Metal Coil Perforation Line

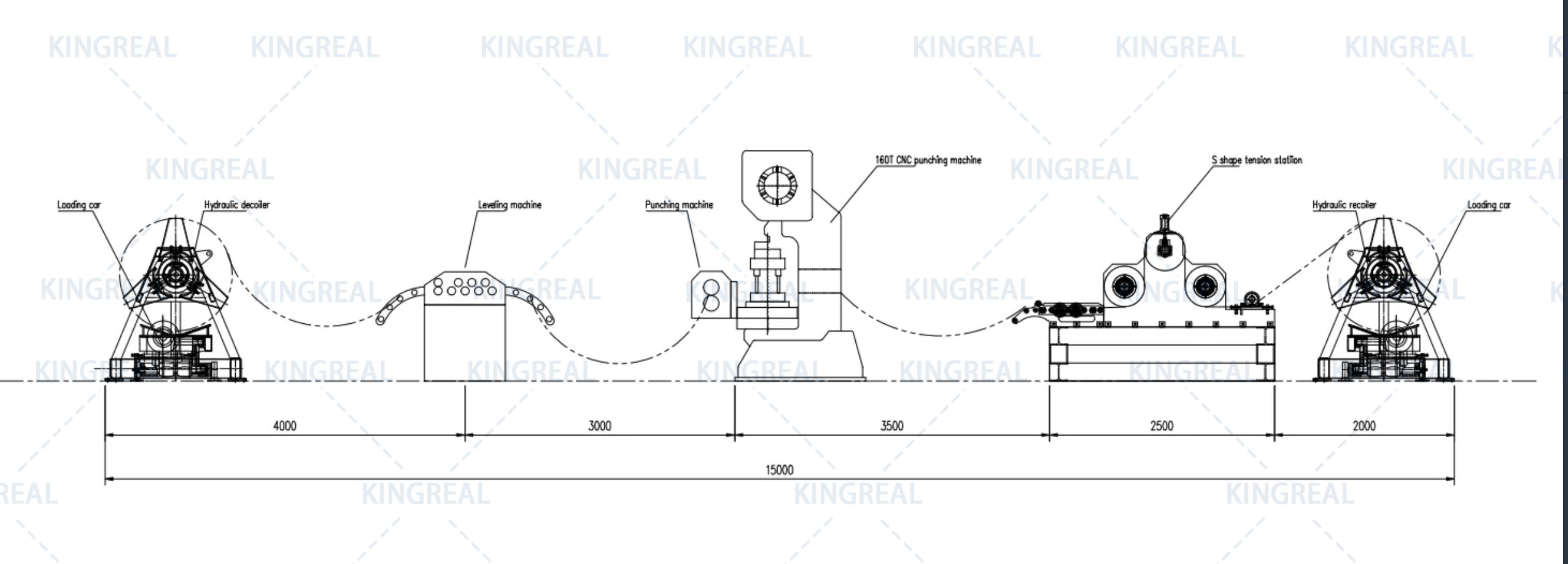

KINGREAL Metal Coil Perforation Line consists of uncoiler with a straightener, a punch, a shearing for length cutting and a rewind, which cooperate with each other to successfully manufacture perforated coil and perforated sheet panel.

- KINGREAL

- China

- 80 Days

- 9999

- Information

- Download

Video Display Of Perforated Metal Machine

Description Of Metal Perforating Machine

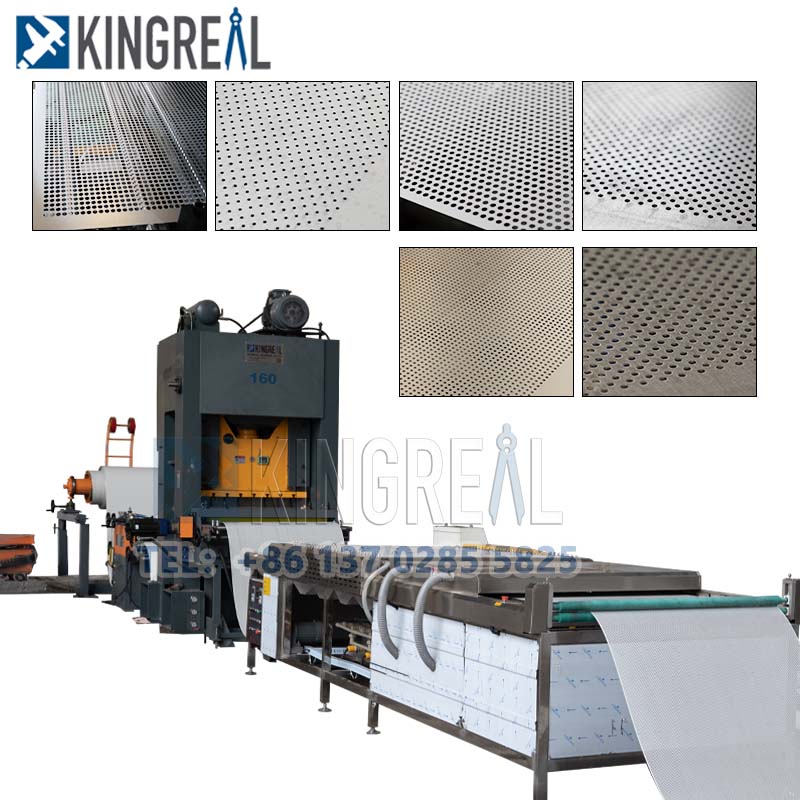

KINGREAL perforated sheet machine consists of components such as an uncoiler, a straightener, a punch, a shearing for length cutting and a rewind, which cooperate with each other to successfully manufacture a perforated coil.

KINGREAL Metal perforated punching machine not only just perforate the metal sheet, but also can perforate the metal coil. And the greatly advantage of perforated sheet punching machine is that can reduces raw materials costs due to mass production. In addition, due to its systematic perforated sheet machine, it has the ability to perforate and short production times. This perforated sheet punching machine reduces labor and utilizes resources efficiently.

The Process Of Perforated Sheet Punching Machine

The detailed work flow of the metal perforating machine is as follows:

Step 1:

The uncoiler with straightener is responsible for feeding the normal coils easily into the feed rollers of the perforated metal machine.

Step 2:

Then advancing forward in the process, the punch will do its job to punch out the predefined hole, thus perforating the coil.

Step 3 :

Finally when the desired length is reached, the punching system will stop and cut by the designated shear to cut the sheet.

Depending on the customer, if they wish to perforate the entire coil, the coils will not be cut, but will immediately go to the rewinding step.

Main Components Details Of Perforated Sheet Machine

High Precision Straightener KINGREAL perforated punching machine is equipped with high precision straightener. It is professional 19 rollers flatting device with 9 top roller and 10 bottom roller which avoid the deformation of the roller. The upper roller can be adjusted on the same time and the rollers diameter is 58mm. it is hard-chrome plated to ensure the surface smoothness, strength and endurable to avoid the scratch of the tiles surface. This part is used for flatting the coil material to make the surface flat so the punch can be more accurate. The motor is 3kw and drive through cycloidal pin gear speed reducer motor which featured with fast response and high precision. |  |

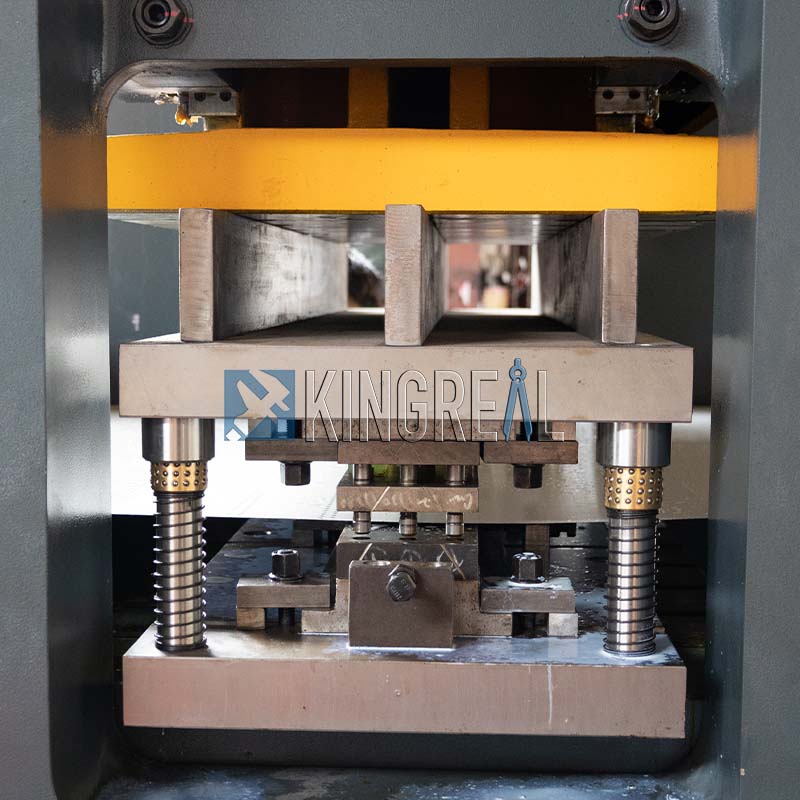

High Quality Punching Machine The punching equipment in the perforated punching machine is a kind of mechanical equipment used for punching operation on the plate. It usually consists of a frame, a punch, a working table and a control system. It is a kind of mechanical equipment that penetrates the tool through the plate by impact force, and it has stable structure, strong bearing capacity and automatic control function, which can realize efficient and precise punching operation. |  |

Servo Motor Feeding Device KINGREAL perforated punching machine has strong servo motor feeding device. The feeding roller is 90mm diameter and hard-chrome treated. It is drive by 3.0 KW servo motor and featured with fast response and high precision. And accuracy can reach ±0.2mm. |  |

Metal Sheet Cleaning Machine To meet customers' high requirements for the cleanliness of the metal sheet surface, KINGREAL's perforated sheet machine can be equipped with a fully automatic metal sheet cleaning machine. After the metal sheet is punched on the perforated metal machine, the sheet will be directly sent to the plate washer for thorough cleaning. The metal sheet cleaning machine can remove surface dirt, grease and other impurities, thereby ensuring the excellent quality of the sheet in subsequent processing and use. This process not only improves the appearance of the product, but also effectively extends the service life of subsequent processing equipment. |  |

| Recoiler

KINGREAL equipped the perforated metal machine with a recoiler, it can automatically and quickly wind up the punched sheet, significantly improving production efficiency. The recoiler can neatly wind up the punched sheet for easy transportation and storage. Perforated metal machine with recoiler not only saves labor costs, but also maximizes storage space, providing customers with more flexible logistics solutions. |  |

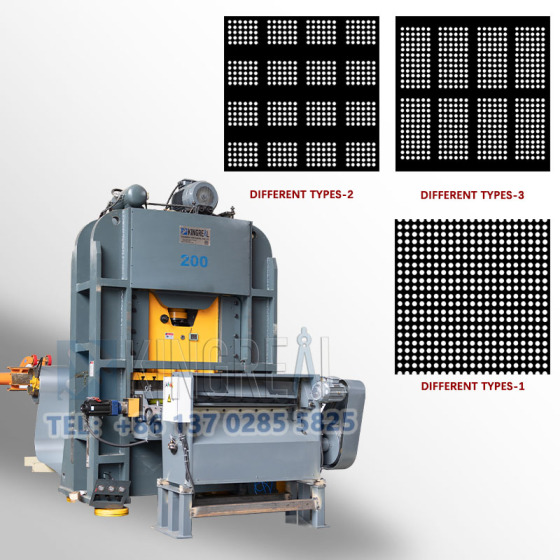

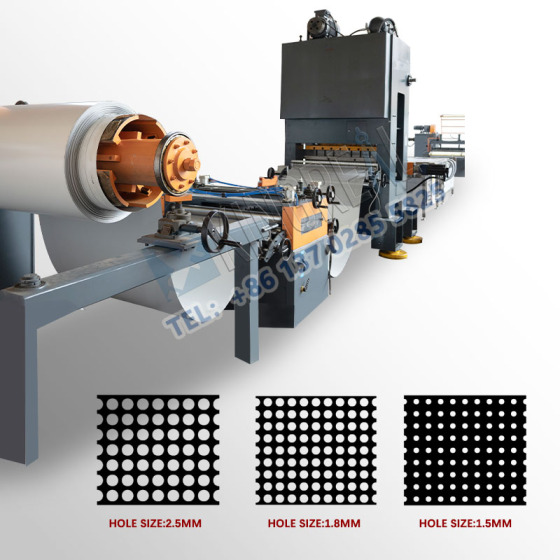

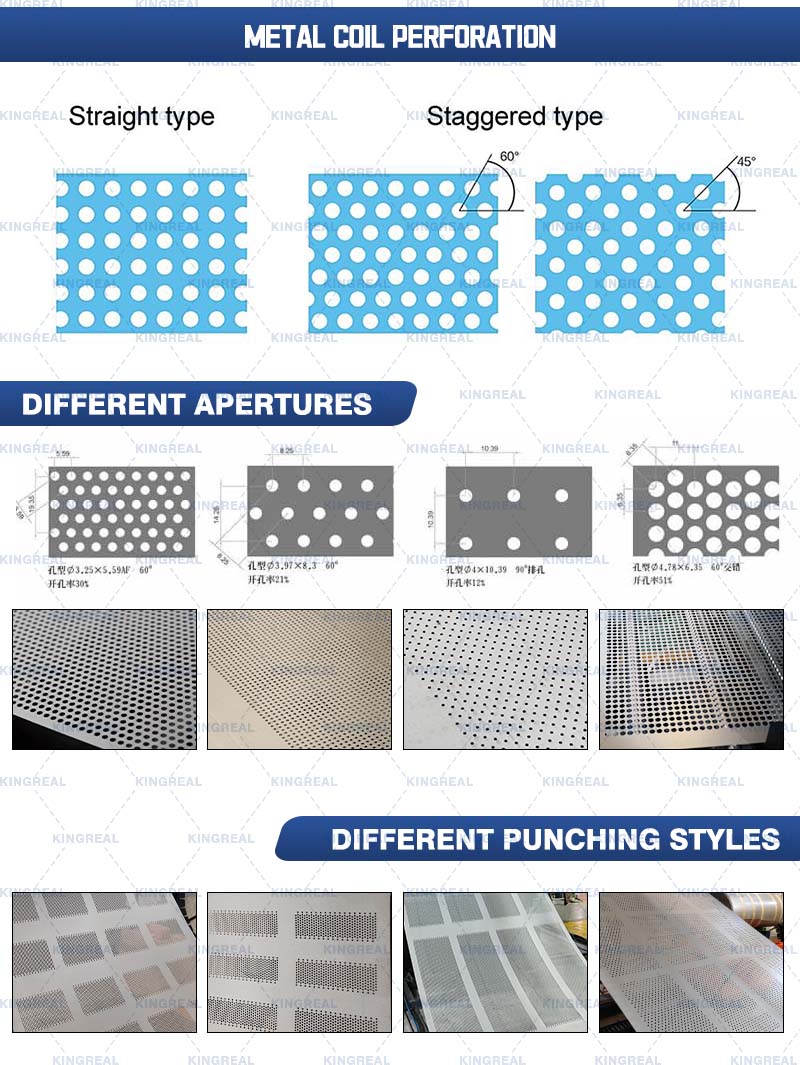

Perforation hole selection

The most common patterns that the perforated metal machine can punch out are square and square staggered patterns, which by the way can all be obtained with the same piercing tool, just remove half of the punch. Apertures can be as small as 0.7mm to 3mm or even larger. The most common sizes are from 1,5 mm to 2,5 mm, the distance between the holes is usually from 0.4 to 0.6 mm.

KINGREAL Perforated Sheet Machine In Factory

KINGREAL has a complete and rigorous work process for the manufacturing of perforated sheet machines. KINGREAL is very strict in the selection of raw materials for the manufacture of perforated punching machine. After the perforated sheet punching machine is manufactured, KINGREAL engineers will put in metal raw materials for testing, mainly testing the punching speed of the metal perforating machine, whether the perforated sheet machine can complete the punching of various hole types, Whether the metal perforating machine can produce high-precision finished products, etc. Only the perforated punching machines that successfully pass the test will be sent to the customer's factory. Therefore, the quality of KINGREAL perforated metal machine is completely trustworthy.

And KINGREAL welcomes customers from all over the world to come to the factory to visit the perforated metal machine. KINGREAL staff will invite customers to deepen their understanding of the perforated metal machines by personally operating the perforated punching machines and visiting the perforated sheet machine production workshop.

Successful Metal Perforating Machine Project

KINGREAL is an experienced professional perforated punching machine manufacturer, and KINGREAL metal perforating machines have been sold to Brazil, Greece, UAE, etc. KINGREAL deeply understands the different requirements of various countries for metal perforating machine parameters, and can provide corresponding customized metal perforating machine manufacturing solutions for customers in different countries.

If you are interested in perforated sheet punching machine, welcome to consult! There is a professional technical team here to answer any perforated sheet punching machine questions for you. In addition, KINGREAL is good at providing customized perforated sheet machine manufacturing solutions for customers!