Metal Perforated Machine

KINGREAL Metal Perforated Production Line is used for producing different kinds of perforated metal sheet panel, raw material can be stainless steel, alloy aluminum and glavanized steel. Metal Perforated Production Line can be custom-designed and manufactured according to customer requirements.

1. Advantages of KINGREAL metal perforated machine

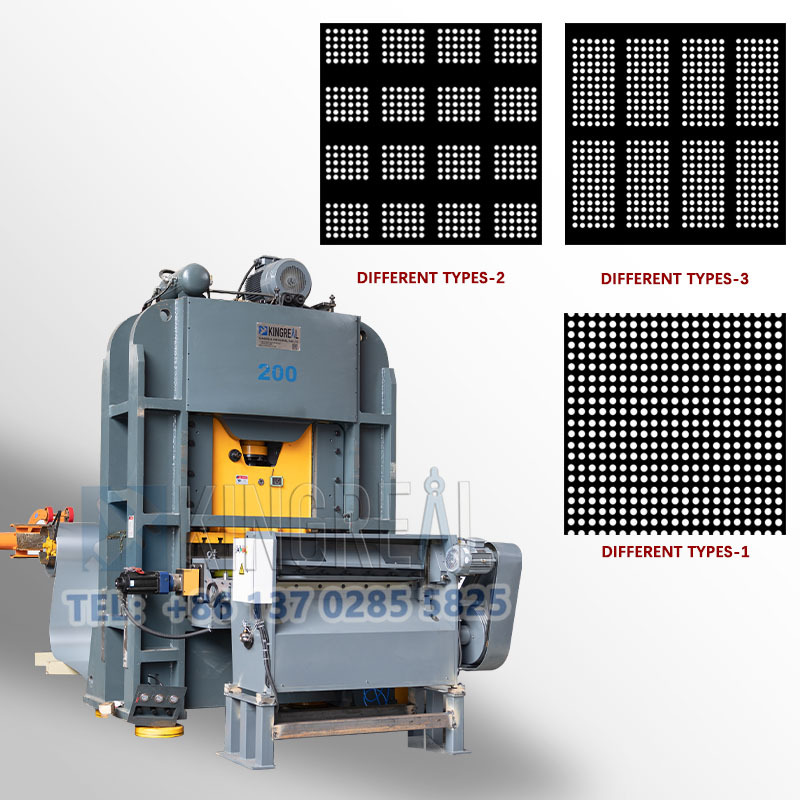

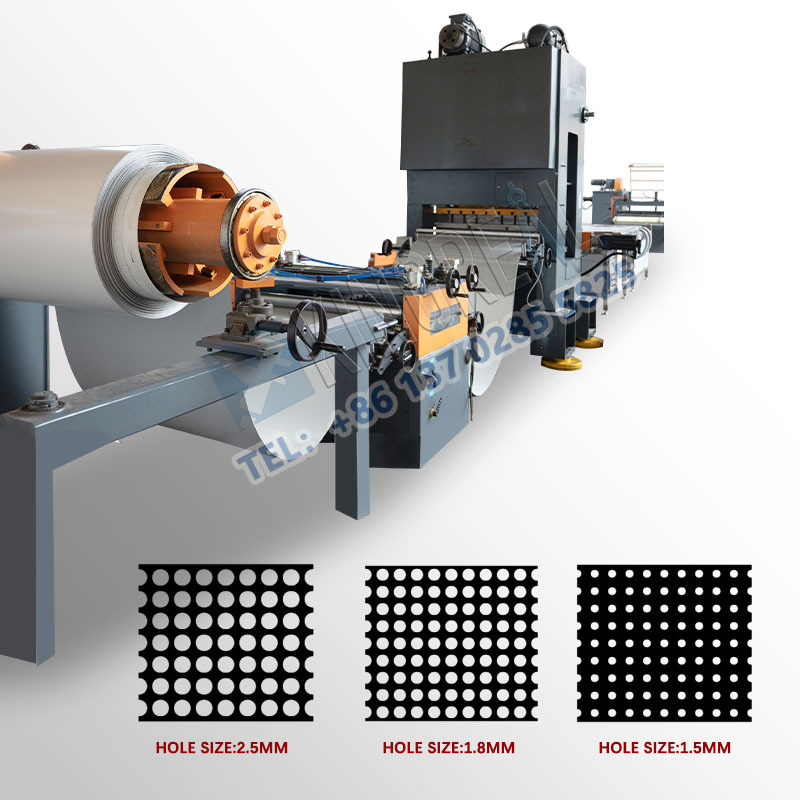

Metal sheet perforation line is composed of decoiler, precision straightener, punching machine and other precision parts. It can process various shapes of holes on the surface of metal sheets with different materials (such as aluminum, galvanized steel and stainless steel) to make perforated sheets. KINGREAL can provide customers with metal sheet perforation line solutions to meet different metal punching needs. Whether it is raw material punching, semi-finished product (such as metal sheet) punching or finished product punching (such as metal ceiling), it can be easily achieved here at KINGREAL.

KINGREAL strictly controls the manufacturing of coil to coil perforated making machines. The metal sheet perforation machines used are from the well-known brand Yangli, and the cutting station is equipped with high-hardness, high-quality material blades. The punching molds are completely customized according to the customer's drawings. It is these factors that ensure high-speed and high-precision punching, significantly reduce manual intervention, and greatly improve production efficiency.

At present, KINGREAL's metal perforation line has been sold to Brazil, India, Turkey, Russia, Saudi Arabia, Greece and other countries. If you are in need of metal perforated machine, please feel free to contact us, whether you want to know more about product performance details or discuss personalized customization schemes!

2. KINGREAL provides customized coil perforation line

KINGREAL knows that each customer has unique needs, so it makes every effort to tailor a highly customized coil perforation line solution for customers. Our team will make a suitable punching die according to the drawings provided by customers, and give reasonable suggestions on the tonnage of punching machines in combination with the production scale, sheet material and expected output of customers.

In terms of production line configuration, KINGREAL will customize the corresponding solutions according to the different application scenarios of customers for perforated sheets. If customers need to quickly cut the sheet to a suitable size after punching, we will equip them with an efficient cutting station to build a coil to coil perforated making machine with cutting; If customers have the demand of continuous production and winding, we will provide a coil to coil perforated making machine equipped with a recoiler; For metal ceiling manufacturers, we can customize the metal ceiling perforation line that can cooperate with the metal ceiling machine.

Not only that, if customers have personalized needs, such as equipped with metal sheet washing machines, KINGREAL can fully meet them, ensuring to provide every customer with the most suitable coil perforation line solution.

3. KINGREAL provides one-stop service

From the moment customers demand the metal sheet perforation line, KINGREAL will accompany them all the time.

Taking the coil perforation line with rewinding that cooperated with Brazilian customers in 2024 as an example, in the early stage, KINGREAL warmly invited Brazilian customers to the KINGREAL factory for a field visit to learn more about the operation of the coil to coil perforated making machine. Then, after the customer had a deeper understanding of the KINGREAL metal sheet perforation line, KINGREAL engineers communicated with Brazilian customers in detail in the conference room about the manufacturing plan of the metal perforated machine. KINGREAL engineers deeply explored customer needs.

After learning that the customer would experience a long period of transportation after the perforated sheet was completed, they proposed to equip the customer's metal perforation line with an automatic recoiler to better protect the metal surface and facilitate long-distance transportation. During the manufacturing process of the coil perforation line, KINGREAL understood the Brazilian customer's curiosity about the progress of the project, maintained communication with the customer, and reported the latest progress to the customer after the manufacturing of each component was completed.

After the metal sheet perforation line was manufactured, KINGREAL staff conducted a series of rigorous machine tests on the machine to ensure that the coil to coil perforated making machine could reach the production speed required by Brazilian customers, and could produce burr-free and high-precision perforated sheets, and then each component of the metal perforation line was tightly packaged and shipped.

After the metal perforated machine arrived at the Brazilian customer's factory, KINGREAL also sent professional engineers to install it offline and provided training on the operation of the coil to coil perforated making machine for the employees of the Brazilian customer's factory, including debugging the punching mold, how to start and shut down the coil perforation line, etc.

4. Application of coil to coil perforated making machine

The demand for metal perforated machines in the market continues to grow, reflecting its importance and wide application in various industries. The flexibility and efficiency of coil to coil perforated making machines enable them to meet the special needs of different fields. The following are common application scenarios classified by application field:

(1)Architectural field

Perforated wall panels: used to create beautiful and practical building appearance, improve the ventilation and lighting effects of buildings.

Perforated ceilings: improve indoor acoustic performance while enhancing visual effects.

Perforated balcony guardrails: while ensuring safety, they are also decorative and enhance the beauty of buildings.

(2)Transportation field

Highway sound-absorbing panels: effectively reduce traffic noise, improve driving comfort, and promote environmental protection.

(3)Household items

Perforated metal chairs: unique design, both beautiful and practical, suitable for various indoor and outdoor environments.

Perforated baking trays: improve cooking results and make food more delicious.

(4)Industrial applications

Perforated silencers: reduce noise in a variety of industrial environments and protect the quietness of the workplace.

Perforated filters: effectively filter impurities and ensure the purity of fluids.

Perforated screen: widely used in mining and construction, providing efficient screening solutions.

Perforated ventilation and heat dissipation plate: optimize equipment heat dissipation, improve work efficiency, and extend equipment service life.