Open Cell Ceiling Grid Roll Forming Machine

Automatic Open Cell Ceiling Grid Roll Forming Machine can be offered by China supplier KINGREAL MACHINERY, which can provide customized production solutions based on customer's drawing requirements, etc. to maximize customer's benefits.

- KINGREAL

- China

- 80 Days

- 9999

- Information

- Download

Description Of Automatic Open Cell Ceiling Making Machine

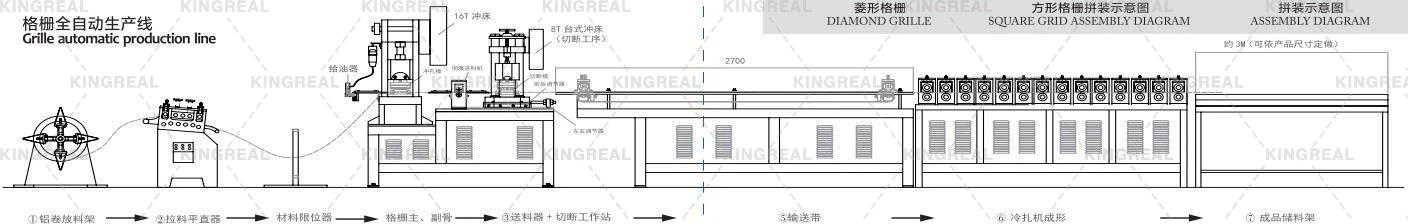

One of our most prominent products is the automatic open cell ceiling roll forming machine, also known as the Grilliato metal ceiling production Line. It includes the following production steps: decoiler of raw materials, hole punching, main roll forming machine, and gathering of finished goods. This machine can make items in a variety of sizes, including 600mm, 1200mm, and 2400mm, among others. Customers have more production options to choose from by changing molds. Galvanized or pre-painted aluminum raw material coils are both suitable with the Grilliato ceiling manufacturing equipment. |  |

Working Process Of Open Cell Ceiling Making Machine

Hydraulic Decoiler -- Precision Leveler -- Perforation Press -- Cut To Length Press Machine -- Main Roll Forming Machine -- Product Output Table

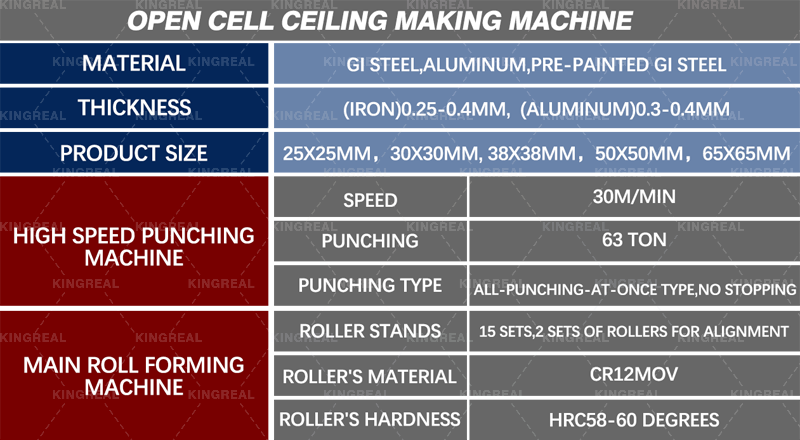

Technical Specification

| Raw material | Gi steel, Aluminum |

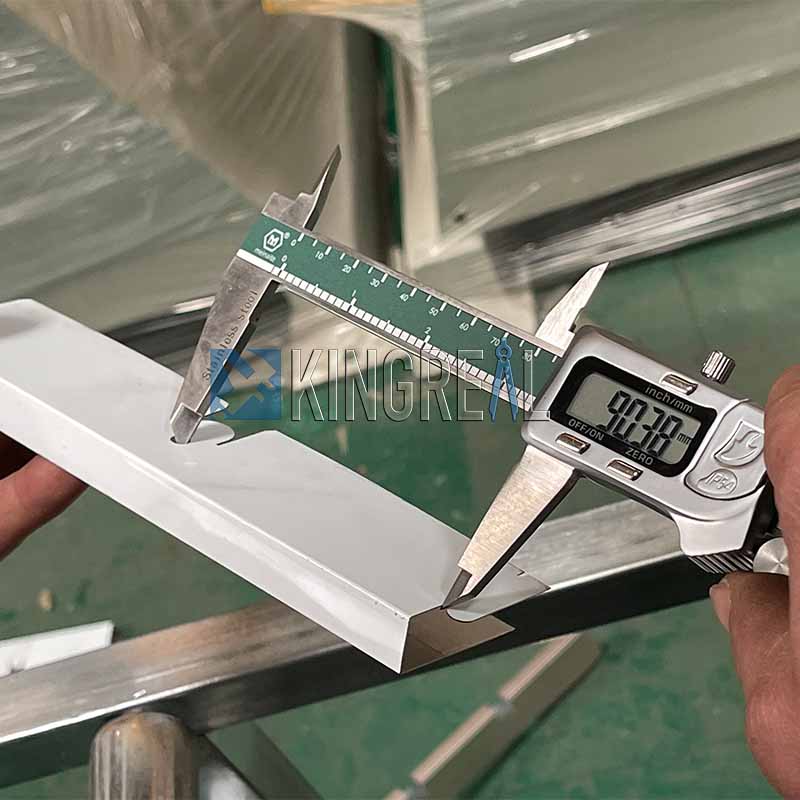

| Product size | 10/15mm width, 30/40/50mm height |

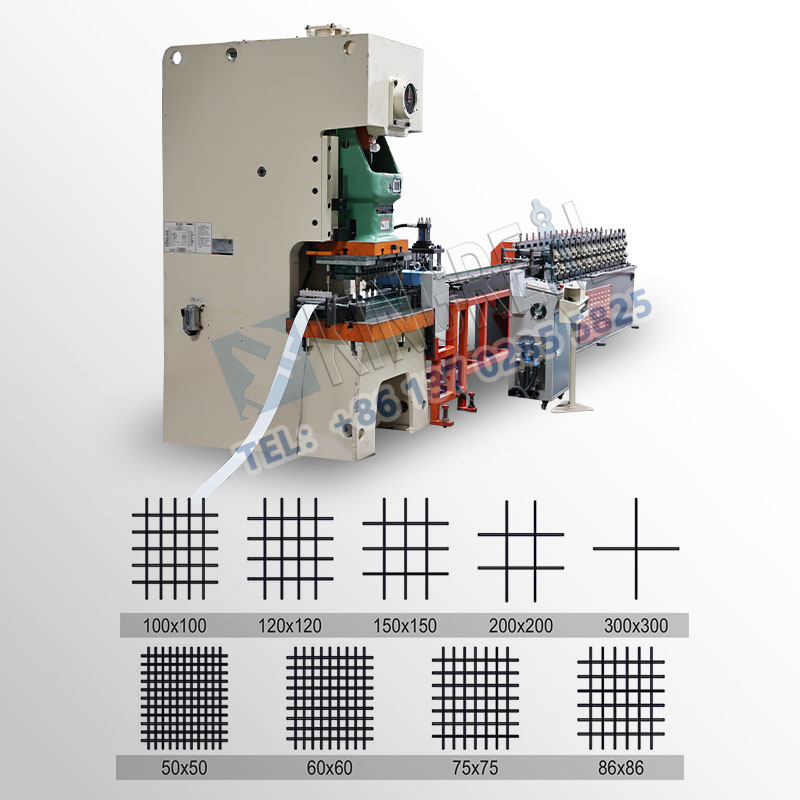

Open cell size | 75*75/100*100/150*150/200*200mm |

| Production capacity | 8-10m/min |

Electricity requirement | 380V 50Hz 3 Phases |

Power consumption | 10KW |

Main Component Detail

1. Unique unrolling design

The KINGREAL 2 in 1 decoiler & straightener is used for coil sheet metal unwinding and straightening tasks. Decoiler and straightener are both present in this combo. We offer a hydraulic decoiler, a manual decoiler, and an optional trolley for fully automatic metal loading in order to adapt to changing demands.

High precision straightening is offered by the straightener. We ensure that the materials are straight and that the completed goods are highly accurate by doubling the number of rollers.

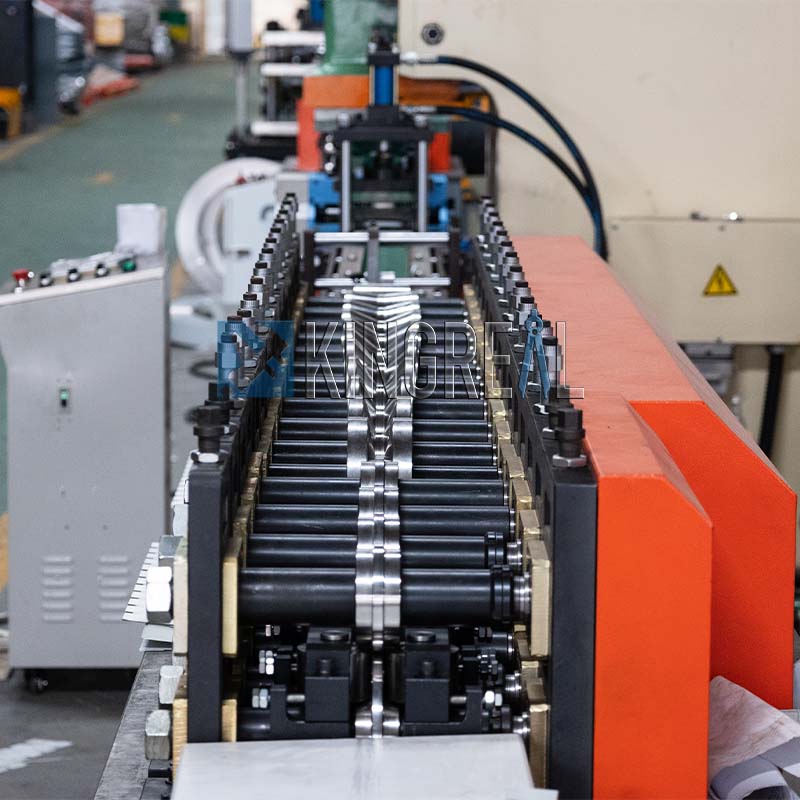

2. Roll Forming Machine -- high precision Cr12MoV Rollers

Cr12mov mold steel has an HRC of 580–600 after heat treatment. which a CNC machine processes.

3. Two Different Perforation Press Station:

KINGREAL can offer two different punching stations, which directly determine the production data of the entire line.

The standard grating machine line has a 16-ton punching machine for the middle punching station.

The high end grating machine upgrades the punching station to a 63 ton punching station compared to the standard grating machine, and the tooling is upgraded to be able to punch a whole line at a time.

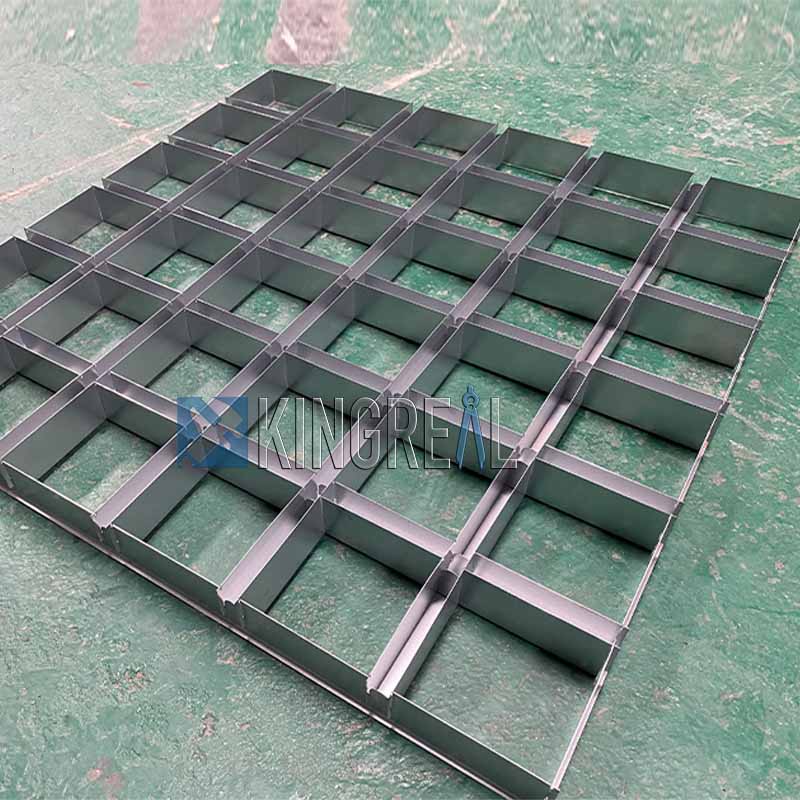

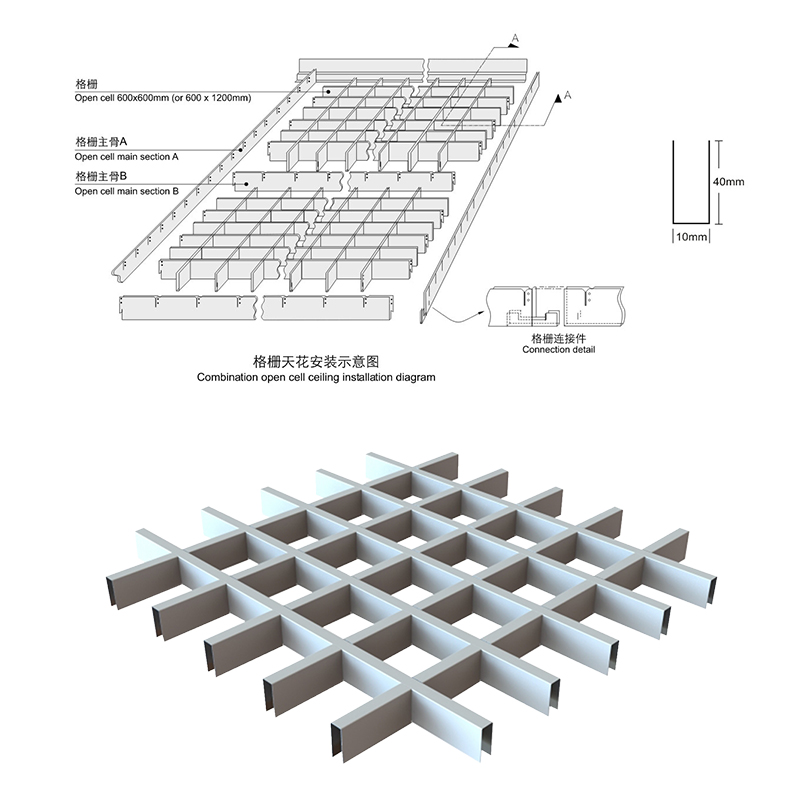

Final Product--Open Cell Ceiling

Quality Insurance

KINGREAL has passed ISO9000 certification and has the ability of ISO9000 quality system management. After you ordered, our technical team will test the machine in an effort to insure every mechanical and electrical parts are in perfect condition.

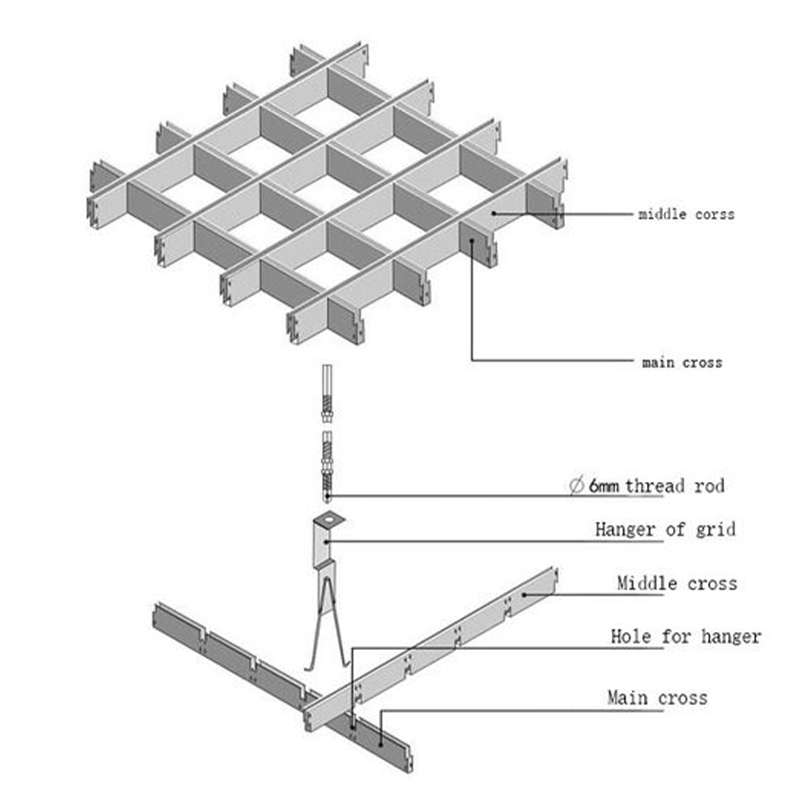

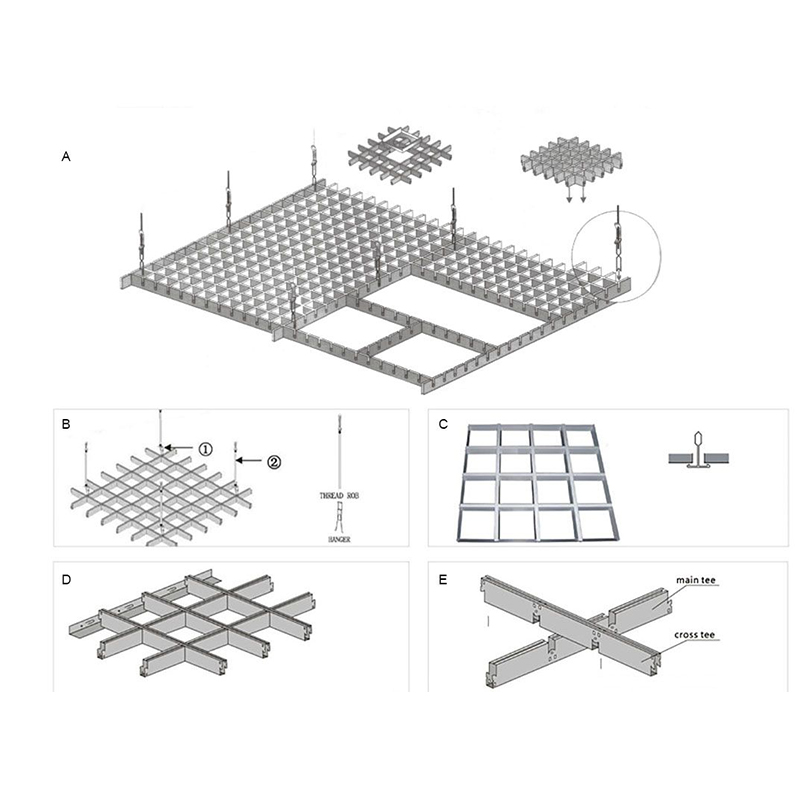

Drawing About Open Cell Ceiling

Installation Service

In order to help our customers to solve machine installation problems, KINGREAL will provide both online and local installation services.

1. Online installation guide

- Photos and videos of machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting

2. Local installation

KINGREAL will arrange engineers to go abroad to install the machine at the customer‘s place to ensure the normal operation of the machine, and will provide all technical guidance. Exact costs to be negotiated.

“KINGREAL techniacal team in Russia”