Advantages of light gauge steel framing

2024-09-12 17:32Light steel villa frames are manufactured by light steel frame machines through uncoiling, forming, punching, cutting and other processes. Common light steel frames include C profile, with sizes of C75mm, C89mm, C140 (150) mm, and Top Hat with sizes of 51 mm and 76 mm. Light steel villas are becoming more and more popular, so what are their advantages? The following KINGREAL will introduce the features of light steel villa, hope it can help you know more about light steel villas.

Advantages of light steel villa

The advantages of light steel villa are as follows:

1.Thermal insulation

Light steel villa adopts energy-saving system, filling glass wool as thermal insulation material in the wall keel grid, and using extruded polystyrene thermal insulation board or polyurethane thermal insulation material in the outer wall, avoiding the phenomenon of "cold bridge" in the wall.

2. Sound insulation

Light steel villa consists of light steel keel, sound insulation material composed of wall, floor and roof system, its sound insulation effect is very good. KINGREAL Light Gauge Steel Framing Forming Machine is designed for producing steel structure light steel villa house with high speed. It is the best choice for light steel villa production.

3.Comfort

The light steel wall can adjust the humidity of indoor air; the roof has the function of ventilation, which can form a healthy air circulation space over the interior of the roof to ensure the ventilation and heat dissipation needs of the residence.

4.Durability

The structural components of light steel structure villa are built with high-strength aluminium-plated zinc light steel keel, which effectively avoids the rusting of steel components in the process of use and has a long service life.

5.Anti-seismic

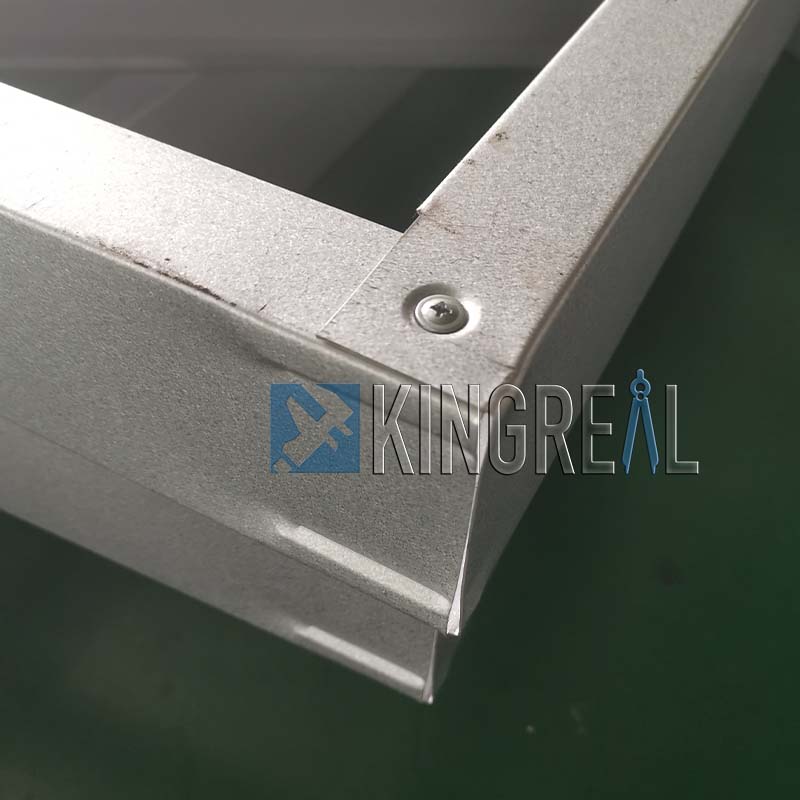

Light steel villa house adopts advanced light steel main structure, its structural keel and internal maintenance materials using galvanised self-tapping screws tightly connected, between the keel using a large number of seismic connectors, reinforced to form a very strong "plate rib structural system", this structural system has a stronger seismic and resistance to horizontal load capacity, suitable for earthquake intensity This structural system has a stronger ability to resist earthquakes and horizontal loads, and is suitable for areas with higher seismic intensity.

6. Resistance to wind and snow

The light steel building structure of assembled light steel house has good overall performance and high strength of components, which can withstand larger snow pressure and resist stronger hurricane winds, so that the whole building system can be effectively guaranteed.

7.Anti-insects and ants

The use of aluminium-zinc-plated steel, both anti-corrosion, but also not subject to the invasion of termites and other insect pests, to improve the service life of the house and reduce maintenance costs.

8.Fast construction speed

The construction of light steel villa is highly industrialised and fast, which greatly shortens the construction cycle compared with traditional construction.

9. Wide scope of application

The building load-bearing system of light steel villa adopts light steel structure, its own weight is light, suitable for building in all kinds of geological conditions foundations and 5-storey building, can greatly reduce the cost of foundation construction, standardised residential system construction operations by the weather and seasonal influence less, and can be factory production and on-site installation in parallel, can be in a variety of climatic conditions, to achieve the year-round uninterrupted construction. Widely used in private villas, new rural construction, resettlement houses, libraries, office buildings, schools, hospitals, and other places. With the rise of demand, there are more and more light steel keel villa manufacturers to buy Kingreal Light Gauge Steel Roll Forming Machine to improve production speed. If you have a requirement to upgrade your production, please do not hesitate to contact us!

Market demand of light gauge steel framing

As a new type of building form, light steel villas have been widely used around the world in recent years due to their superior performance and flexible design. Light steel structure villas not only have the advantages of earthquake resistance, wind resistance, and corrosion resistance, but also can effectively shorten the construction period and reduce construction costs. Therefore, more and more countries and regions have begun to pay attention to and adopt light steel villas. The following are some countries and regions with a large demand for light steel villas, and the reasons behind them.

1. United States

The United States is an important market for the application of light steel villas, especially in the west and south. In recent years, due to frequent natural disasters (such as earthquakes and hurricanes), people have put forward higher requirements for the earthquake resistance and wind resistance of houses. Light steel villas have performed well in these aspects and have become the first choice for many families. In addition, the building regulations in the United States have strong support for green buildings and sustainable development, and the environmental protection characteristics and high energy efficiency of light steel villas are also in line with this trend.

2. Canada

In Canada, light steel villas have gradually become an emerging residential choice, especially in cities such as Vancouver and Toronto. Due to Canada's cold climate, the superior thermal insulation performance and structural strength of light steel villas enable them to effectively withstand severe cold weather. In addition, the Canadian government's advocacy and support policies for green buildings have promoted the promotion of light steel villas, and many developers have begun to invest in this form of construction.

3. Australia

The Australian construction market has also shown great interest in light steel villas. As the country is located in an earthquake zone, the seismic performance of light steel structures is valued. At the same time, Australia's construction policy encourages the use of renewable materials and energy-saving technologies, and light steel villas just meet this demand. In addition, Australia's land resources are relatively tight, and light steel villas can be flexibly designed to maximize the use of space, which is also one of the reasons for its popularity.

4. New Zealand

New Zealand is also an important market for light steel villas. The country has frequent earthquakes, and the fragility of traditional building forms has prompted people to turn to safer building solutions. Light steel villas are earthquake-resistant and fast to construct, and can quickly provide safe living space in an emergency. The New Zealand government is also actively promoting light steel buildings to meet the challenges brought by natural disasters.

5.. Japan

Japan is a country with frequent natural disasters, especially earthquakes. Light steel villas are increasingly favored by the Japanese market due to their excellent earthquake resistance. Japan has strict building regulations. While light steel villas meet safety standards, they can also provide diversified designs to meet the needs of different users. In addition, with the increase in environmental awareness, the green building characteristics of light steel villas have also provided impetus for their promotion in the Japanese market.

Video about lgsf machine

Main components of light steel frame machine

Light gauge steel machine is an efficient building material production equipment. Its main components have unique functions and work together to achieve high-quality light steel structure products.

1. Decoiler

The decoiler is used to unwind the coiled metal material and supply it for subsequent processing. This component ensures the flatness and stability of the material, laying a good foundation for subsequent forming.

2. Roll forming machine

The forming host is the core component of the light gauge steel framing machine, which is responsible for forming the metal material into the required light steel structure shape through multiple rolls. The equipment adopts high-precision forming technology to ensure the dimensional consistency and high strength characteristics of the final product.

3. Automatic punching station

The automatic punching station is used to perform precise punching processing on metal materials to meet design requirements. This component has a high degree of automation and can complete punching quickly and efficiently, ensuring the accuracy of the position and size of the hole, which is convenient for subsequent assembly and connection.

4. Cutting station

The cutting station is responsible for accurately cutting the formed metal components according to the preset length. This component is equipped with high-precision shearing equipment to ensure neat and accurate cutting in light gauge steel machine with the specific needs of customers.

The coordinated work of these components makes the light gauge steel framing machine efficient, precise and flexible in the production of light steel structures, meeting the market's growing demand for building materials.