can go together.

3. What's your Warranty ?

12 months except human error, during which all parts damaged because of quality problem will be changed for free. Parts that are out of warranty will be provided in factory price.

4. What's your delivery Time ?

Within 60-80 days after receiving prepayment. Some machines in stock, can be delivered at any time.

5. What's your payment terms ?

40% deposit is paid before production, the balance paid after inspection confirmation before shipment.