Metal Perforated Making Machine To Turkey

2024-11-08 14:41KINGREAL Metal Perforated Making Machine To Turkey

KINGREAL MACHINERY manufacturing the metal perforated making machine for Turkey customer. The metal peroforated making machine is used for produce high precision perforated sheet by the punch press machine, according to our Turkey customer needing, KINGREAL MACHINERY design the new metal perforated making machine with cutting station.

Features of KINGREAL sheet metal punching machine

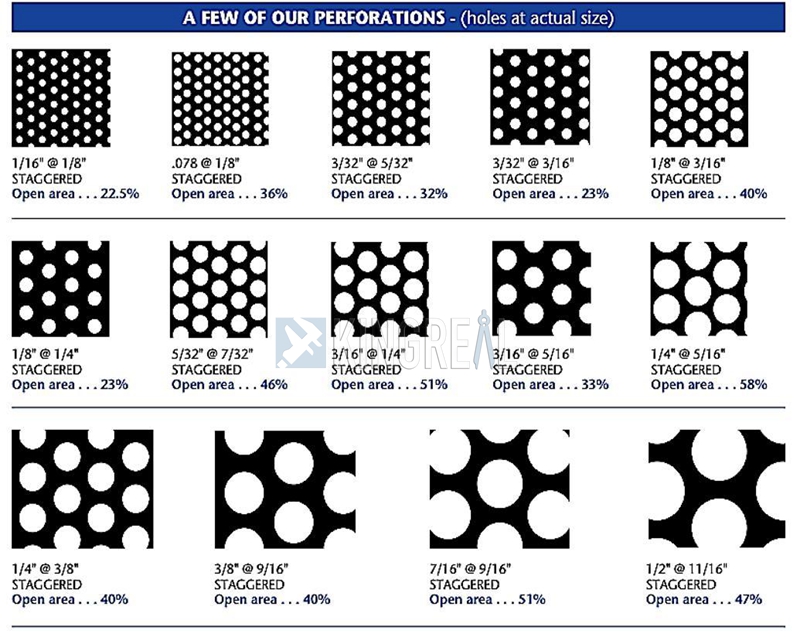

1. Diverse punching patterns

KINGREAL's metal perforating machine can provide customers with the production capacity of various hole types by replacing different punching dies. Common hole types include round holes, square holes, long holes, mesh holes, etc.

In addition, KINGREAL can also customize more special hole types according to customer needs. This design enables customers to flexibly respond to different production tasks and improve the versatility and adaptability of the perforated metal machine.

2. High-speed punching performance

KINGREAL's metal punching machine adopts advanced punching technology and optimized process flow, and can provide different punching speeds according to customer production needs. Whether it is mass production or fine processing, KINGREAL can flexibly adjust according to customer needs to ensure high efficiency while ensuring the accuracy and quality of the holes.

3. Fully automated system

KINGREAL's sheet metal perforating machine integrates automated facilities such as hydraulic decoiler, precision straightener, punching machine, shearing station, etc., to maximize the full automation of the metal punching machine. The automated design reduces manual intervention, which not only improves production efficiency but also reduces production costs. At the same time, the high intelligence of the system can also reduce human errors and ensure production stability and consistency.

4. Customized solutions

KINGREAL is known for its excellent customization capabilities. According to the specific needs of customers, engineers will tailor the design of the metal perforating machine according to the required raw materials, thickness, punching speed and other factors. Each customer has different production needs and process requirements. KINGREAL's customized solutions ensure that customers get the most suitable equipment configuration to achieve the best production results and maximize investment returns.

Professional services provided by KINGREAL to Turkish customer

1. Factory visit service

KINGREAL provides factory visit services and arranges professional technicians to accompany customers to visit the factory, and introduces in detail the working principle of the perforated metal machine, the functions of each key component and its operation method. Customers can not only observe the operation of the equipment up close, but also operate the machine in person, experience the performance and advantages of the equipment, and help customers make more comprehensive judgments.

2. Detailed plan discussion in the conference room

After having a basic understanding of the equipment, KINGREAL's engineers will communicate in depth with customers to understand their specific needs. Including the thickness of the raw materials, the required punching pattern, the target production speed, the specific application areas of the materials, etc. By fully analyzing customer needs, KINGREAL engineers will tailor a sheet metal punching machine solution that best meets their production needs for customers, ensuring that each device is mass-produced according to the customer's special requirements, avoiding a one-size-fits-all standardized solution.

3. After-sales installation and training services

After the metal perforating machine is completed, KINGREAL will send professional engineers to the customer's factory for on-site installation and commissioning to ensure that the equipment can be put into production smoothly. At the same time, KINGREAL also provides customers with operation training to help customers' workers master the correct operation methods of the equipment and reduce possible misoperations in production.

In addition, KINGREAL will also explain to workers in advance the problems that may be encountered during daily use and their solutions to ensure that customers can use the equipment efficiently and stably to avoid production interruptions or equipment failures.