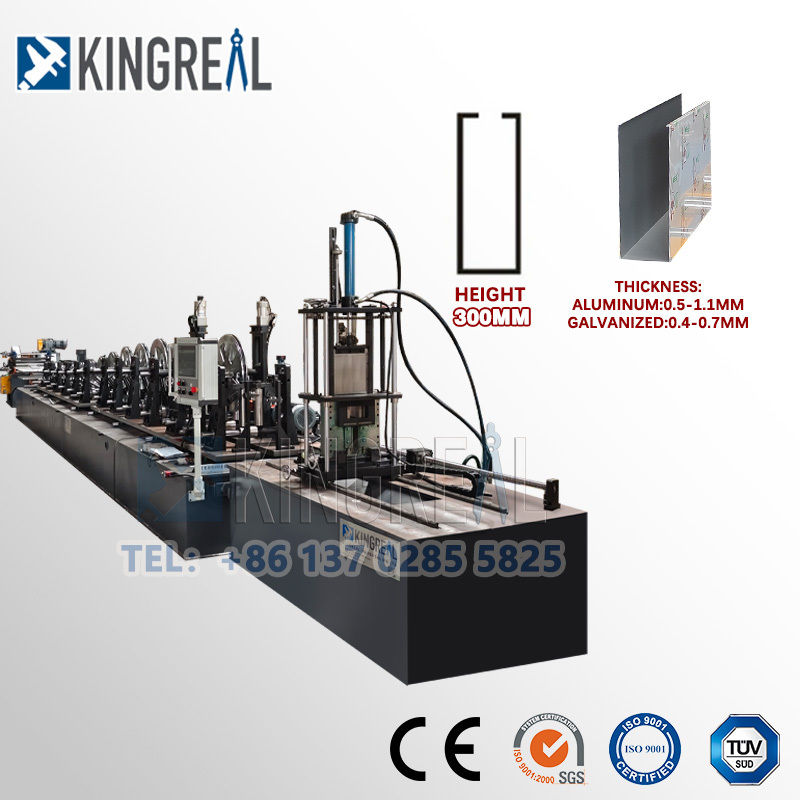

300MM Baffle Ceiling Machine

Are you looking for 300MM high custom U Baffle Ceiling Making Machine, one of KINGREAL most distinctive products, which has been successfully sold to countries such as India, Holland, Mexico and Vietnam! Contact us for machine details!

- KINGREAL

- China

- 80 Days

- 9999

- Information

- Download

Description Of 300mm U Baffle Ceiling Roll Forming Machine

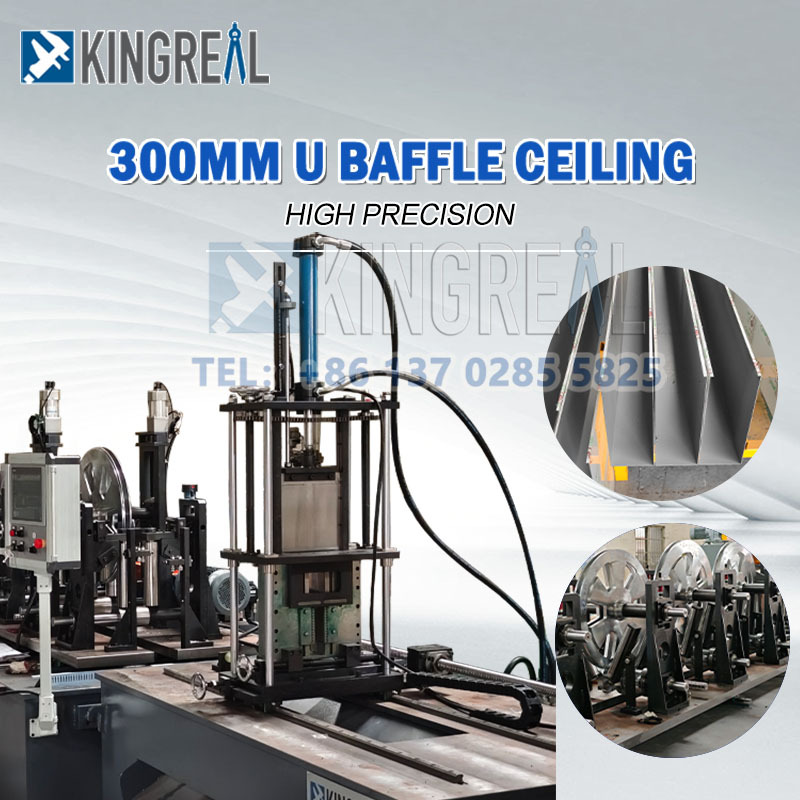

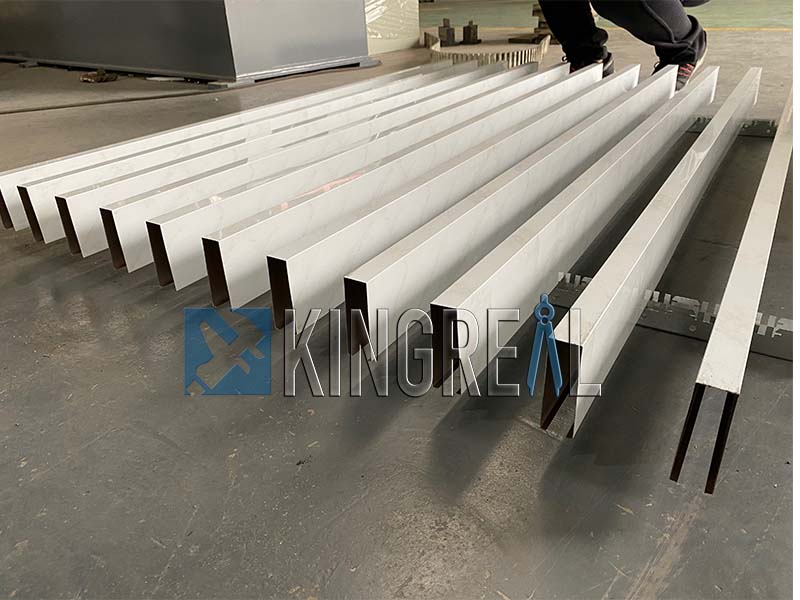

KINGREAL most cutting-edge technology is found in the 300mm U Baffle Ceiling Roll Forming Machine, which was created especially for upscale clients like the Hunter Douglas group. This machine is capable of producing U-shape baffles that are up to 300mm tall.

Technical Specification Of Baffle Ceiling Making Machine

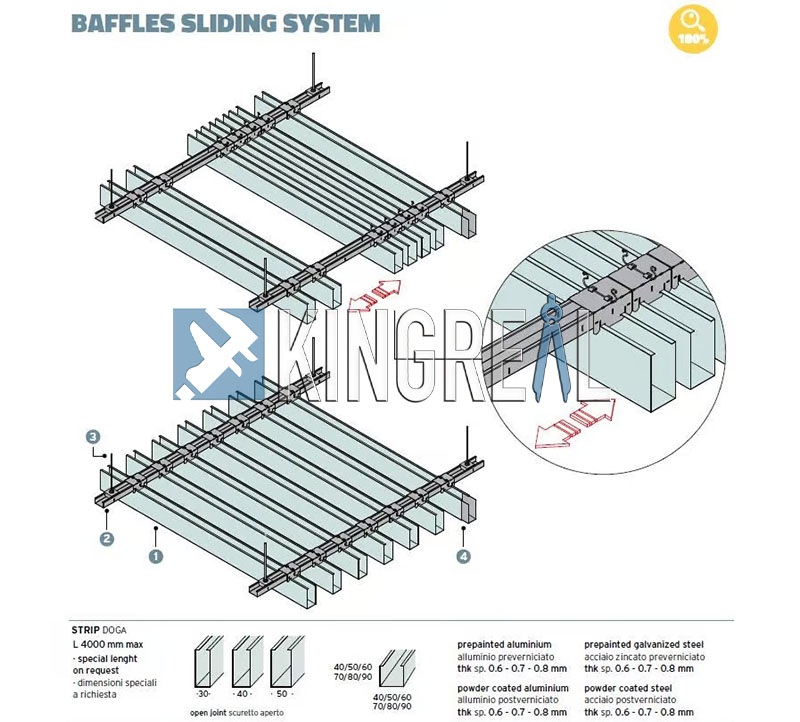

Raw materials | Pre-painted Aluminum or Pre-painted Galvanized steel |

U baffle ceiling sizes | Max height: 300mm, Max width: 200mm |

Width and height adjustable | Automatic servo control |

Maximum forming speed | 35 m / min |

Roll Forming stands | 14 Rollers station |

Machine Power | ~ 30KW |

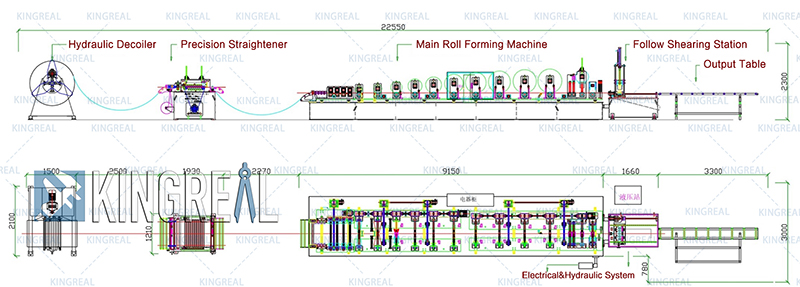

Structure of U Baffle roll forming Machine

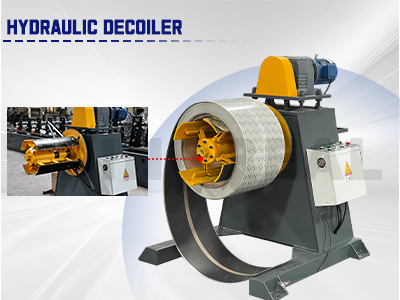

- Hydraulic decoiler - Precision leveler - Main roll forming machine - Follow shearing station - Output table. - Electrical & Hydraulic system |  |

FEATURES - KINGREAL 300MM U-BAFFLE CEILING MAKING MACHINE

1)Decoiler With Hydraulic KINGREAL offer a hydraulic decoiler and a manual decoiler with an integrated hydraulic core expansion system to adapt to changing demands. Additionally, a trolley option is available for fully automatic metal loading. |  |

2)Follow Shearing System at High Speed To ensure continuous operation of the entire manufacturing line, we deploy a high speed follow shearing system. Our high speed follow shearing system drives the cutter via synchronous belt to cut and is typically powered by a high-precision servo feeder connected to a planetary reducer. To ensure swift action and reset, the hydraulic component of the cutter is pressurized. High speed, high precision, and automation are features of the KINGREAL high speed follow shearing system. The BEST option for high-speed automation is this one. |  |

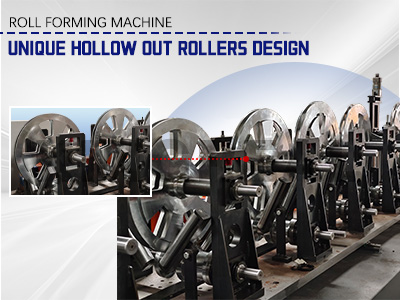

| 3)Unusual Hollow Out Rollers KINGREAL created hollow rollers specifically for the 300mm U baffle roll forming machine to lessen the issue of indentation brought on by the weight of the rollers. This method is especially well suited for machines that make U baffles larger than 200mm. |

|

ADVANTAGES - 300MM U-BAFFLE CEILING MAKING MACHINE

1)Control System For Strict Machine Quality To test various components, our organization has a stringent machine quality control system. For each forming roller—the essential part of a roll forming machine—we will, for example, do a thorough measurement, inspection, and deflection test. To ensure that machines and completed goods are accurate, every possible measure will be taken. |  |

2)Superior hydraulic system The hydraulic components use a hydraulic system with high energy storage efficiency. Additionally, it uses hydraulic components from Germany or Taiwan. It can be used to quickly punch and shear a variety of roll-formed items. |  |

3)High Quality Electrical Appliances KINGREAL use high-quality imported electrical appliances, such as Japanese Yaskawa NC servo feeder, PLC from FATEK, MCGS touch screens, which can ensure stable and continuous work of our machines. |  |

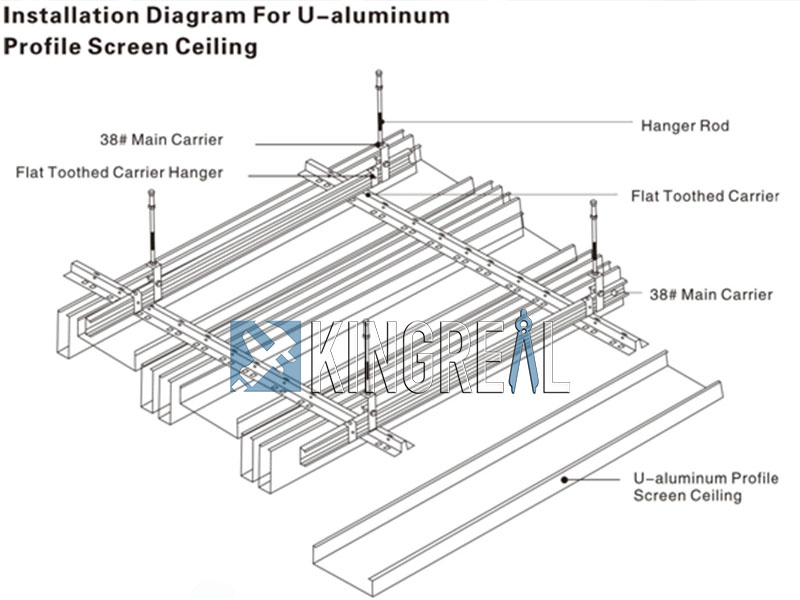

Different Type And Size U Baffle Ceiling

|  |

|  |

Other Featured Suspended Ceiling Machine

①Linear Strip Ceiling Roll Forming Machine

Linear Strip Ceiling Roll Forming Machine is a machine for producing linear strip ceilings.

Features of this machine include:

1. Adjustable Width: Linear strip ceilings of different widths can be produced on the same system, simply enter the desired size on the touch screen and the servo motors will drive the rollers to the requested position.

2. Automatic edge bending: for customers with high-end products, an automatic edge bending function is optional

②Open Cell Ceiling Roll Forming Machine

The Open Cell Ceiling Roll Forming Machine is a specialized machine for the production of Open Cell Ceiling. This ceiling consists of crossed metal strips.

Features of this machine typically include:

1. High-speed perforating press: for fast and accurate perforation of the sheet metal.

2. Hydraulic cutting: ensures precision and neatness in the cutting of the sheet metal.

Quality Insurance

KINGREAL has passed ISO9000 certification and has the ability of ISO9000 quality system management. After you ordered, our technical team will test the machine in an effort to insure every mechanical and electrical parts are in perfect condition.

KINGREAL Technical Team

KINGREAL is not only integrating R&D, have our own technical team and factory, but also have many years of experience in the design and manufacture of Baffle Ceiling Roll Forming machines. We have successfully customized squared ceiling production lines to meet the needs of customers in many countries, including Turkey, the United Arab Emirates, Russia, India and so on.

KINGREAL has established the localized technical support team in Mexico,Russia, United Arab Emirates, Turkey, India and etc.. Localized service points in other countries are also in progress.

KINGREAL Exhibition

1)Control System For Strict Machine Quality

To test various components, our organization has a stringent machine quality control system. For each forming roller—the essential part of a roll forming machine—we will, for example, do a thorough measurement, inspection, and deflection test.

To ensure that machines and completed goods are accurate, every possible measure will be taken.