- Home

- >

- News

- >

- Case: Cut to Length Line

- >

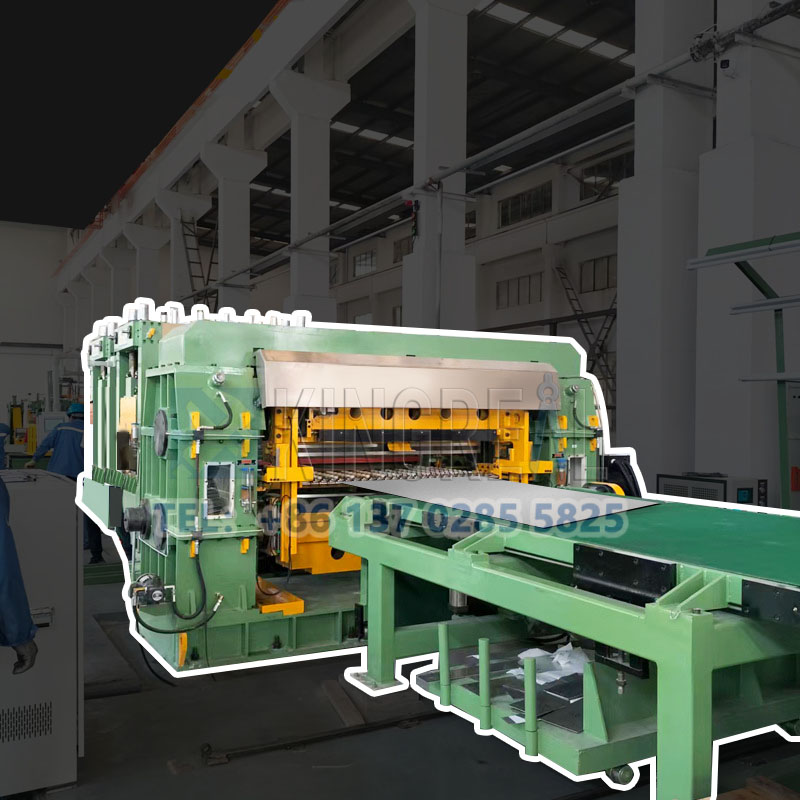

Case: Cut to Length Line

2024-12-12 11:15

KINGREAL is a manufacturer that has been deeply involved in the cut to length line manufacturing field for more than 20 years. It has sold more than 200 cut to length machines and has reached friendly cooperation with customers in 50 different countries. These include India, the Philippines, Russia, Australia, the United States, the United Kingdom and other countries.

KINGREAL's cut to length line is widely praised by customers, and is praised for its good machine quality and fast shearing speed, which greatly improves the work efficiency of the factory.

Advantages of cut to length line

① Automation cut to length line.

KINGREAL metal cut to length line adopts an automated mode, which can achieve continuous and rapid cutting of metal plates, greatly improving production efficiency. Compared with traditional manual operation, the shearing line can complete the precise shearing of a large number of plates in a short time, meeting the needs of modern industry for efficient production.

② High precision metal cut to length machine.

KINGREAL metal cut to length line is equipped with advanced control systems and precision tools to ensure that each cutting meets extremely high precision requirements. High-precision metal plates can better carry out the next process.

③Strong flexibility for metal cut to length machine.

KINGREAL cut to length machine supports the processing of metal plates of various specifications and materials, such as cold-rolled steel coils, hot-rolled carbon steel coils, stainless steel coils, copper, aluminum, etc., and can provide different types of machines to adapt to coils of different thicknesses. This flexibility enables the cut to length line to be widely used in many fields such as automobiles, aerospace, and construction.

④Save materials and costs.

KINGREAL metal cut to length line can accurately calculate and control through an intelligent control panel, which can maximize the use of raw materials and reduce waste generation. At the same time, automated operations reduce dependence on labor and reduce labor costs.

KINGREAL's special cut to length line

① Heavy gauge cut to length line. It can process thick metal raw materials (6-20mm) with a time of 8-12pcs/min.

② Fly shearing cut to length line.Flying shearing means that there is no need to stop feeding during the shearing process, and the shearing length and feeding speed can be freely modified during the processing process, so the processing efficiency of steel plate and aluminum strip shearing is greatly improved.

③ Simple cut to length line.The three-in-one cut to length machine integrates the three processes of uncoiling, leveling and cutting, realizing the integrated production from coils to finished plates, greatly shortening the production cycle. And because the entire production process is completed on one line, the material transfer and waiting time are reduced, thereby improving production efficiency.

Heavy gauge cut to length line

Fly shearing cut to length line

Simple cut to length line

Video About Metal Cut to Length Line

Why choose KINGREAL?

① Perfect service experience. KINGREAL not only invites customers to visit the factory and observe the operation of the machine on site, but also communicates with customers in depth to fully understand the production needs of customers. Based on this detailed information, KINGREAL can tailor a perfect solution for customers. When the metal cut to length machine is produced, KINGREAL will send experienced engineers to the customer's factory to conduct machine installation and operation training to ensure that customers can get started smoothly and use it efficiently.

② Quality assurance. KINGREAL's machines have passed strict certification to ensure the compliance and reliability of the products. What is more worth mentioning is that each machine will undergo a strict start-up test after it is produced. During the test, the machine will be put into the metal raw materials for actual operation. Only qualified machines that pass this link will be carefully packaged and sent to the customer's factory.

③ As a cut to length line manufacturer with more than 20 years of experience, KINGREAL has a deep understanding of the research on shearing lines. At the same time, KINGREAL is also well aware of the differences in machine requirements and parameters in different countries. Therefore, KINGREAL can flexibly adjust and optimize the machine according to the specific needs of customers, targeting different countries and different application scenarios.