KINGREAL 600*600 Ceiling Tile Machine In Turkey

2024-09-10 13:42KINGREAL 600*600 Ceiling Tile Machine In Turkey

Recently KINGREAL has successfully transported the Metal Ceiling Production Line to the customer in Turkey. The Turkey market, as KINGREAL‘s most important sales market for ceiling equipment, has already accumulated:

1. Full Auto Metal Ceiling Tile Production Line

2. Metal Ceiling Perforated Production Line

3. Metal Ceiling Bending Forming Press Machine

4. Different Type Perforated Punching Mold

And so on.

Introduction of KINGREAL Featured Products

Full Auto Metal Ceiling Tile Production Line

KINGREAL's fully automatic metal ceiling tile machine is a powerful and efficient equipment that can provide customers with flexible and precise ceiling production solutions. Its main features include:

- Multi-size production capacity: This production line can produce ceilings of different sizes, such as the common 30x30cm, 60x60cm, 60x120cm and other sizes to meet different architectural and decorative needs.

- Multi-type ceiling production: By replacing different bending plate modules, the metal ceiling panel machine can easily manufacture various types of ceilings, including CLIP IN, LAY IN, Tegular, etc. The mold replacement is very simple, which not only saves time, but also avoids the cost of purchasing other different machines, making the production process more flexible.

- Fully automatic control system: KINGREAL's metal ceiling making machine adopts a mechanical control system, which is sensitive and precise, without manual intervention, and can ensure precise control of each link in the production process. This automated design not only reduces the reliance on manual labor, but also greatly reduces human errors and production safety hazards. Through automated control, enterprises can reduce labor costs, improve production efficiency, and save labor.

Metal Ceiling Perforated Production Line

With the diversified needs of metal ceilings, metal ceiling perforated production lines have emerged to provide customers with more design options and functional requirements. This production line has the following advantages:

- Strong compatibility: The metal ceiling perforation production line can be used with the metal ceiling panel machine to produce ceilings with punching functions. Through the integrated punching process, the produced ceilings are both beautiful and have good ventilation and sound insulation effects. They are widely used in commercial, industrial and other occasions where perforated ceilings are required.

- Multi-aperture design: KINGREAL metal ceiling perforated production line can customize the aperture size according to customer needs to meet different ceiling decoration effects and functional requirements. It can realize different holes punched out of one production line. Whether it is a small or large aperture design, it can be efficiently produced to meet different engineering needs.

- Multi-ton metal punching machine options: KINGREAL offers two different tonnage metal punching machines, 125 tons and 160 tons. Customers can choose the most suitable punching tonnage according to their actual production needs and raw material characteristics. Through full communication with customers, KINGREAL engineers will provide customers with professional selection suggestions to ensure the efficient operation and optimal performance of the equipment.

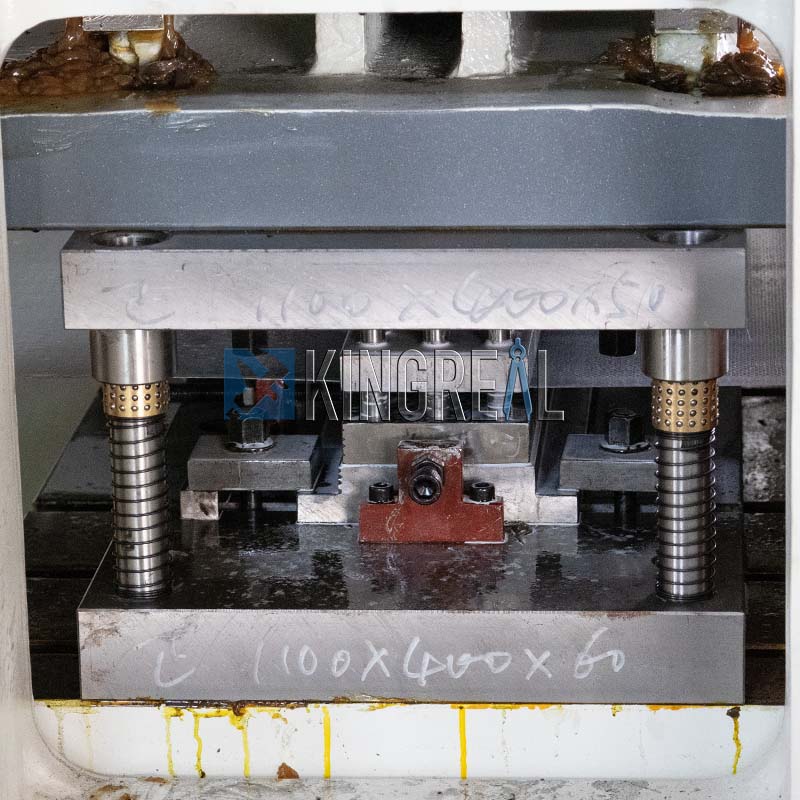

Metal Ceiling Bending Forming Press Machine

Bending is a crucial link in ceiling production. KINGREAL's metal ceiling bending forming press machine has become the first choice of many production companies with its high precision and flexibility. The main features include:

- Multi-function press design: The metal ceiling bending forming press machine can press the four corners of the ceiling at one time to meet the production needs of different plate types. By replacing different molds, various types of ceilings can be produced, such as Clip In, Lay In, Tegular, etc. Mold replacement is simple and efficient, helping customers save production time and reduce equipment investment.

- Purchase press parts separately: If the press parts are damaged in the metal ceiling production line, customers do not need to repurchase the entire production line. KINGREAL offers the service of purchasing press parts separately, which makes equipment maintenance more flexible, reduces equipment downtime, and further reduces maintenance costs.

Perforated Punching Mold

For metal ceiling perforated production lines, perforation punching dies are key supporting equipment. KINGREAL provides a variety of dies to meet the punching requirements of different materials and customer needs:

- Efficient punching: Used in conjunction with the metal punching machine, KINGREAL's dies can punch 8 rows of holes for aluminum plates and 4 rows of holes for iron plates at a time, greatly improving production efficiency. The efficiency of the dies allows customers to complete more production tasks in a shorter time.

- Customized design: According to the customer's production needs and drawings, KINGREAL's engineers can provide customized punching dies. These dies fully meet the customer's specifications and ensure the accuracy of the product.

- Durability and high quality: KINGREAL's punching dies are made of high-quality raw materials and undergo strict quality control and testing to ensure that the dies have high durability and long-term stable service life. Before being put into use, each mold undergoes rigorous trials and precision testing to ensure that it meets high-standard production requirements