Saudi Arabian Customer Visit -- false ceiling channel machine

2025-01-06 16:04Initial contact with the customer

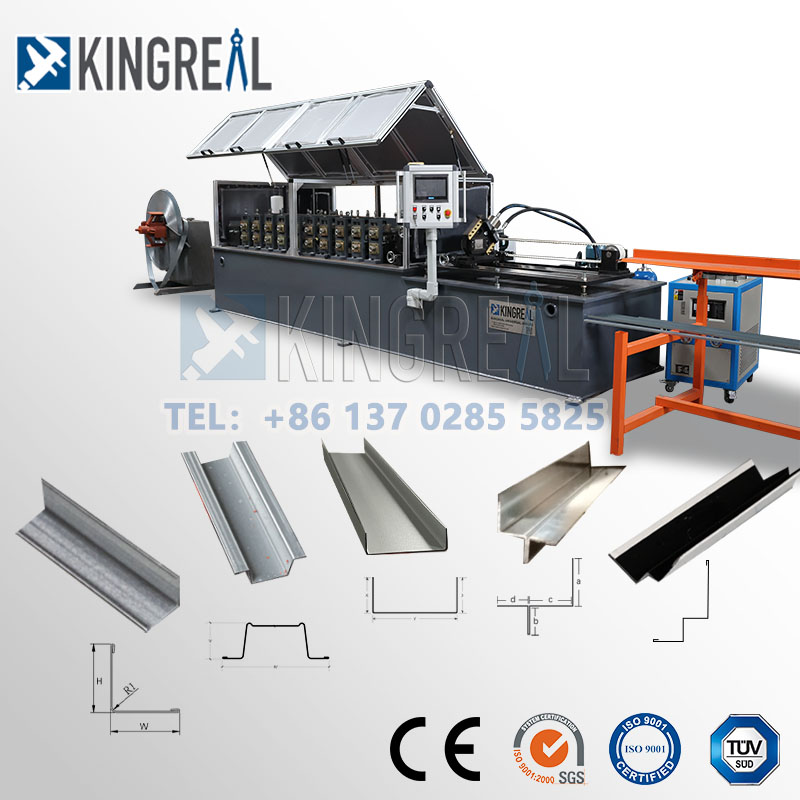

A customer in Saudi Arabia learned from a friend that KINGREAL is a professional metal processing equipment manufacturer, and is famous for its high-quality machines and excellent services. The customer hopes to purchase a false ceiling channel machine to improve the production efficiency and product quality of his company.

KINGREAL staff conducted preliminary demand communication with the Saudi customer through the Internet, and learned about the customer's production scenario, demand focus, and specific expectations for the equipment. In order to let the customer have a more comprehensive understanding of KINGREAL's products and strengths, the staff invited the customer to visit the factory. The customer gladly accepted the invitation and looks forward to further understanding the performance of the machine through field visits.

Customer factory visit

KINGREAL sent a special person to the airport to receive the Saudi customer, which reflects the high attention and warm welcome to the customer. When the customer arrived at the factory, the KINGREAL team arranged a detailed tour for the customer to fully demonstrate the company's strength and equipment performance.

1. Factory strength display

- Manufacturing workshop: The customer visited KINGREAL's manufacturing workshop and learned about the company's production scale, modern equipment and strict quality management system.

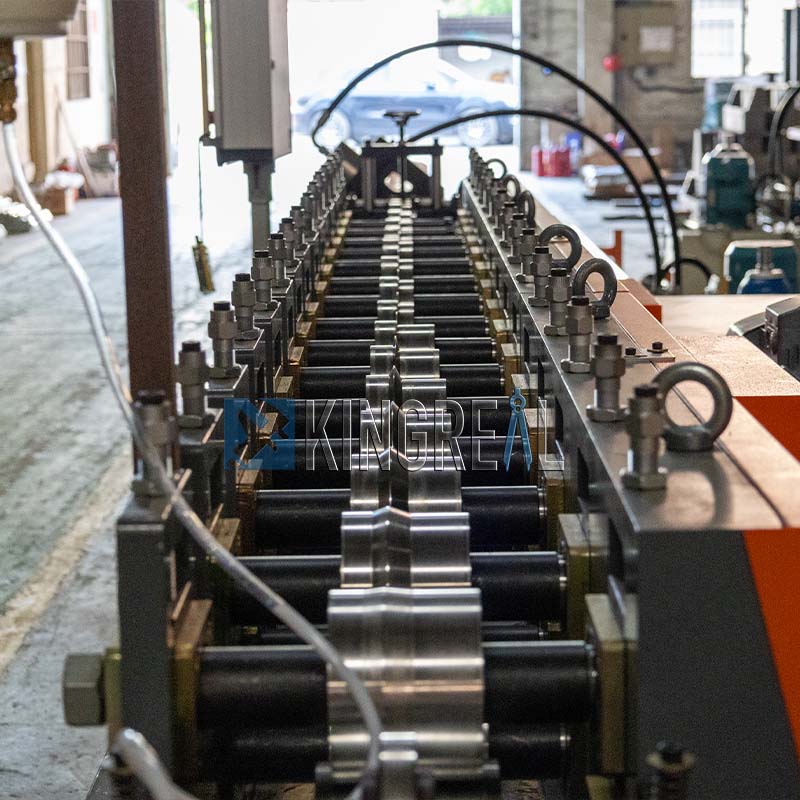

- Test workshop: Customers were taken to the u shape profile roll forming machine test workshop to observe the operation of the equipment in a real production environment.

- Finished product storage room: The staff displayed various completed false ceiling channel machines and customized products, allowing customers to intuitively experience KINGREAL's diverse production capabilities.

2. Detailed explanation of the u shape profile roll forming machine

In the false ceiling channel machine test workshop, the staff introduced the structure and working principle of the machine in detail:

- Components: The false ceiling channel machine consists of modules such as decoiler, main roll forming machine, flying shear station, discharge table, electrical system and hydraulic system. All components are selected from well-known brands to ensure quality.

- Technical details: KINGREAL u shape profile roll forming machine production speed can reach 120m/min, which is suitable for efficient mass production.

3. Customer questions and answers

During the visit, the customer raised several technical questions:

- Production speed: The customer is concerned about whether the u shape profile roll forming machine's production capacity can meet its needs. The staff explained that the maximum production speed of the machine is 120m/min, which is suitable for efficient mass production.

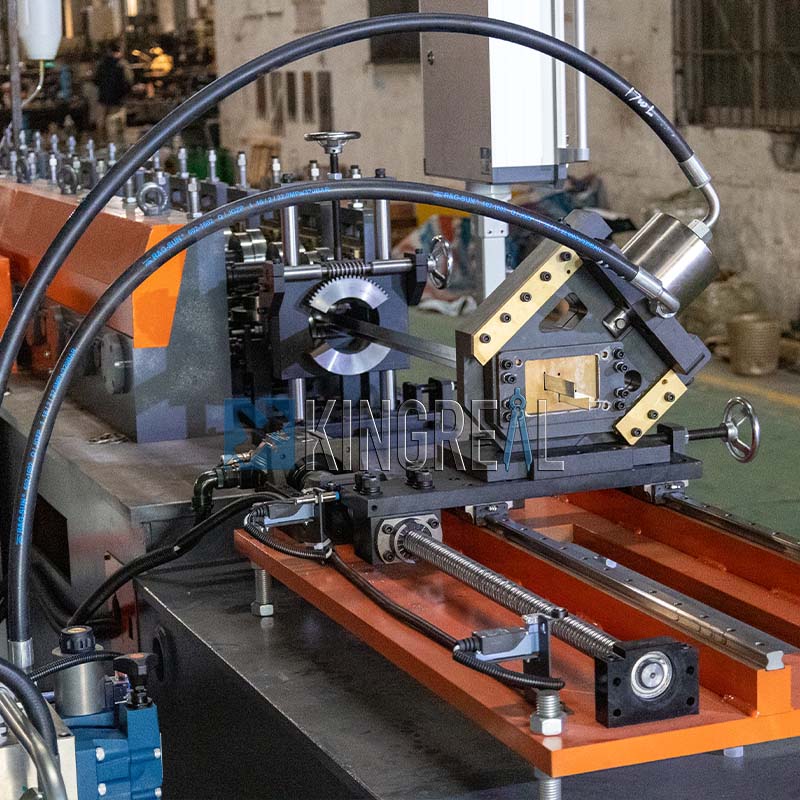

- Service life and cleaning and maintenance: The customer asked how to extend the life of the equipment. The staff introduced the function of the protective shield, which not only protects the safety of workers, but also reduces the damage to the equipment by dust and debris. The staff also emphasized that the protective cover can effectively keep the equipment and workshop clean and reduce maintenance costs.

The customer highly recognized the professional answers of the staff and the efficient performance of the false ceiling channel machine, and reached a preliminary cooperation intention with KINGREAL on the spot after the visit.

Core advantages of KINGREAL u shape profile roll forming machine

1. Automatic width adjustment

KINGREAL u shape profile roll forming machine has the function of automatic width adjustment. Users only need to set the size on the touch screen, and the equipment can be adjusted accurately, greatly improving production flexibility and efficiency.

2. Double-head decoiler

The double-head decoiler design can process two rolls of material at the same time, reduce the time of changing rolls, realize uninterrupted material supply, and significantly improve the overall production efficiency.

3. Multiple shearing modes

- Fly shearing: suitable for high-speed continuous production.

- Follow shearing: taking into account both efficiency and accuracy.

- Stop shearing: used for precise shearing for special needs.

Customers can choose the most suitable shearing mode according to actual production needs.

4. 3-in-1 false ceiling channel machine

The 3-in-1 false ceiling channel machine provided by KINGREAL can produce three different styles of products: L-shaped, U-shaped and cap-shaped. Customers only need to replace the rollers and cutting molds to meet the production needs of different products, which greatly saves equipment costs and space.

5. Automatic packaging machine

In order to achieve fully automated production, KINGREAL can also equip customers with automatic packaging machine. After the product is manufactured from the u shape profile roll forming machine, it directly enters the baler for automatic packaging without manual intervention, which saves labor costs and improves production efficiency.