Open Cell Ceiling Grilyato Production Line

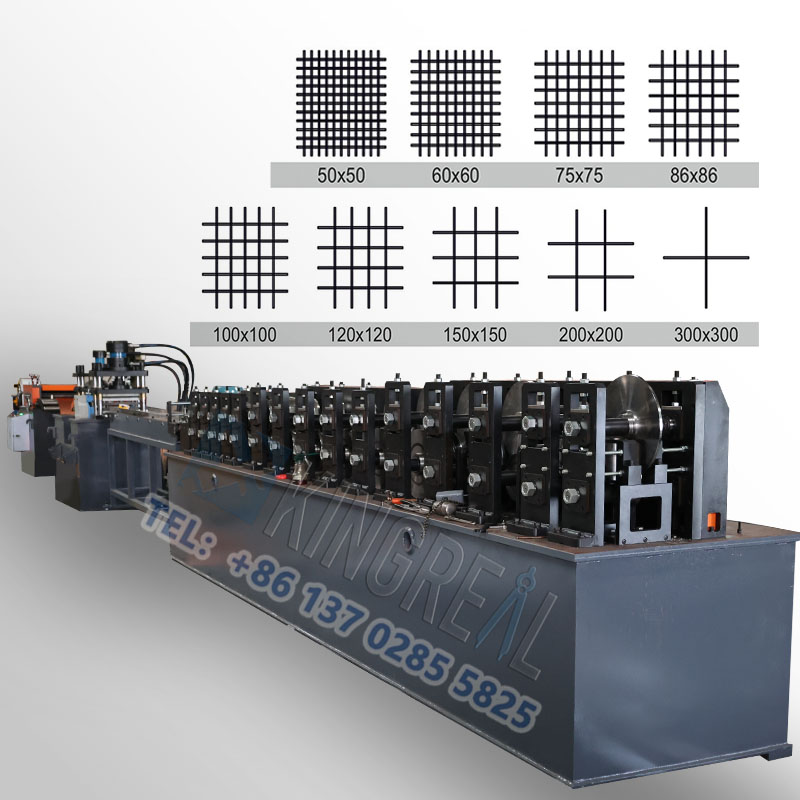

KINGREAL open cell ceiling grilyato production line is also called grill ceiling machine, which is one of our most featuring products can provide all kinds of solution for the open cell ceiling. KINGREAL open cell ceiling machine including the material decoil part, punch part, forming machine and the final product collecting parts.

- KINGREAL

- China

- 80 Days

- 9999

- Information

- Download

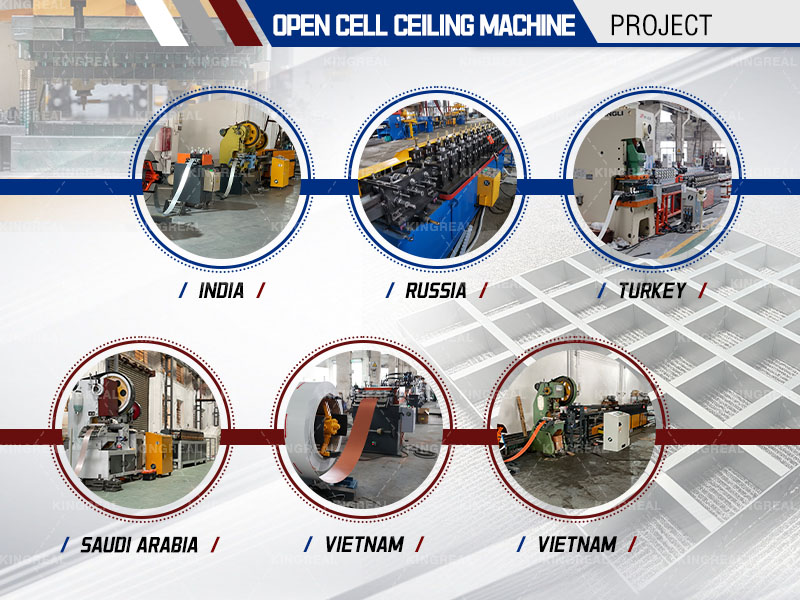

Open Cell Ceiling Machine Successful Projects in Global

KINGREAL can provide customers with different open cell ceiling machines to meet different production needs. At present, KINGREAL's grid metal ceiling machines have been sold to many countries, including India, Russia, Turkey, Saudi Arabia, Vietnam and other countries. Among them, KINGREAL has sold many different models, including U-shaped open cell ceiling machine, C-shaped open cell ceiling machine, pyramid open cell ceiling machine, open cell ceiling machine with protective shield, standard open cell ceiling machine and high-end open cell ceiling machine, etc.

KINGREAL will make customized open cell ceiling machine manufacturing solutions for customers. Therefore, if you have special production needs, you are welcome to give the drawings to KINGREAL. The engineer will give a satisfactory open cell ceiling making machine manufacturing solution after full communication with the customer.

Description Of Open Cell Grigliato Production Line

Our open cell ceiling machine is also called grill ceiling machine and grigliato machine, which is one of our most featuring products can provide all kinds of solution for the open cell ceiling. Our open cell ceiling machine including the material decoil part, punch part, forming machine and the final product collecting parts.

Structure Of Open Cell Ceiling Machine

- Combine decoiler & Leveler - Punch & Shearing - Servo feeder - Main roll forming station - Output table. - Electrical & Hydraulic system |  |

Feature of Open Cell Ceiling Machine

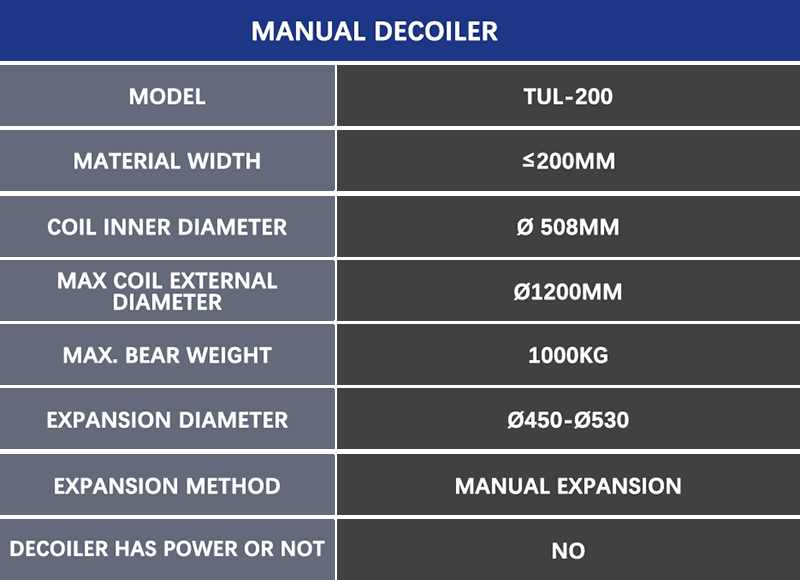

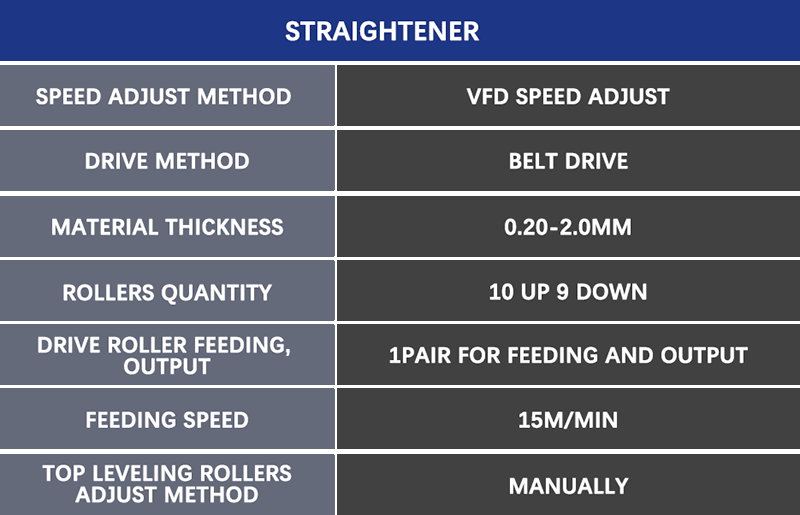

| 1. High Quality Decoiler & Straightener The KINGREAL 2 in 1 decoiler & straightener apply to unwinding and straightening work of coil sheet metal. This combination contains decoiler and straightener. To respond to changing demands, we have hydraulic decoiler and manual decoiler, and optional trolley for full-automatic metal loading. The straightener provides high precision straightening. By doubling the amount of rollers we ensure straightness of materials and high-accuracy finished products. |

|

2.High Precision Cr12MoV forming rollers Cr12mov mold steel, heat treatment hardness up to HRC 580-600. Which is processed by CNC machine after wire cut, 1st lathe machine, then vacuum heat treatment. After strictly following these processing procedures, the forming rollers would be endurable and ensure our machines long time running. |

|

| 3.Online Punch system We use high-speed punching machines, hydraulic punching machines, etc. for online punching of products. After punching, the product can directly enter the roll forming machine for cold bending forming. Our punching machine has the characteristics of fast punching speed, high precision and strong stability. |

|

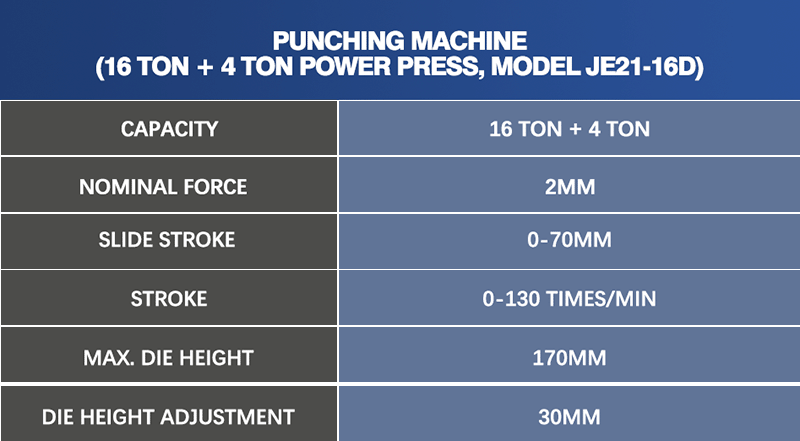

Technical Specification

1) Material Uncoiler Part

2) Straightener

3)Punch Press Machine

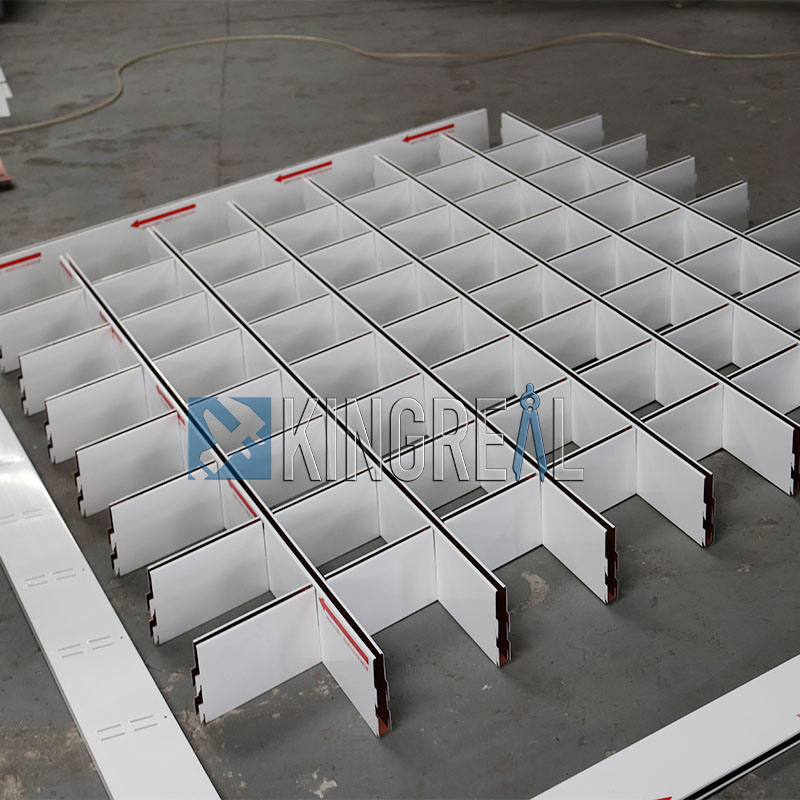

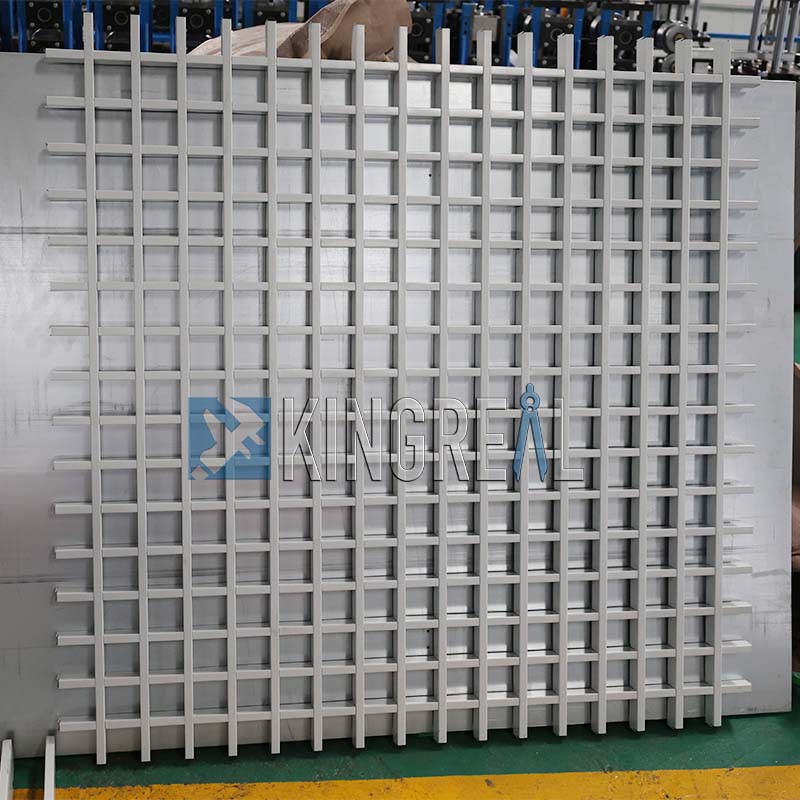

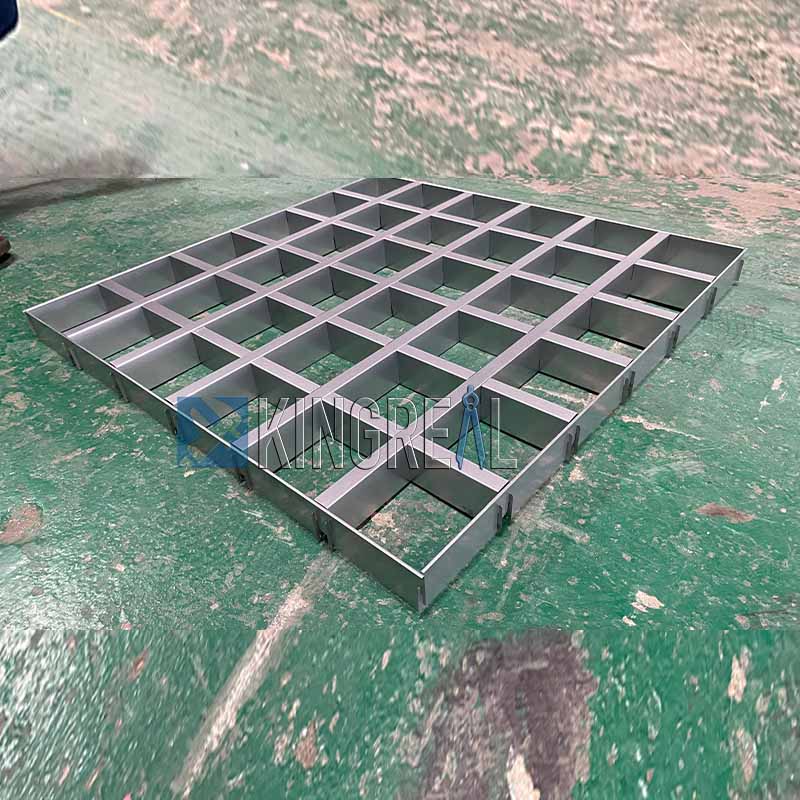

Product Display

After the manufacturing of KINGREAL's open cell ceiling machine is completed, customers will be invited to the factory for on-site testing.

If the customer is unable to come in person due to some reasons, a professional testing team will conduct a comprehensive test of the ceiling grid making machine. During the test, KINGREAL will record key data and provide detailed feedback to customers through high-quality pictures and videos. This transparent communication method ensures that customers can understand the operating status of the ceiling grid making machine in real time and enhance their sense of trust.

In addition, KINGREAL's open cell ceiling machine is highly flexible and adaptable, and can produce open cell ceilings of various sizes and types. This feature allows customers to find suitable solutions for both large commercial projects and small home renovations. Through advanced technology and equipment, KINGREAL is committed to meeting different market needs and providing customers with high-quality products and services.

Diverse Open Cell Ceiling Solution

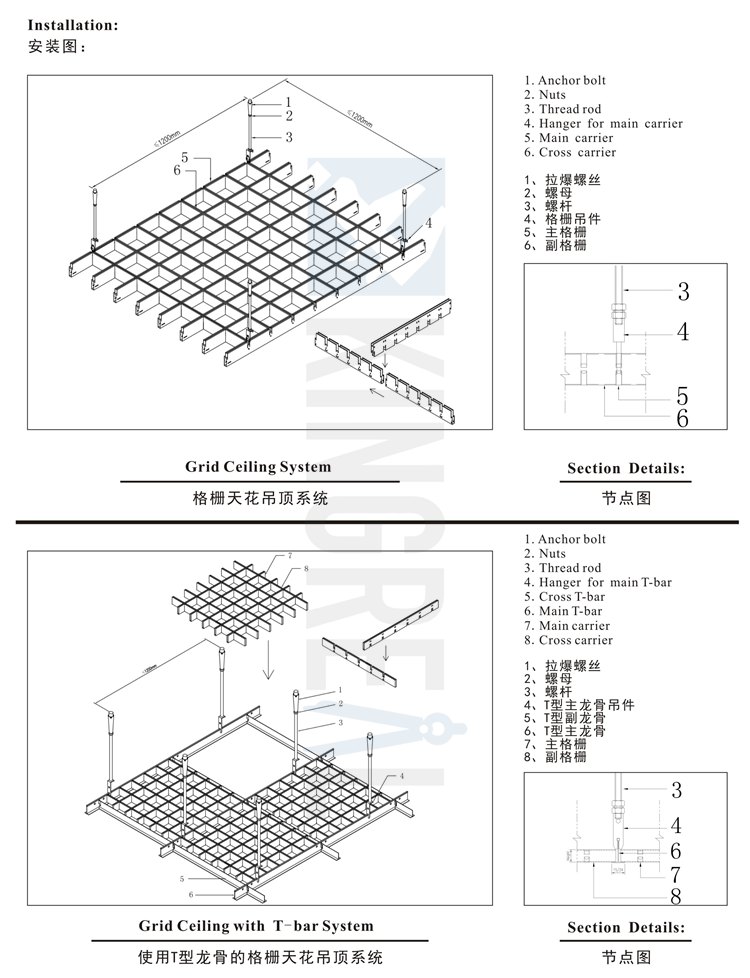

KINGREAL can provide customers with different open cell ceiling solutions. In addition to using a open cell ceiling machine to produce open cell ceilings, which can be assembled and spliced to form a complete grilyato system, KINGREAL also provides a second solution - using a ceiling t bar machine to produce different types and sizes of ceiling t bar as the keel of the open cell ceiling, supporting the ceiling and forming a open cell ceiling with a surrounding edge.

Customer Feedback

KINGREAL will regularly visit customers to ask if they have encountered any difficulties in using the open cell ceiling machine recently and how the KINGREAL open cell ceiling machine performs. One of the Vietnamese customers gave a high evaluation. He believed that after using KINGREAL's ceiling grid making machine, the production efficiency was greatly improved, and the precision of the open cell ceiling produced was greatly improved compared with before. If the production scale is expanded in the future, he hopes to cooperate with KINGREAL again.