Quality Inspection of KINGREAL's strut channel machine

2025-02-09 12:00KINGREAL is committed to providing high-performance machines that meet the highest industry standards. This article will provide an in-depth look at the quality inspection process of the strut channel machine in KINGREAL factory, covering key stages such as machine assembly, commissioning, fine-tuning and multi-size production testing.

Machine assembly: Integrating key components into a complete production line

The first step in ensuring the quality of a machine begins with its assembly process. The unistrut roll forming machine is not a single piece of equipment, but a complete production line consisting of several key components, including:

2-in-1 decoiler and straightener

Responsible for uncoiling and flattening the metal sheet to ensure smooth feeding into the forming system.

Punching machine

Used to punch holes in the metal profile according to specific strut channel requirements.

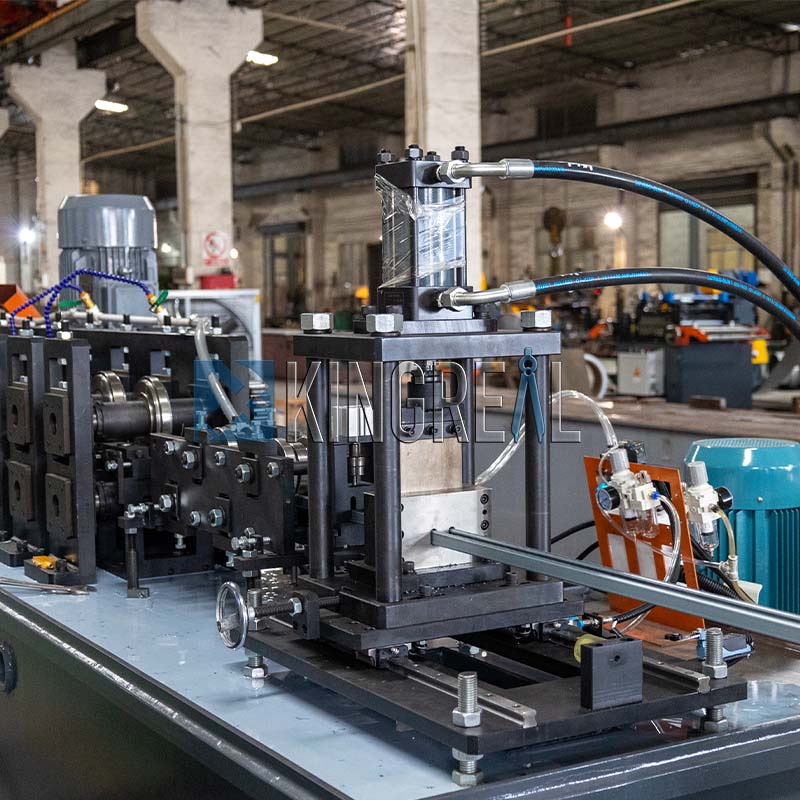

Main roll forming machine

The core unit where the metal strip passes through multiple rollers to achieve the desired channel shape in a precise manner.

Cutting Station

Equipped with high-precision cutting tools, it ensures clean, accurate cuts according to the specified product length.

Auto packaging machine

Automates the final packaging of finished products, improving the efficiency of post-production processing.

Machine Commissioning: Verifying Operational Stability

Once assembly is complete, the next stage is the pv bracket roll forming machine Commissioning, which tests the entire line under actual operating conditions. This is a critical step to detect any potential issues before the pv bracket roll forming machine is shipped to the customer.

Key Aspects of Commissioning

● Full Line Synchronization: The entire line from decoiler to packaging machine is started simultaneously to ensure that all components work in harmony.

● Monitoring Performance: Engineers closely monitor the speed, material flow, and output quality of the machine during the commissioning. Any abnormal vibration, noise, or operational delay is immediately flagged for review.

● Packaging Machine Functionality: The packaging machine requires special attention as it must operate smoothly to avoid bottlenecks at the end of the line. The team checks whether the final products are stacked, strapped, and packaged correctly to ensure that they meet packaging standards.

Machine Adjustment: Fine-Tuning for Optimal Performance

No machine is perfect once assembled, which is why fine-tuning (or commissioning) is essential. Based on the data collected during the commissioning, KINGREAL engineers adjust various machine parameters to optimize performance.

Production Testing: Validating Capabilities for Multiple pv bracket Sizes

The final stage of quality inspection involves production testing, where the photovoltaic support roll forming machine’s ability to manufacture different strut channel structures is evaluated. For KINGREAL’s strut channel machine, the focus is on producing two sizes: 41 x 21 mm and 41 x 41 mm.

Switching from producing 41x21 mm to 41 x 41 mm requires replacing the hanging bracket (hanging device) within the strut channel machine. The size changeover process is fast, effectively improving the efficiency of the unistrut roll forming machine in switching between production runs, which is critical for factories handling multiple product lines.