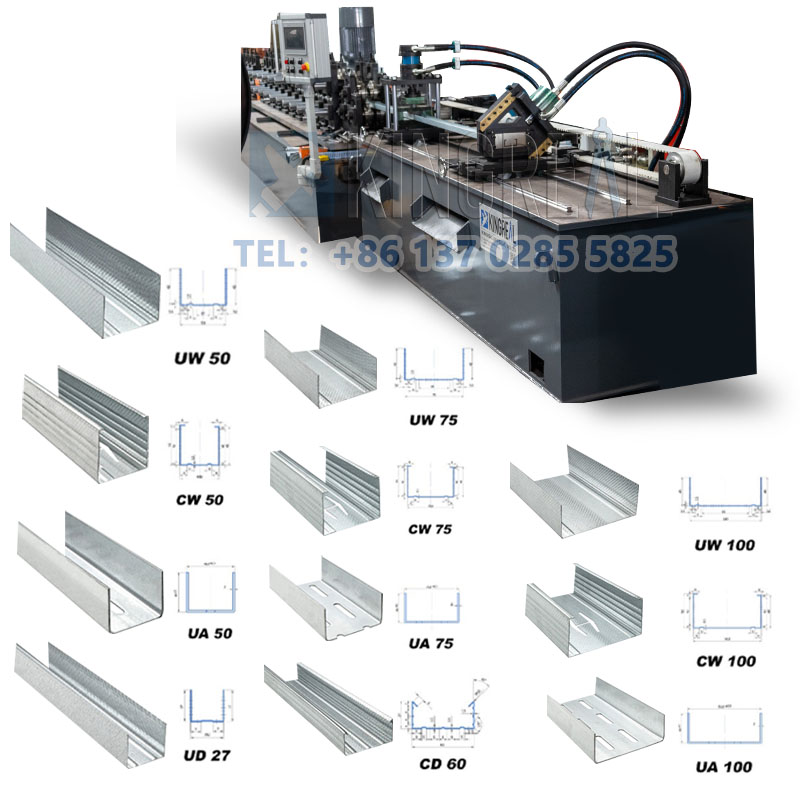

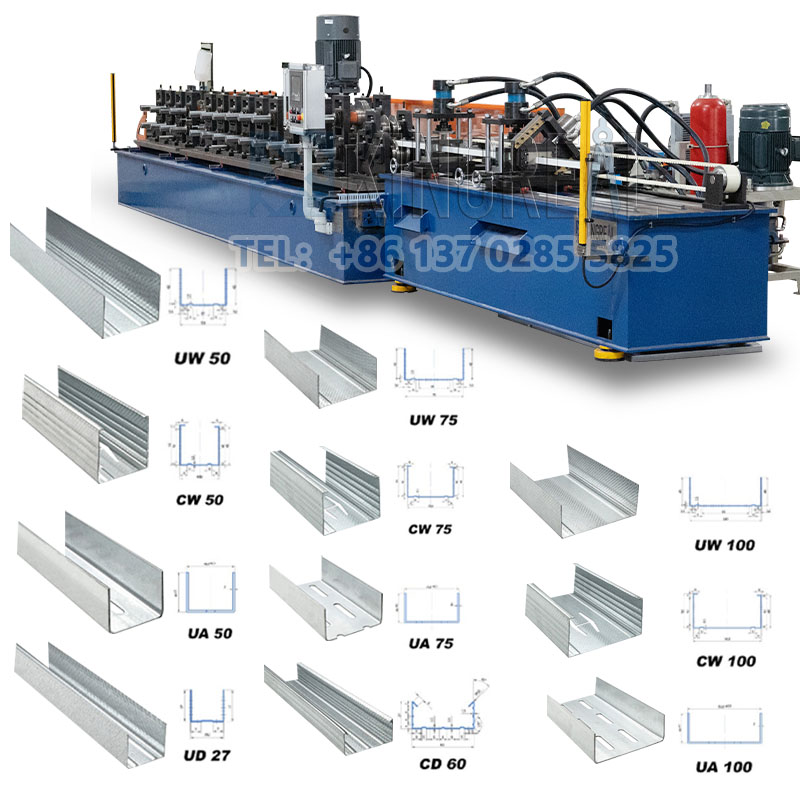

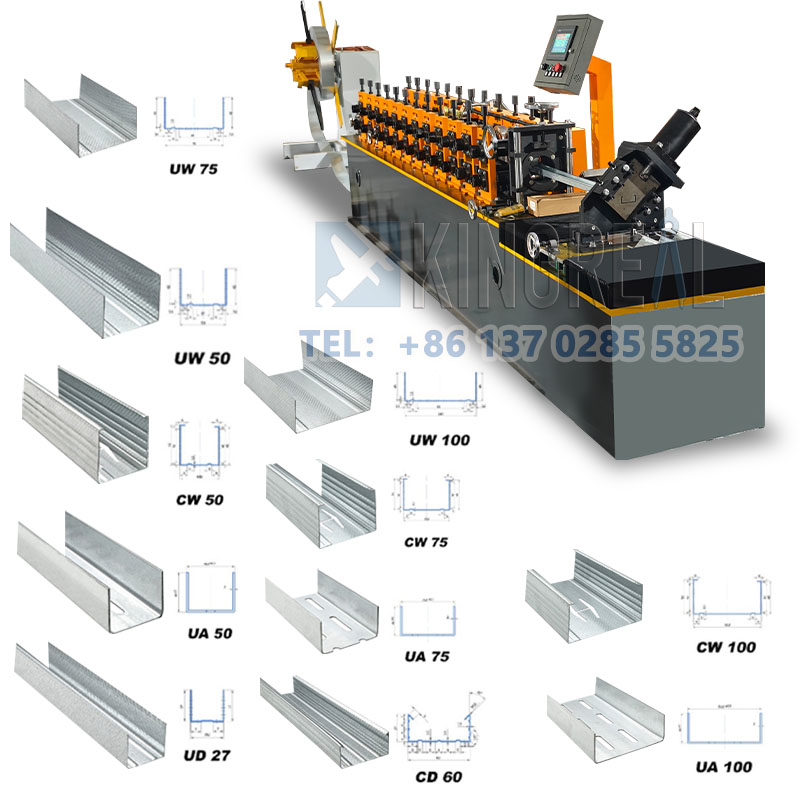

Case -- Metal Stud and Track Machine

2025-03-20 12:01Metal stud and track machine is a featured machine of KINGREAL. It has been sold to many countries, including Canada, Russia, Saudi Arabia, Turkey, Brazil, India, UAE, Chile, Egypt, etc., and maintains close contact and friendly cooperation with customers in many countries. The steel stud and track machine not only improves production efficiency, but also meets the special needs of different markets through customized design. In this article, KINGREAL will discuss in detail the application cases of drywall profile machines in different countries and the innovative solutions they bring.

Drywall Profile Machine in Canada

In Canada, due to high labor costs, many factories are facing the problem of high labor costs. A customer who had cooperated with KINGREAL mentioned in a return visit that he needed to equip the production of drywall profiles with multiple workers to carry out bundling, packaging and stacking. In order to help customers reduce labor costs, KINGREAL engineers proposed an innovative solution: equip the steel stud and track machine with an automatic packaging machine.

This design greatly improves production efficiency. After the stud and track is produced, it can be automatically transported to the packaging machine for fully automated bundling and stacking. The strapping is tied very tightly to ensure that it will not loosen during transportation, causing the product to scatter. Canadian customers reported the success of this solution after just two days of production, saying that the automated design of the drywall profile machine not only saves labor costs, but also improves overall work efficiency. The steel stud and track machine remains efficient after working for a long time and will not reduce production speed due to fatigue.

This innovative automatic packaging solution has achieved remarkable success in the Canadian market and attracted the attention of more customers. KINGREAL continues to optimize equipment through close cooperation with customers to ensure that its products are competitive in the market.

Drywall Profile Machine in Russia

The Russian market has a special demand for steel stud and track machines, which is mainly reflected in the thickness of metal raw materials. Compared with other countries, Russian customers generally need to handle a larger thickness of metal. When a customer contacted KINGREAL, he clearly stated that he hoped to design a heavy-duty drywall profile machine that meets his needs and can handle metal materials with a thickness of up to 1.2mm.

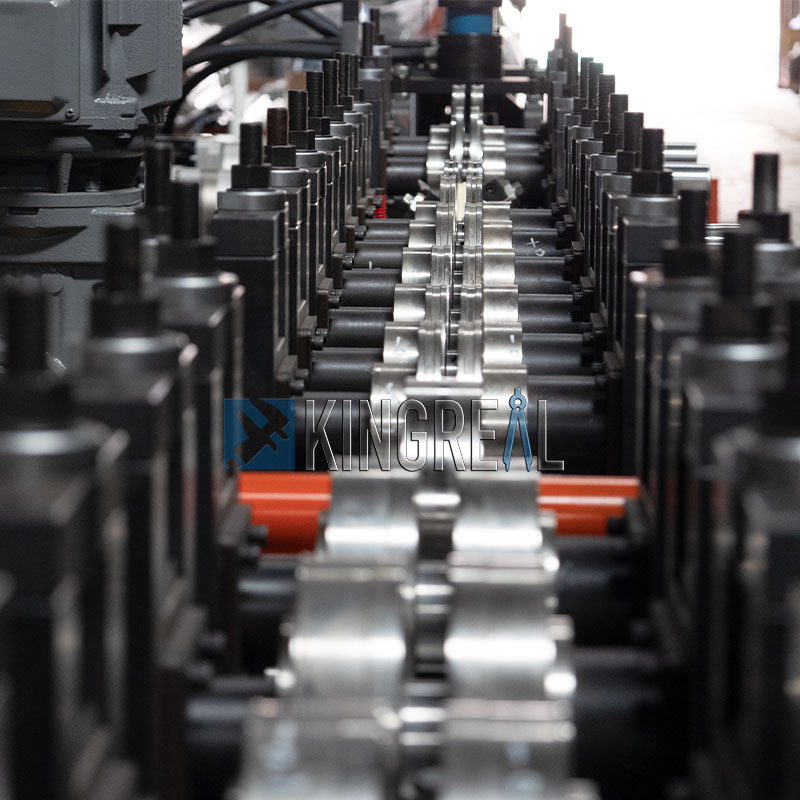

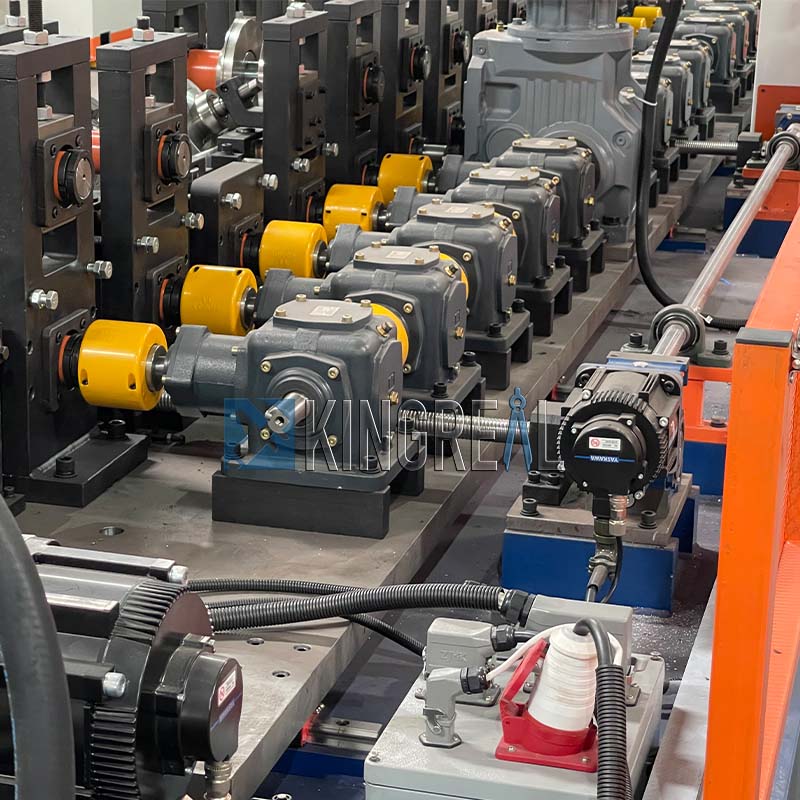

After receiving the customer's needs, KINGREAL engineers conducted full communication and combined the market characteristics of Russia and the drawings provided by the customer to finally design a heavy-duty drywall profile machine. This steel stud and track machine can not only process metal materials with a thickness of 0.8-1.2mm, but also increase the maximum production speed to 80 m/min. In order to improve production efficiency, the drywall profile machine is also equipped with a flying shear system, which can cut according to the customer's preset length and does not require stopping during the shearing process.

This customized design not only meets the production needs of Russian customers, but also improves the overall production efficiency, showing KINGREAL's continuous innovation and progress in technology.

Steel Stud and Track Machine in Saudi Arabia

The special climatic conditions in Saudi Arabia pose challenges to the use of mechanical equipment. The average daily maximum temperature in summer can reach 38°C. Standard drywall profile machines are prone to failure in such an environment. Therefore, KINGREAL conducted in-depth research on this issue and equipped the motor of the drywall profile machine with cooling equipment to ensure the normal operation of the machine in a high temperature environment.

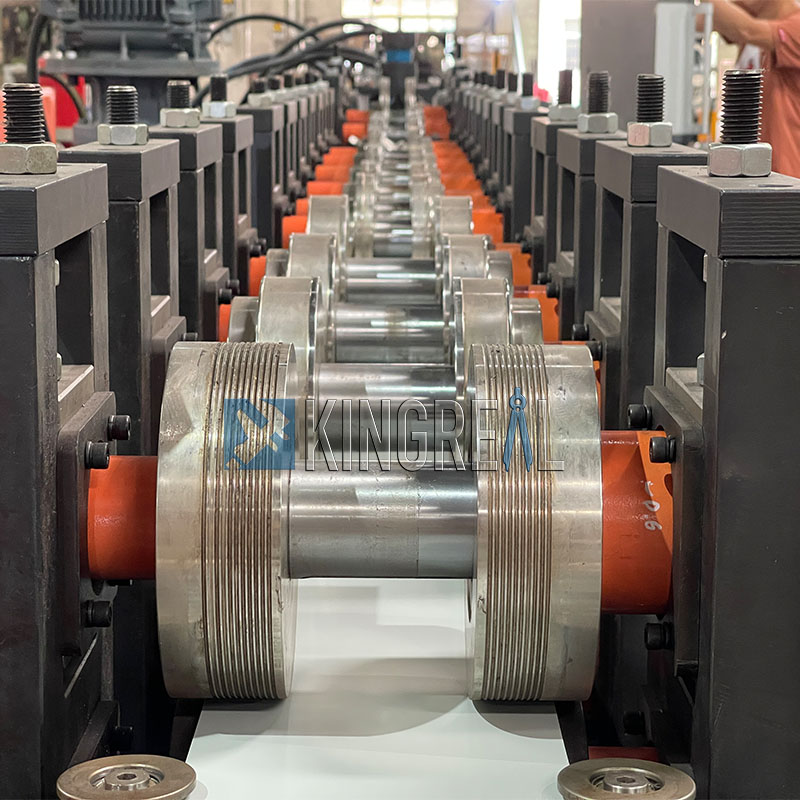

In addition to adding cooling equipment to the motor, KINGREAL also made no compromises on other configurations of the steel stud and track machine, and still used high-quality Cr12 Mov materials to make forming rollers to ensure that the machine is durable and has good forming effects. In terms of electrical appliance brands, KINGREAL insists on using well-known brands to improve the reliability and stability of the drywall profile machine.

Through these designs, KINGREAL's drywall profile machine has been highly recognized by customers in the Saudi Arabian market. It can operate stably in extreme climates, ensure production efficiency, and not reduce production capacity due to climate reasons.

Steel Stud and Track Machine in Turkey

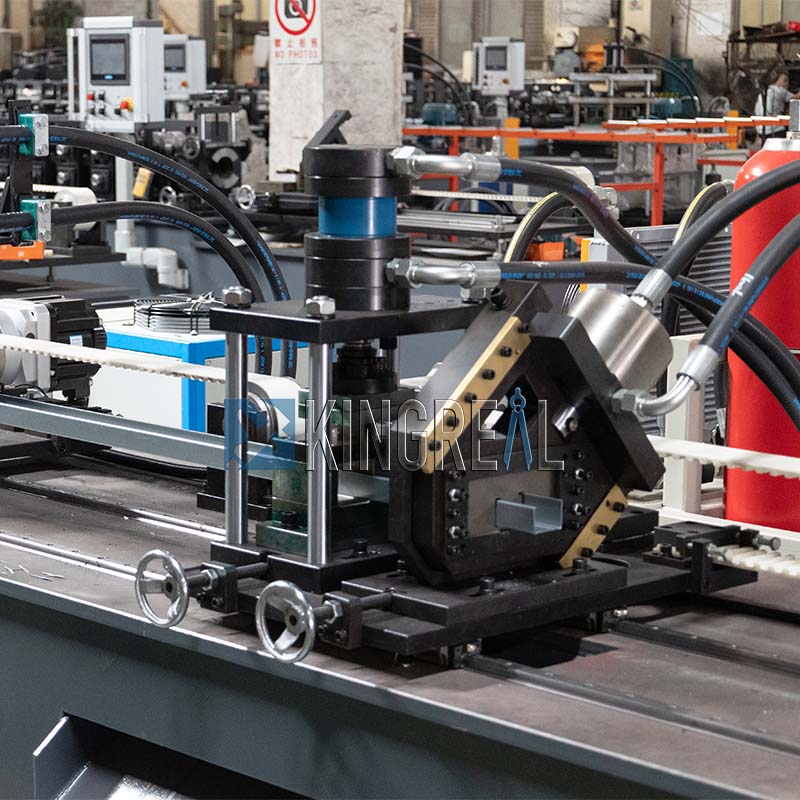

Turkish customers attach great importance to the safety of the drywall profile machine, especially in terms of worker safety. In order to ensure that workers can be safe and worry-free during operation, KINGREAL fully communicated with Turkish customers and designed a steel stud and track machine with a protective shield. The entire main roll forming machine is wrapped in a protective shield, which significantly reduces the risk of workers being injured at work.

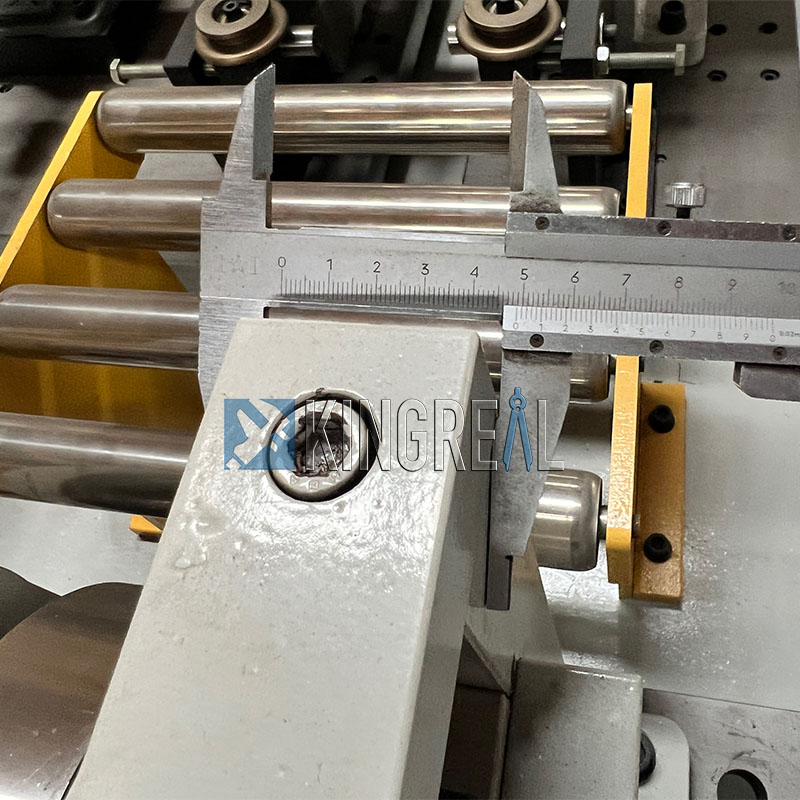

In addition, the design with a protective shield also helps to keep the factory workshop clean and tidy and prevent metal sheets from splashing everywhere during the production process. After the drywall profile machinewas manufactured, KINGREAL engineers conducted rigorous testing on the steel stud and track machine, including careful measurement of the length, width and height of each component to ensure that it met the commitments in the design plan. At the same time, it was also tested whether the machine can produce high-precision 60x27mm CD profiles and 28x27mm UD profiles.

After all the tests were passed, KINGREAL staff accurately packaged the various components of the drywall profile machine and sent them to the Turkish customer's factory smoothly. The successful implementation of this safety design not only won the trust of customers, but also established a good reputation for KINGREAL in the international market.

Drywall Profile Machine in India

In the Indian market, there are many suppliers of drywall profiles, and the competition among major manufacturers is extremely fierce. For this reason, how to improve the market competitiveness of metal stud and track has become an important topic for every manufacturer. After in-depth market research, KINGREAL engineers keenly grasped this point and decided to equip the drywall profile machine with inkject coding to enhance the personalization and customization of the product.

Through the inkjet coding, Indian customers can spray their own logo or other required text on the steel stud and track during the production process, thereby realizing the customization of the product. This not only increases the added value of the product, but also enhances the brand recognition, making customers more competitive in the market.

This innovative measure has received a good response in the Indian market. Customers have said that the equipment of the inkjet coding has made their products more competitive in the market and also improved their brand image.

Packing & Delivery Service