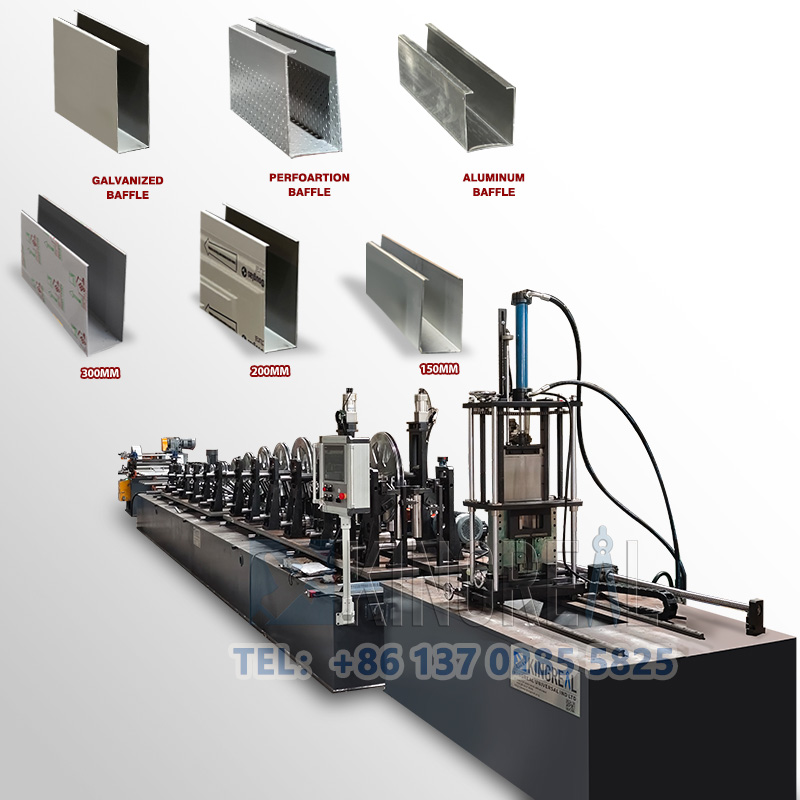

Baffle Ceiling Roll Forming Machine

The baffle ceiling roll forming machine is fully automatic computer controlled type to produce different size acoustic baffle ceiling, and the imported rotary encoder has automatic side length. This metal baffle ceiling production line takes only 1 minute to change from one specification to another. The input specification model is automatically converted and input directly.

- KINGREAL

- China

- 80 Days

- 9999

- Information

- Download

KINGREAL Automatic Baffle Ceiling Roll Forming Machine

-300MM U Baffle Ceiling Machine

-200MM Baffle Ceiling Roll Forming Machine

-150MM Acoustic Baffle Ceiling Machine

-Economical Baffle Ceiling Production Line

300MM Baffle Ceiling Roll Forming Machine |

150MM Baffle Ceiling Making Machine |

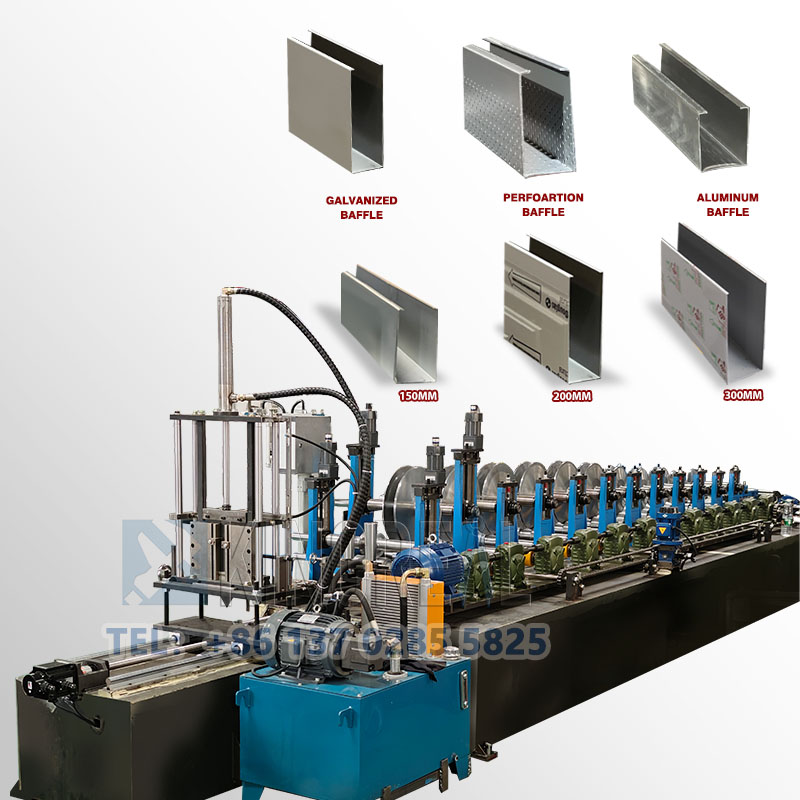

KINGREAL Baffle Ceiling Roll Forming Machine is design for producing U-shaped baffle ceilings. These ceilings are commonly used in commercial buildings such as shopping centers and subway stations because they are not only visually appealing, but also function to improve the acoustic performance of the space. Baffle ceiling making machines can handle metal strips of different sizes and thicknesses to produce U-shaped baffles in a wide range of widths and heights.

The main features of the baffle ceiling machine include:

- High precision guide post mechanism

- Forming rolls: typically 14 forming stations

- Maximum speed: 0-30 meters per minute

- Coil thickness: 0.6-0.9mm

- Automatic specification change: PLC and touch screen control allows for quick change to different specifications

In addition, this machine can produce baffle ceilings with and without holes to meet different design and functional requirements. If you have specific design requirements for the baffle ceiling machine, you can provide design drawings so that engineers can give suggestions.(sales@kingreal.org) These machines are indispensable for metal ceiling projects because they produce the desired ceiling assembly quickly and accurately.

Equipment Features

- High-precision guide column machine - Forming roller: 14 roll forming stations- maximum speed: 0-30m/min - Baffle roll Forming thickness: 0.6-0.9mm - U shape Baffle roll forming machine Unit includes: Uncoiler, servo automatic variable specification, roll forming machine, automatic With cut off, control box. |

|

Why Choose KINGREAL Baffle Ceiling Machine

①Full Automatic The full automatic U baffle ceiling roll forming equipment is fully automatic computer controlled type, and the imported rotary encoder has automatic side length. It takes only 1 minute to change from one specification to another. The input specification model is automatically converted and input directly. |  |

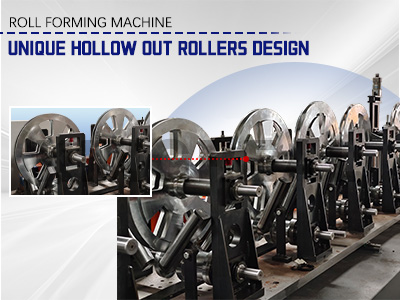

| ②Professional Technical Level KINGREAL has a professional technical team and rich project experience in BAFFLE CEILING FORMING MACHINE, and is able to provide diversified design solutions to meet customers‘ needs. Featured designs include: - Skeletonized roller design, production of 300MM high BAFFLE CEILING products, and cooperation with Hunter Douglas. - ROLL FORMING MACHINE adjustable width and narrow design, through the design of servo motors, only need to input the size range on the touch screen to realize the automatic adjustment of width and narrowness, to produce different sizes of U BAFFLE CEILING - The design of the protective cover meets the needs of customers who require a high level of production safety. |  |

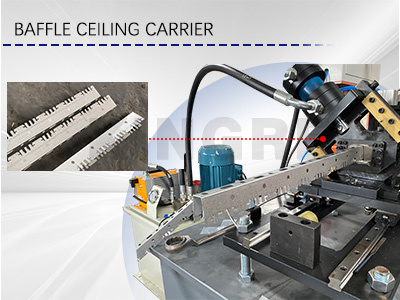

③The Complete Matching Program KINGREAL can supply the Baffle Ceiling Carrier Roll Forming Machine, which design to produce the metal baffle ceiling carrier. the whole production including combine decoiler & straightener, auto punching machine, roll forming line part, shearing part and electrical control system. |  |

Application Of The Baffle Ceiling

KINGREAL baffle ceiling roll forming machine can produce baffle ceilings of various sizes with a width range of 25-100mm and a height range of 75-300mm. This design enables the baffle ceiling machine to meet the specific requirements of different customers for baffle ceilings and adapt to diverse market demands.

In addition, KINGREAL baffle ceiling roll forming machine also supports the production of various types of baffle ceilings, including U-shaped, V-shaped, and U-shaped baffle with U bent. This means that customers can choose the appropriate baffle ceiling according to their own engineering needs and aesthetic standards to achieve a more personalized and beautiful architectural effect.

Vlog Of Packing& Shipping Baffle Ceiling Roll Forming Machine

KINGREAL Technical Team

KINGREAL is not only integrating R&D, have our own technical team and factory, but also have many years of experience in the design and manufacture of Baffle Ceiling Roll Forming machines. We have successfully customized squared ceiling production lines to meet the needs of customers in many countries, including Turkey, the United Arab Emirates, Russia, India and so on.

KINGREAL has established the localized technical support team in Mexico, Russia, United Arab Emirates, Turkey, India and etc.. Localized service points in other countries are also in progress.

Customer Visit

It is such a delight to have friends coming from afar. KINGREAL is warmly welcome customers to visit our factory and communicate with us!