Metal Perforated Production Line

KINGREAL Metal Perforated Production Line is used for producing different kinds of perforated metal sheet panel, raw material can be stainless steel, alloy aluminum and glavanized steel. Metal Perforated Production Line can be custom-designed and manufactured according to customer requirements。

- KINGREAL

- China

- 80 Days

- 999

- Information

- Download

Video Dislpay Of Metal Perforating Machine

Sheet Metal Perforating Machine Description

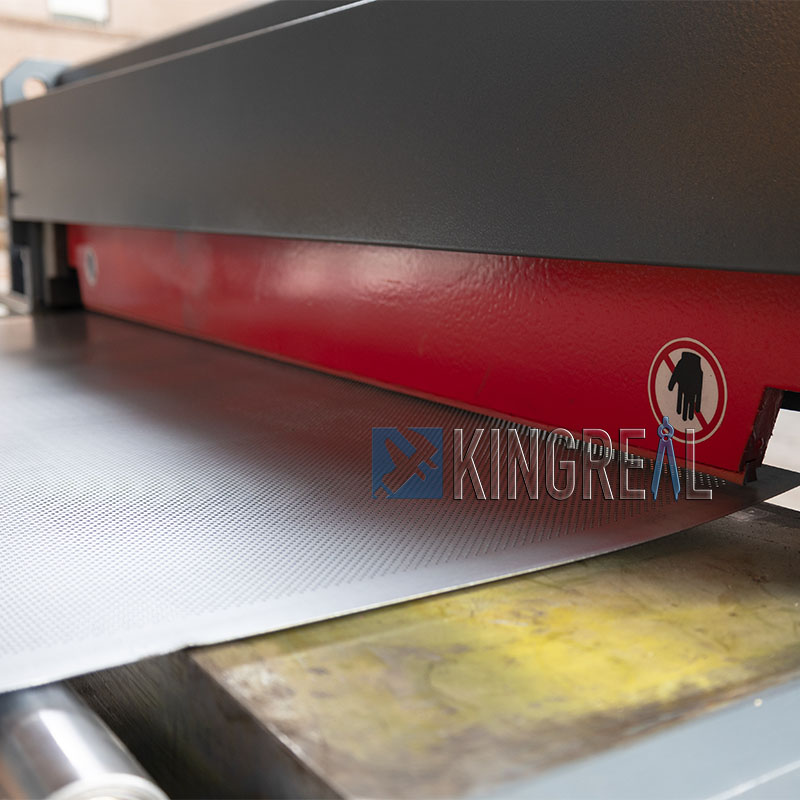

KINGREAL Perforated Metal Machine is used for producing different kinds of perforated metal sheet panel, raw material can be stainless steel, alloy aluminum and glavanized steel. The sheet metal perforating machine feed material can be coil or cutted steel material.

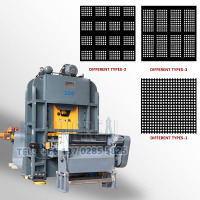

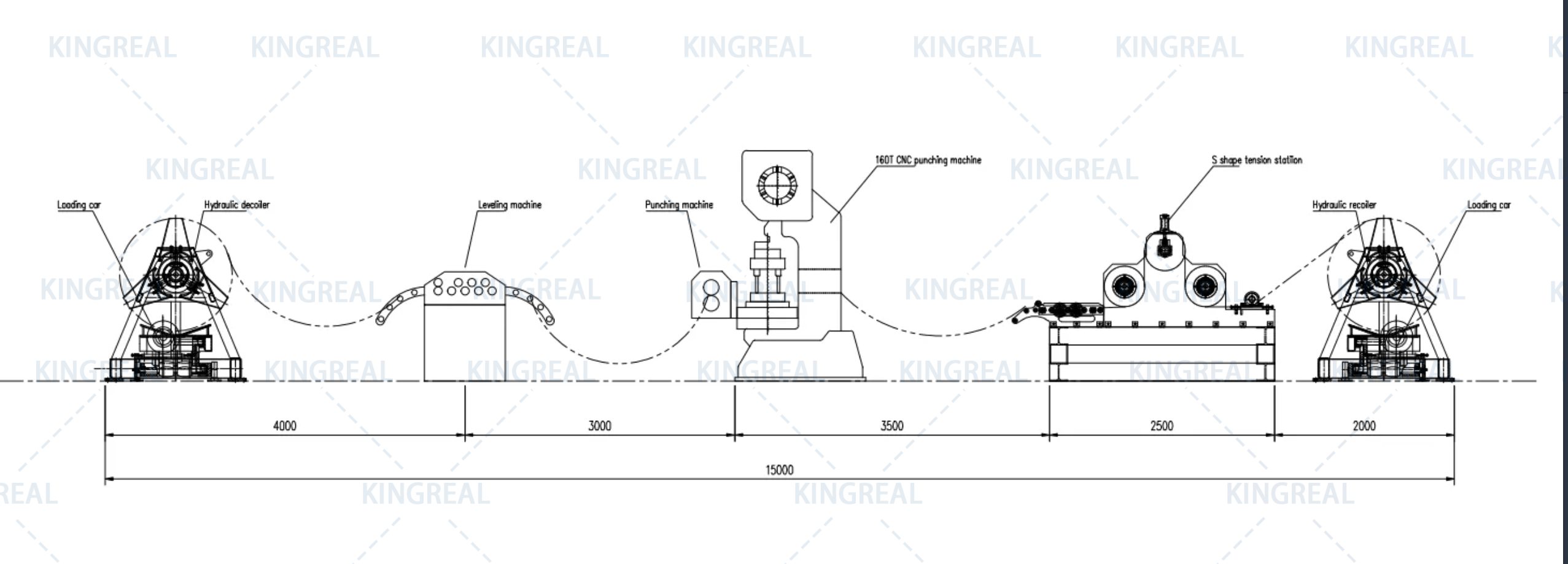

Main structure of the metal perforation panel can be designed as customers‘ requirements. The raw material can be coil or cutted steel piece.Basic procedure of the sheet metal perforating machine is uncoiler, servo feeding, gantry press holes punch, then recoil the material. Also KINGREAL can change the dies of the gantry press to produce different type of the perforated panel.

Technical Specification Of Perforated Metal Machine

| Thickness of material | Galvanised metal sheet/Prepainted sheet metal |

| Inner diameter | Φ 500 |

| Outer diameter | Φ 1200 |

| Maximum load | 5 tons |

| Expansion | Hydraulic expansion |

| Speed reducer | Cycloid pin |

| Speed adjustment | Adjusted by transducer |

| Electric motor | 3 KW |

Working Process Of Sheet Metal Perforating Machine

Raw Material Uncoil → Pre Straightener → 125 Ton Gantry Press Perforation holes→ Servo Feeding → Hydraulic Shearing Machine

Advantage Of Sheet Metal Perforating Machine

1. Metal Punching Machine can save labors cost when the market get bigger and bigger. 2. Sheet Metal Punching Machine will save time of cool and drying. 3. KINGREAL have the rich production experience. KINGREAL perforated metal machine had already been exported to Dubai, Turkey and etc, Which had proved to be high quality, high efficiency. It is best choice for the aluminum ceiling tile manufacturers and construction supplier factory. |  |

Features Of Perforated Metal Machine

✦ Can punch holes in different metal materials ✦ Can punch out different holes ✦ Customized metal punching machine manufacturing solutions for customers ✦ Fast punching speed |  |

Components Of Metal Perforating Machine

KINGREAL's perforated metal machine is composed of multiple precision parts such as decoiler, cutting station, punching die, etc., which ensures the efficiency and accuracy of the entire production process. KINGREAL has a rigorous and experienced perforated sheet metal punching machine manufacturing team. Engineers strictly control every detail, even as small as a screw, and require it to be perfectly matched with the perforated metal machine, rather than just muddling through. This spirit of pursuit of excellence is reflected in every manufacturing link. It is this attitude of striving for excellence that makes KINGREAL's sheet metal punching machine win high praise and trust from customers in the industry.

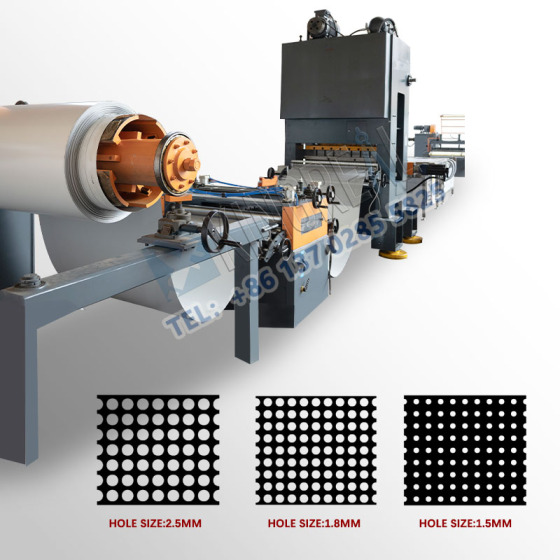

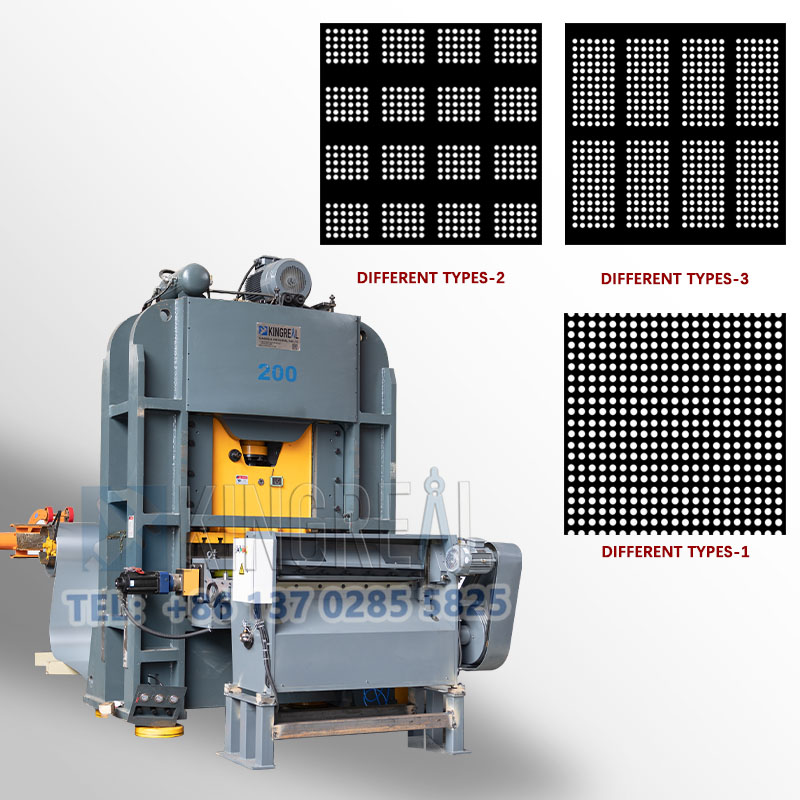

Different Hole Type As You Need

- Round hole perforated - Square hole perforated - Slotted hole perforated - Hexagonal ( honeycomb ) perforated - Ornamental& decorative perforated |  |

Application Areas Of Perforated Metal

The most common field of use for perforated metal is the construction industry. As we know, the perforated metals have been used in architecture for hundreds of years. Such as the perforated metal ceiling tile can not only increase the aesthetic value of the building but also absorb noise, which is deeply loved by consumers.

In addition, based on the characteristics of punched metal, it is also made into different shapes and widely used in food production, retail display and used to control the noise.

Technical Team In Brazil

KINGREAL engineers have traveled to Brazil to provide professional sheet metal punching machine installation services for customers. During the installation process, first, the engineers will carefully open the tight machine packaging and check each component of sheet metal punching machine with local workers to ensure that it has not been damaged during transportation. They carefully observe the integrity of the mechanical components, pay special attention to the status of the punching parts, and only after confirming that all parts are intact can they start assembling the production line.

FAQ

1. What‘s your Install and Training ?

If buyers come to KINGREAL factory to inspect, the training to install and operate is provided face to face.

If not, Manual book and video is provided to show how to install and operate.

2. When will you tell me the price?

After confirming all detailed configurations of the sheet metal punching machine line, that KINGREAL is able to make offer for you.

3. How many people will come to install and commission the perforated metal machine?

Usually 1 engineer is enough to do all the things. All his expense during this travel will be paid by buyer accordingly.