Baffle Ceiling Machine

"The baffle ceiling roll forming machine is fully automatic computer controlled type to produce different size acoustic baffle ceiling, and the imported rotary encoder has automatic side length. This metal baffle ceiling production line takes only 1 minute to change from one specification to another. The input specification model is automatically converted and input directly."

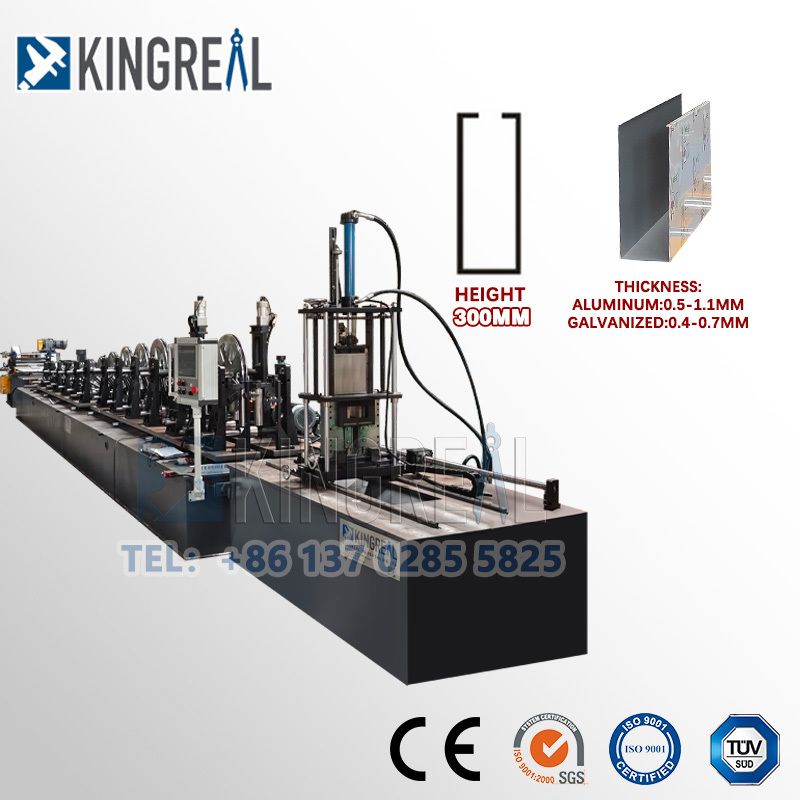

The baffle ceiling machine is KINGREAL's featured equipment. So far, KINGREAL has sold a variety of products such as 100mm height, 200mm height, 300mm height baffle ceiling machines, economical baffle ceiling making machines, and baffle ceiling production lines with feeding trolleys to many countries around the world, including Turkey, India, Russia, Mexico, the Netherlands, Saudi Arabia, and Italy.

In addition, KINGREAL provides customers with a number of detailed services, including accompanying customers to visit the factory, demonstrating the operation of the baffle ceiling machine, formulating customized baffle ceiling production line manufacturing plans, providing customers with professional technical support online 24 hours a day, real-time feedback on manufacturing progress, and offline installation services. Welcome to consult!

1. KINGREAL's innovation in baffle ceiling machines

KINGREAL is committed to providing customized machine solutions based on the actual production needs of customers. Therefore, the parameters of each baffle ceiling making machine sold are different, and they will be adjusted according to the specific needs of customers, including parameter modifications and the addition and removal of components.

(1) Innovation in safety assurance

In cooperation with an Italian customer, the customer pointed out that the biggest challenge in the production process is how to ensure the safety of workers. Since workers are often injured due to carelessness or other reasons when the machine is operating, KINGREAL engineers designed a baffle ceiling making machine with a protective shield after fully understanding customer needs and studying their production habits. The main roll forming machine is wrapped by the protective shield, which greatly improves the work safety of workers. At the same time, this design also effectively solves the problem of metal fragments splashing, protects the environment of the factory workshop, and ensures production safety and cleanliness.

(2) Breakthrough in size innovation

The common baffle ceiling production line on the market can usually only produce products with a height of 35-200mm and a width of 30-100mm. However, in response to the demand of the well-known brand Douglas for large-sized baffle ceilings, KINGREAL innovatively designed a baffle ceiling machine that can produce heights ranging from 35mm to 300mm and widths ranging from 50mm to 100mm. Due to the large product specifications, KINGREAL engineers also upgraded the forming roller of this baffle ceiling making machine to a hollow roller to better achieve roll forming, improving production efficiency and product quality.

2. KINGREAL has rich project experience

KINGREAL has accumulated rich experience in receiving customers from many countries. Through various project cooperation, KINGREAL's engineers have a deep understanding of the specific needs of different regions for baffle ceiling machine parameters. This enables KINGREAL's staff to fully investigate the production environment and market characteristics of the customer's country in the early stage of customer reception, so as to propose a preliminary u baffle machine manufacturing plan in combination with the customer's own needs. This preliminary preparation work significantly reduces the communication cost in the later stage and improves efficiency.

In addition, KINGREAL also actively listens to their feedback and suggestions on u baffle machines through regular return visits to customers. This practice not only helps KINGREAL understand the specific needs of customers for machine parameters and accessories, but also provides a valuable basis for future upgrades and innovations of baffle ceiling machines. According to the actual use of customers and changes in demand, KINGREAL can timely adjust and optimize the design of baffle ceiling machines to ensure that the products always maintain market competitiveness.

Through these measures, KINGREAL has not only improved customer satisfaction, but also consolidated long-term cooperative relations with customers, further promoting the company's continuous development and technological progress.

3. Features of baffle ceilings

Baffle ceilings are not only suitable for home decoration, but also widely used in engineering decoration. Its smooth lines and distinct effects make the baffle ceiling have a strong sense of hierarchy and neatness. In addition, the installation and maintenance of baffle ceilings are very convenient, and they can reasonably hide the air conditioning system, lighting, fire-fighting equipment and related wires, keeping the decoration simple and unified.

Common types of baffle ceilings on the market include U-shaped and V-shaped, usually made of materials such as galvanized sheet, aluminum sheet and roll-coated sheet. In addition to these, KINGREAL can also provide baffle ceiling machines for producing U-shaped baffle ceilings with U-bent, and can provide baffle ceiling carrier machines, which can combine the produced baffle ceiling carriers with baffle ceilings to form a complete baffle ceiling system.

If you have a need for more special types of baffle ceilings, please provide drawings to KINGREAL. Our engineers will develop a personalized baffle ceiling machine manufacturing plan for you to ensure that your specific requirements are met.