Coil To Coil Perforation Line

Coil To Coil Perforated Machine also call metal coil perforation line rewinding machine is used to produce different type and size perforated sheet or coil, which can be used as a raw material for secondary processing in many different fields and industries, such as the construction industry, the electrical appliances industry, machine production and the automotive industry.

- KINGREAL

- China

- 80 Days

- 9999

- Information

- Download

Video About Sheet Metal Blanking Line

Coil To Coil Perforation Line Description

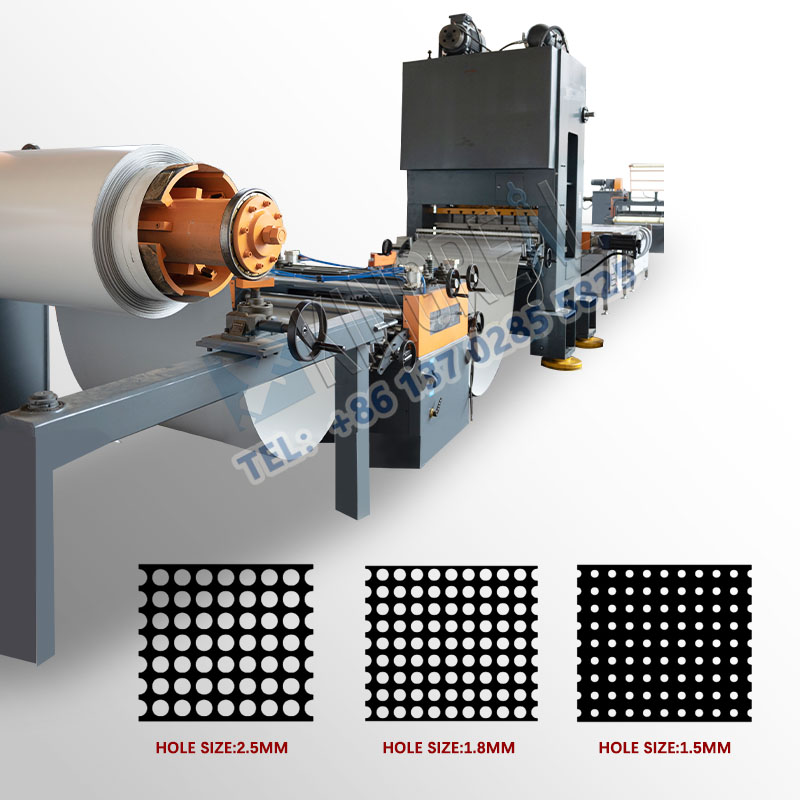

KINGREAL Coil To Coil Perforated Machine also called metal coil perforation line rewinding machine is used to produce different type and size perforated sheet or coil. This metal perforation line can be used as a raw material for secondary processing in many different fields and industries, such as the construction industry, the electrical appliances industry, machine production and the automotive industry.

KINGREAL coil to coil perforation line adopts automatic material input, first flattening, punch press, servo feeding, precision straightener, tension device and recoil. All components of sheet metal blanking line can be custom designed and matched to meet the needs of the customer for metal coil processing. KINGREAL has extensive experience in the field of coil perforation line and has customized many different types of sheet metal blanking lines.

Main Components Details About Coil To Coil Perforation Line

1. Coil Perforated Machine Hydraulic Decoiler

KINGREAL coil perforated machine equipped with hydraulic decoiler. Unwinding and feeding of coils of different materials and weights by means of hydraulic drive. The hydraulic decoiler capacity is 5 Ton and the raw material width is 700mm.

Thickness of material | Galvanised metal sheet Pre-painted sheet metal |

Inner diameter | Φ 500 |

Outer diameter | Φ 1200 |

Maximum load | 5 tons |

Expansion diameter | Φ 450-530 (Φ 508 adaptable) |

Expansion | Hydraulic expansion |

2. Coil Perforation Line High Precision Straightener

KINGREAL coil perforated machine is equipped with straightener. This professional flatting device has nine top rollers and ten bottom rollers to prevent roller deformation. The 58mm diameter roller has simultaneous adjustment for the upper roller. To guarantee the smoothness, durability, and strength of the surface and prevent scratches on the tiles, it is hard-chrome plated.

Width of material | <700 mm |

Thickness of material | 0.3 - 2.2 mm |

Feeding speed | 25m / min |

Electric motor | Three-phase asynchronous motor, 3 KW |

Overall rollers | 19 |

Upper rollers | 9 |

Lower roller | 10 |

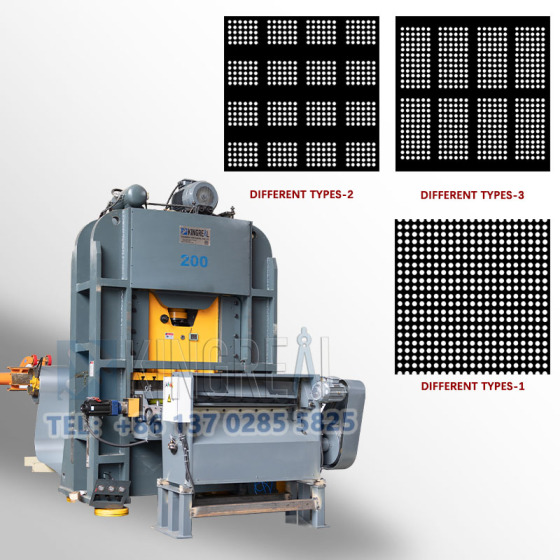

3. Perforated Sheet Punch Press Machine

To punch the hole, KINGREAL employ a 125-ton high-speed gantry press for metal perforation line. Each time, 4–8 rows of holes can be punched. The perforation hole is determined by the customer's design, and the punch speed of sheet metal blanking line can be adjusted between 160 and 220 strokes per minute.

Capacity | 1250kN |

Nominal Stroke | 3mm |

Slide Stroke | 30mm |

SPM | 160-220 |

Max. Die Height | 400mm |

Die Height Adjustment | 50mm |

4. Coil Perforated Machine Rewinding Device

KINGREAL can provide customers with winding devices for metal perforation line to improve the precision of winding raw materials through tension settings, and provide customers with perforated coil products for secondary transportation and processing.

Material inner diameter | ø500 |

Material External Diameter | ø1200 |

Max. Loading | 3 t |

Expanding diamete | 450-530(ø508mm inner diameter material is applicable) |

Hydraulic Decoiler

High Precision Straightener

Punch Press Machine

Recoiler

Advantage About KINGREAL Coil To Coil Perforation Line

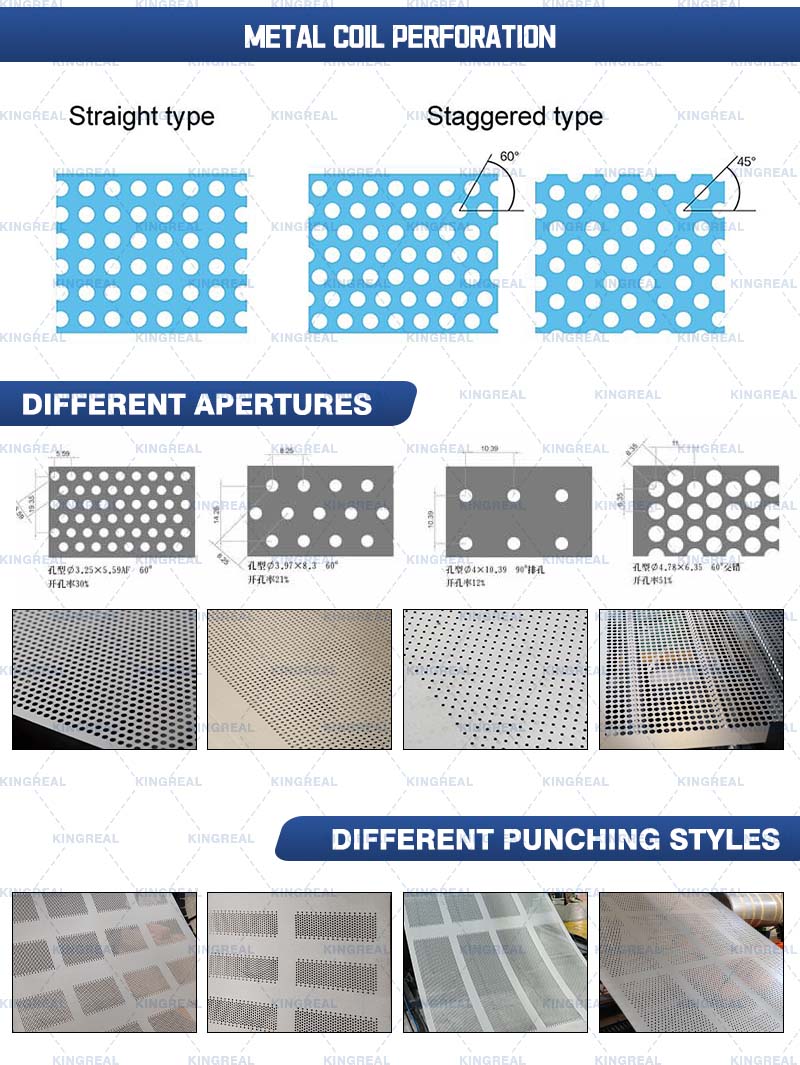

1. Match the processing needs of coils with different thickness and width ranges, such as the common 700MM width, 0.3-1 thickness, and 1.8MM hole spacing. KINGREAL will provide customized Coil To Coil Perforation Line solutions, including a metal perforation line tailoredfor your production needs.

2. Different production speed configurations are available to meet customer's actual production requirements. Metal coil perforated making machine can be configured to achieve production speed variations by adjusting the configuration of the press machine and other additional equipment, KINGREAL high speed press machine can reach 240/SPM.

3. KINGREAL can design and produce punching molds according to customer's drawings for the shape and size of the sheet metal punching pattern, and provide professional technical guidance for calculating the punching tonnage and speed, ensuring optimal performance of the sheet metal blanking line.

4.There are many different types of perforation punching solutions to choose from, including the addition of a hydraulic shearing device to produce the final stack of punched sheet metal and the addition of a cleaning device to clean the surface of the punched coil after punching, such as oil, to meet the high quality of raw materials required by manufacturers who utilize KINGREAL metal coil perforated making machine.

Popular Metal Perforation Line

KINGREAL can provide three types of metal perforation lines, namely coil perforation line with cutting station, metal perforation line with recoiler and metal ceiling coil perforated machine. Customers can choose the appropriate metal perforation line according to actual production needs.

|  |

1. Production Line with Metal Ceiling Perforations This line utilizes the metal coil perforated making machine for the production of perforated metal ceiling tiles or other related panels by the sheet forming or suspended ceiling manufacturer. | 2. Production Line for Perforated and Rewind Sheet Coils The sheet metal blanking line is specifically made to produce raw materials for perforated coils. The fundamental procedure of coil perforated machine involves unrolling, punching, and winding the coil into raw materials for perforated coils. Several different industries use the coil perforated raw material. |

Reference Drawing Of Perforated Sheet

By replacing the punching die, KINGREAL's sheet metal blanking line can process various types and diameters of holes on metal sheets, including common round holes, square holes, slot holes and rectangular holes, etc. If you have special punching shape requirements of coil perforated machine, please provide the design drawings to KINGREAL, and KINGREAL's engineers will customize the appropriate punching die for metal coil perforated making machine according to your requirements.

Coil Perforation Line After-sales Service

KINGREAL can provide on-site sheet metal blanking line installation services to customers. So far, KINGREAL engineers have traveled to Turkey, Brazil, Saudi Arabia, the United Arab Emirates, India, Greece and North Korea to install coil perforated machines.

KINGREAL engineers are responsible for the assembly of the metal perforation line and debug the metal coil perforated making machine to fully meet the production requirements of customers. In addition, they will provide detailed operating instructions and training to workers to ensure that the metal coil perforated making machine and metal perforation line can run efficiently.

Welcome to consult KINGREAL sheet metal blanking line!