Open Cell Ceiling Machine

"KINGREAL open cell ceiling grilyato production line is also called grill ceiling machine, which is one of our most featuring products can provide all kinds of solution for the open cell ceiling. KINGREAL open cell ceiling machine including the material decoil part, punch part, forming machine and the final product collecting parts."

1. What is a grilyato ceiling machine?

Open cell ceiling machine is a device specially used to produce open cell ceilings. The main raw materials used include metal coils such as galvanized steel (Gi Steel), aluminum, pre-coated galvanized steel or aluminum. Through a series of process flows, including uncoiling, leveling, punching, cutting and forming, the open cell ceiling production linecan efficiently produce various types of grilyato ceilings, such as the common U10, U15, C-shaped, and pyramid grilyato ceilings.

2. KINGREAL can provide multiple open cell ceiling solutions

KINGREAL not only provides open cell ceiling machines, which use grilyato ceilings as keels to form a complete open cell ceiling system. It can also provide ceiling t bar machines, which use the produced ceiling t bar as the keel to form a grilyato ceiling system with a surround. KINGREAL provides customers with two complete open cell ceiling solutions, which greatly improves the customer's flexibility of choice. KINGREAL engineers have visited the Vietnamese customer's factory to help customers install the open cell ceiling machine, and work with customers to use the newly produced finished products to splice the ceiling t bar and the grilyato ceiling to ensure the perfect combination of the system.

3. Features of KINGREAL's open cell ceiling production line

(1) High-end open cell ceiling machine

In order to improve the production efficiency of customers, KINGREAL engineers designed a high-end open cell ceiling machine, upgrading the punch of the standard grilyato ceiling machine from 16 tons to 63 tons. This upgrade enables the machine to punch a row of holes at one time, ensuring the consistency and accuracy of the hole positions. This grilyato ceiling machine has received high praise and recognition from customers in Russia, Turkey and other countries who have high requirements for production scale and efficiency.

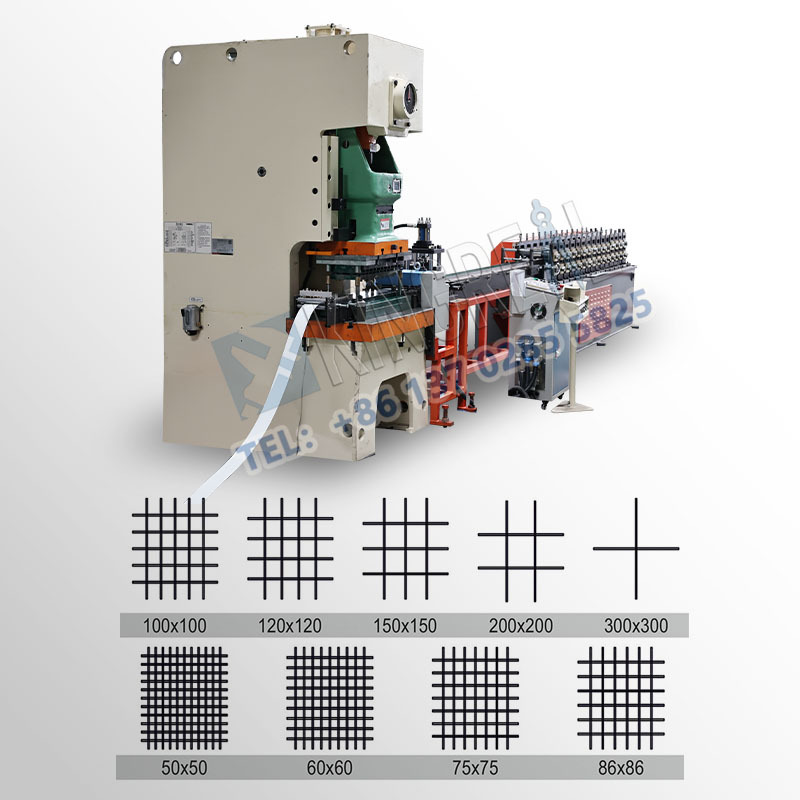

(2) Multi-size production capacity

KINGREAL open cell ceiling production line can process two metal raw materials, aluminum and iron, to produce open cell ceilings of different sizes and materials. This flexibility is mainly achieved by adjusting the roller group, which meets the customer's demand for open cell ceilings of multiple specifications and reduces the cost of customers purchasing multiple machines. Many customers in India and Saudi Arabia have praised this innovation, saying that it has greatly facilitated their production.

(3) Quality assurance

KINGREAL strictly controls every link in the manufacturing process of the grilyato ceiling machine. From the stage of raw material selection, KINGREAL has high standards for material quality. All raw materials must undergo rigorous testing, and those that do not meet the requirements will be returned. During the open cell ceiling machine manufacturing process, KINGREAL has a special inspection team that regularly patrols the processing workshop for supervision and irregular spot checks. Finally, after the open cell ceiling machine is manufactured, the machine will undergo a series of tests, including running stability, whether the product size meets customer requirements, whether the finished product accuracy meets the standards, and whether the surface is smooth and burr-free. Only after passing the inspection will KINGREAL carefully pack each component to ensure safe delivery to the customer's factory.