Cooperation with India Customer Ceiling Channel Machine

2024-10-15 16:54False Ceiling Machine Shipped to India

Based on our customer’s trust in the quality of KINGREAL machines, we carried out a smooth communication, and finally the customer placed an order for the Wall Angle Making Machine with us.

After ordered, KINGREAL technical team test the machine at once, insure every mechanical and electrical parts are in perfect condition, is our promise also what we do as always. Now the Wall Angle Making Machine was successfully shipped to India!

Advantages of False Ceiling Channel Machine

In the field of modern construction and interior decoration, false ceiling channel, as an important structural material, is favored for its lightness, durability and easy installation. In order to meet the market demand for efficient and high-quality false ceiling channels, KINGREAL has developed and produced a series of advanced wall angle channel making machines. These models have many advantages in design and function, providing customers with an excellent production experience. The following will introduce the main advantages of KINGREAL wall angle making machine in detail.

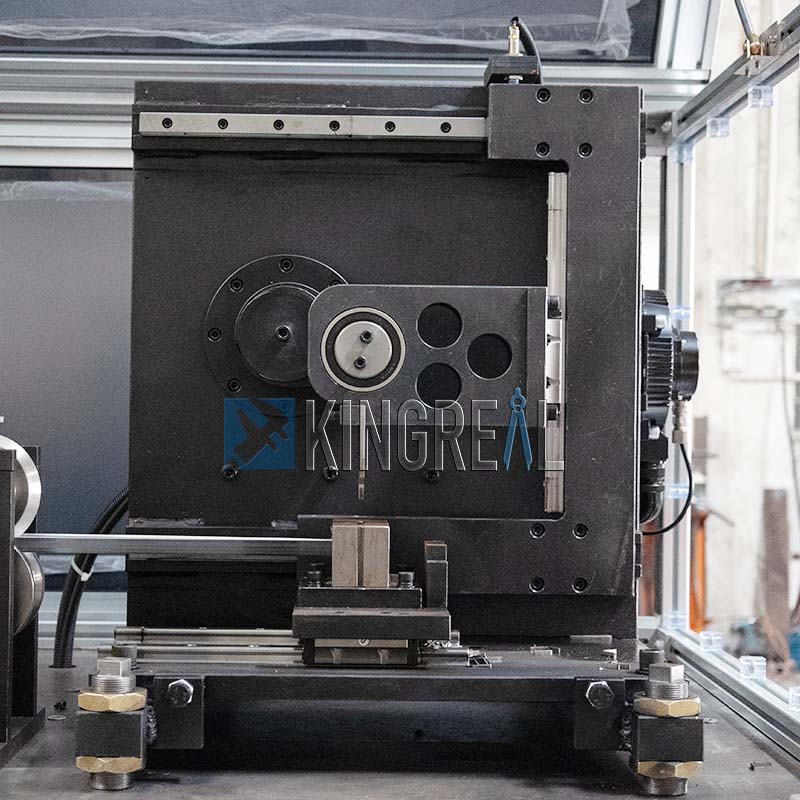

Protective shield

In industrial production, safety is always the primary consideration. KINGREAL knows this well, so it has equipped the false ceiling channel machine with a protective shield. This protective shield is designed to reduce potential safety hazards during work and ensure the safety of operators. In addition, the protective shield can also keep the factory workshop clean and tidy, and avoid metal chips and other debris from polluting the working environment.

In many countries, there are strict laws and regulations for the safety of mechanical equipment. KINGREAL's protective shield meets relevant standards and can effectively reduce the probability of accidents. This is not only responsible for the safety of employees' lives, but also a reflection of the company's social and environmental responsibilities. Through such a design, KINGREAL provides customers with a safe and reliable production environment and enhances customers' confidence in the wall angle channel making machine.

Swing shear system

The shearing station of the wall angle making machine is equipped with an advanced swing shear system, which greatly improves production efficiency. Traditional shearing methods often require stopping for adjustment, while the swing shear system allows the machine to cut during operation, and customers can accurately cut according to the preset length. This means that there is no need to stop during the production process, reducing the downtime in production and significantly improving production efficiency.

Another significant advantage of the swing shear system is its accuracy. Since the system can adjust the shearing position in real time, it ensures that each section of false ceiling channel can meet the size required by the customer. This is especially important for customers who need to produce in large quantities, which can ensure the consistency and accuracy of the product in specifications and meet the strict requirements of the market.

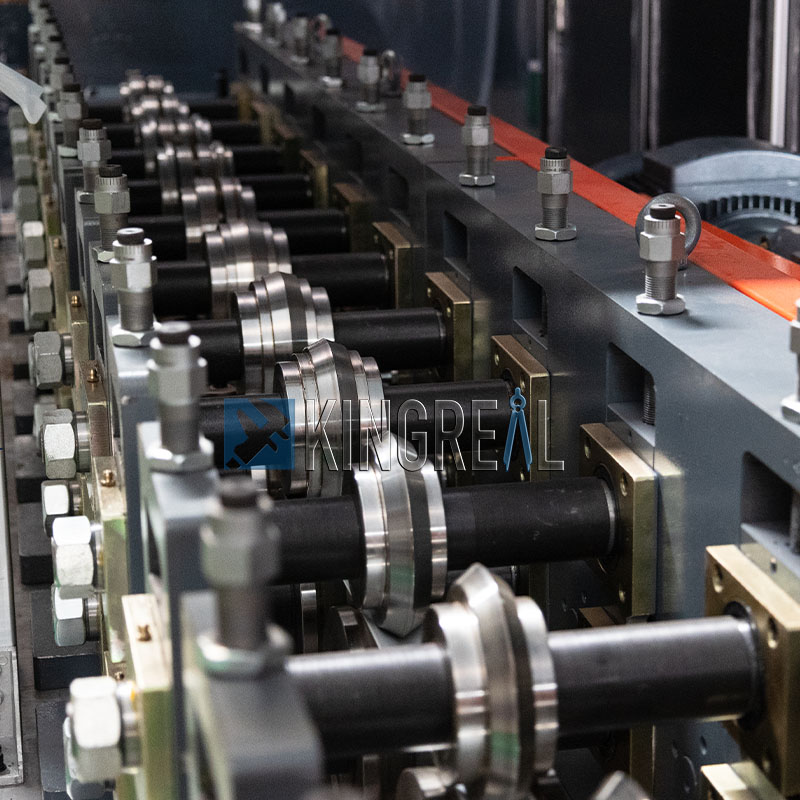

High-quality rollers

KINGREAL false ceiling channel machine uses high-hardness rollers, which are not only durable, but also provide better forming effects during the forming process. The use of high-hardness rollers ensures that the long production process will not cause equipment wear, thereby extending the service life of the machine.

During the forming process of light steel keels, the quality of the rollers directly affects the precision and appearance of the finished product. KINGREAL's rollers are precisely designed and manufactured to maintain stable performance under different production conditions, ensuring that the produced false ceiling channels have excellent surface smoothness and consistent shape. This is crucial for customers to reduce the difficulty of installation and improve the aesthetics of the finished product in subsequent assembly and use.

Independent archway

In order to improve the overall operating stability of the wall angle making machine, KINGREAL has equipped the roll forming machine with an independent archway. The design of the independent archway not only improves the durability of the machine, but also enhances the smooth operation performance of the equipment under high-load operation. This design concept fully considers the complexity of the production environment and can effectively cope with various external shocks and load changes.

During the production process, the stability of the independent archway makes the false ceiling channel more uniform during the forming process, reducing product quality problems caused by equipment vibration. For customers, this means that product quality can be consistent over a long period of production, thereby reducing the pressure of after-sales service and improving brand reputation.

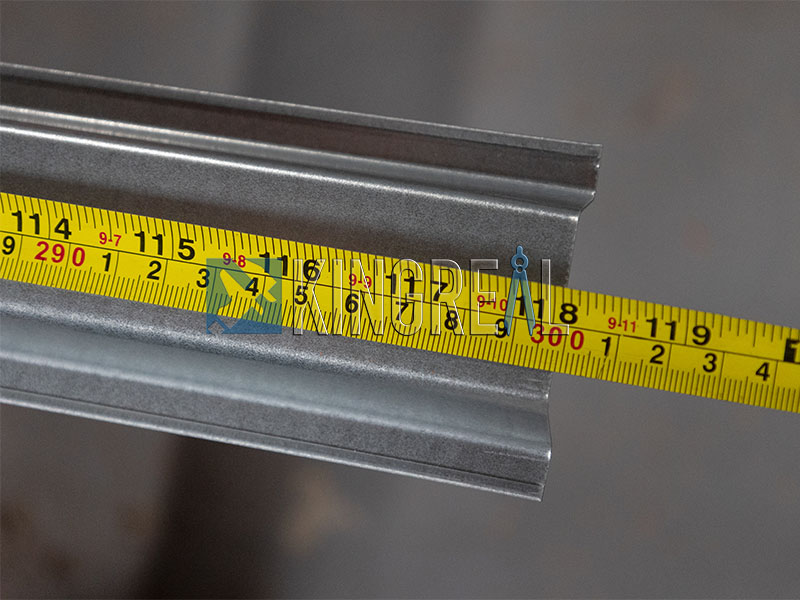

High-precision Finished Product

One of the biggest advantages of KINGREAL wall angle making machine is that it can produce high-precision finished products. After the machine is manufactured, KINGREAL will conduct a strict test to ensure that each device can meet the design standards. During this process, the staff will conduct a comprehensive test on the produced false ceiling channel to check whether its size and shape meet the customer's production requirements.

Especially under the same parameter conditions, whether the machine can produce consistent wall angle making machines is an important indicator for testing equipment performance. KINGREAL not only pays attention to the quality of single production, but also pays more attention to the consistency of products after long-term operation, which has a direct impact on the customer's production efficiency and product quality.

Through a strict testing process, KINGREAL ensures that each false ceiling channel machine undergoes rigorous quality inspection before being delivered to customers. This strict control of quality allows customers to be more assured when using KINGREAL's equipment, improving the stability and reliability of production.

Why Choose KINGREAL?

As a professional manufacturer of metalworking equipment manufacturer in China, in particular Roll Forming Machine, technology is always the capital we are proud of. We have accumulated many successful cases: light steel keel roll forming machine, T grid roll forming machine, roof tile roll forming machine and so on.

KINGREAL has established a strict quality control process to ensure that every production step meets the standards and requirements. This includes raw material procurement, production process, assembly, testing, etc. To ensure that every part of the machine meets quality standards. We has also passed the international CE certificate certification.

In order to provide better service to customers around the world, in addition to establishing a complete remote service system, localized after-sales service is also what we have been insisting on doing. We treasure every opportunity to communicate with each and every one of you! Welcome to communicate with us!