KINGREAL CASE : COIL SLITTING LINE

2025-04-24 12:33KINGREAL steel coil slitting machines not only have excellent performance and diverse applications, but also have won the trust of many customers around the world. In order to let you better understand the featured models of KINGREAL steel coil slitting lines and their excellent performance, KINGREAL will share six successful cases below. These cases cover customer feedback from Saudi Arabia, Bangladesh, the United Arab Emirates, Vietnam and other countries, hoping to provide reference for customers with purchasing needs.

1. Mini steel coil slitting line in Brazil

1.1 Features of mini steel coil slitting line

In Brazil, KINGREAL provides customers with a mini steel coil slitting line. This mini steel coil slitting machine is designed for slitting small coils and has the following features:

| Small footprint | suitable for factories with limited space, effectively saving production space |

| Processing of light and thin metal raw materials: | specially designed for processing light and thin materials, especially suitable for small-scale production |

| Budget-friendly | very suitable for customers with low processing output requirements and limited budgets |

1.2 Brazilian customer feedback

Brazilian customers said that after using this specially designed mini steel coil slitting line, they significantly saved coil processing costs.

At the same time, the high efficiency and low energy consumption of the mini steel coil slitting machine make the production process more economical and efficient.

This mini steel coil slitting machine not only meets their production needs, but also improves the flexibility of the entire production line.

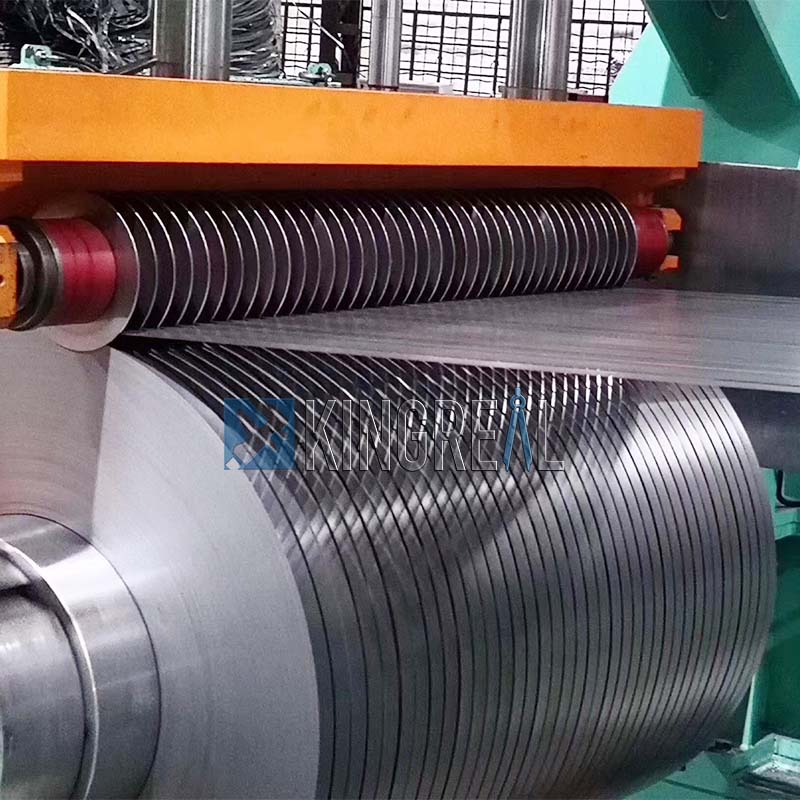

2. Heavy gauge coil slitting machine in the United States

2.1 Features of heavy gauge coil slitting machine

In the United States, KINGREAL provides customers with a heavy gauge coil slitting machine with the ability to handle thick-gauge materials. Its features include:

| Slitting and thick-gauge processing capabilities | can easily handle metal raw materials with a thickness range of 6-16mm, including HR, CR, SS, GI, PPGI and copper |

| Heavy-duty decoiler | equipped with regenerative drive braking function, which improves energy efficiency |

| Precision large knife shaft technology | reduces knife swing and provides consistent blade gap |

| Arc tracking system | reduces material bending and ensures the quality of the finished product |

| Automatic threading function | simplifies the operation from decoiler to recoiler |

2.2 American customer feedback

American customers reported that this heavy gauge coil slitting machine solved their previous problem of not being able to slitting thick plates.

Because the heavy gauge coil slitting machine can handle a wider range of thicknesses, they can slitting plates of various thicknesses more flexibly, greatly improving production capacity and scale.

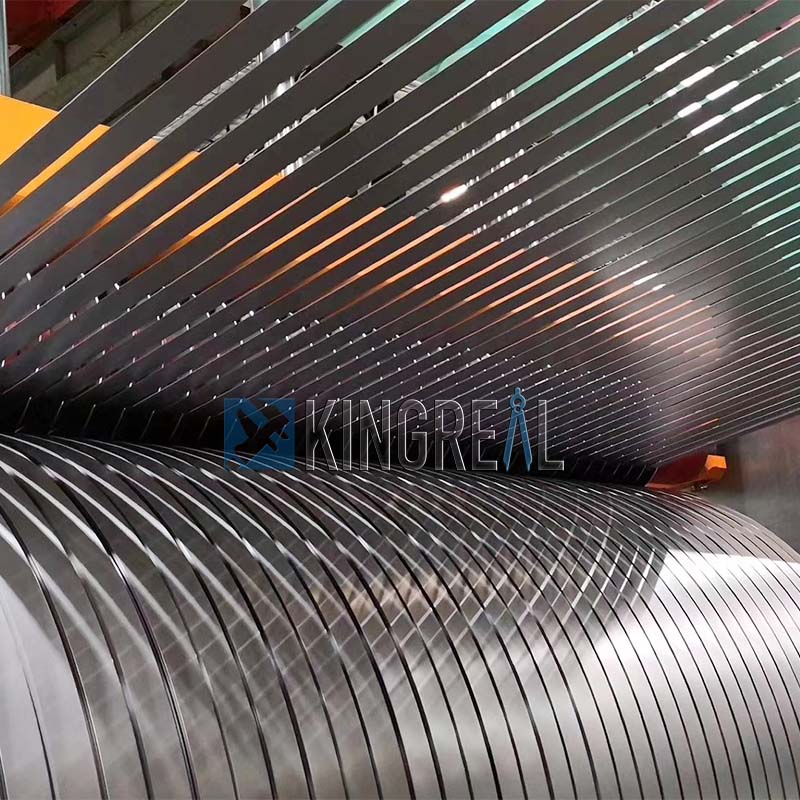

3. High speed steel slitting line in Italy

3.1 Features of high speed steel slitting line

In Italy, KINGREAL installed a high speed steel slitting machine with a production speed of up to 220 M/min. The main features of the high speed steel slitting machine include:

| AC servo motor decoiler | improves unwinding accuracy and speed |

| Electric flattening machine | ensures coil flatness |

| Dual eccentric adjustment slitter | improves slitting flexibility |

| Scrap recoiler with power conveyor | effectively recycles production waste |

| Tension device and adjustable guide roller | ensure uniform tension of the material during processing |

3.2 Italian customer feedback

Italian customers said that the flexibility and efficiency of this high speed steel slitting line have been greatly improved.

While one slitting head is in production, the operator can install knives and pads on the other slitting head, which not only improves work efficiency but also reduces the idle time of the high speed steel slitting line.

This design provides great convenience for large manufacturers who need to slit a large number of coils.

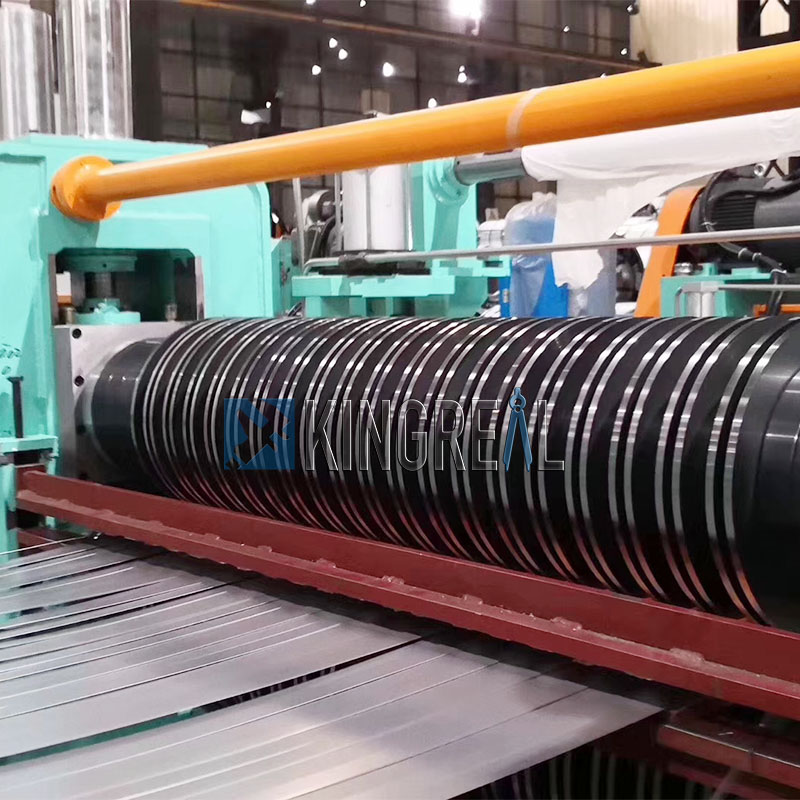

4. 1650mm metal slitter in Indonesia

4.1 Features of 1650mm metal slitter

In Indonesia, KINGREAL provides customers with a 1650mm steel coil slitting machine that can handle a variety of metal coils. Features include:

| Processing width | it can slitting metal raw materials with a width of 300-1650mm |

| Material type | suitable for CR and GI materials |

| Steel thickness | the processing thickness range is 1-4.0mm |

| Coil specifications | supports coils with a variety of inner and outer diameters and weights |

4.2 Indonesian customer feedback

Indonesian customers reported that this 1650mm steel coil slitting machine perfectly meets their needs for slitting metal coils with larger widths and provides more flexibility.

Indonesian customers said that being able to choose the right coil width according to different production needs is crucial to improving production efficiency and flexibility.

5. Silicon Steel Coil Slitting Line in the UAE

5.1 Features of silicon steel coil slitting line

In the UAE, KINGREAL provides a silicon steel coil slitting line dedicated to electrical silicon steel coils. Machine features include:

| DC drive | ensures stability in unwinding and rewinding |

| PLC automatic control | achieves precise control and speed regulation |

| High-quality alloy blades | provide high processing accuracy and ensure product quality |

| Electrical and pneumatic components of internationally renowned brands | ensure the reliability and durability of the steel coil slitting machine |

5.2 UAE customer feedback

UAE customers are satisfied with the adjustable speed function of the steel coil slitting line, believing that this feature enables the speed of the entire production line to run synchronously, thereby improving the overall production efficiency.

UAE customers said that this silicon steel coil slitting line has significantly improved their production capacity and gained an advantage in market competition.

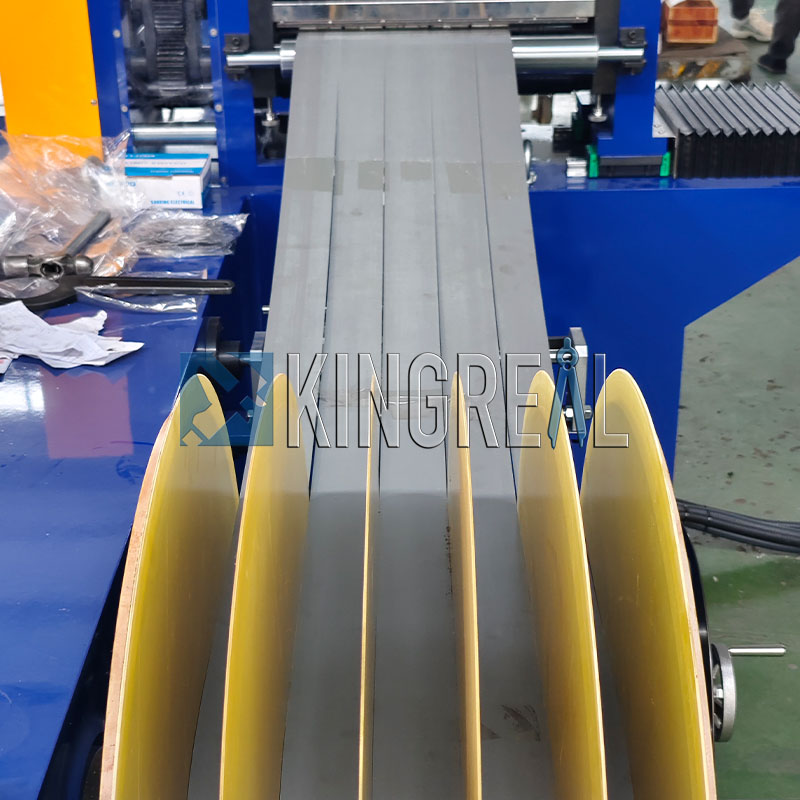

6. Aluminum Slitting Machine in Turkey

6.1 Features of aluminum slitting machine

In Turkey, KINGREAL provides customers with an aluminum slitting machinespecifically for processing aluminum coils. The features of the machine include:

| Material type | mainly processes aluminum coils of various alloys (such as AA1050, AA3003, AA5052) |

| Thickness range | able to process aluminum strips from 0.1 mm to 4.0 mm |

| Width range | able to process aluminum coils with a width of 100 mm to 2000 mm |

| Precision cutting mechanism | ensures that the edges of the aluminum strip produced are clean, without burrs or deformation |

6.2 Turkish customer feedback

The Turkish customer said that the aluminum slitting machine is flexible in customization, and customers can easily adjust the width of the slit strip according to specific requirements.

The precision cutting mechanism ensures that even minor defects will not affect the performance and durability of the final product, which is crucial in the aluminum processing industry.