How to use Linear Strip Ceiling Carrier Machine?

2025-01-28 14:34Definition of Linear Strip Ceiling Carrier Machine

Linear Strip Ceiling Carrier Machine is a highly efficient and automated equipment designed for the production of metal linear strip ceiling carriers. It can process metal coils into carriers for ceiling systems through a series of precise mechanical processes. In addition, KINGREAL also has a professional roll forming machine that can produce baffle ceiling carriers - baffle ceiling carrier machine.

As a professional manufacturer, KINGREAL can customize production lines according to customer needs to meet the production needs of ceiling carriers of different specifications, sizes and uses. This ceiling carrier production line is popular with customers for its simple operation, high production efficiency, high forming accuracy and reasonable price. In addition, KINGREAL also provides linear strip ceiling machines and baffle ceiling machines, which can be used with ceiling carrier machines to achieve a complete metal ceiling solution.

Main Components of Linear Strip Ceiling Carrier Machine

1. 2-in-1 Decoiler & Straightener for linear strip ceiling carrier machine - Function: Responsible for uncoiling and leveling the metal coils to ensure that the surface of the material is flat and wrinkle-free before entering the ceiling carrier production line. - Features: Uncoiling and leveling integrated design, saving space and improving efficiency.

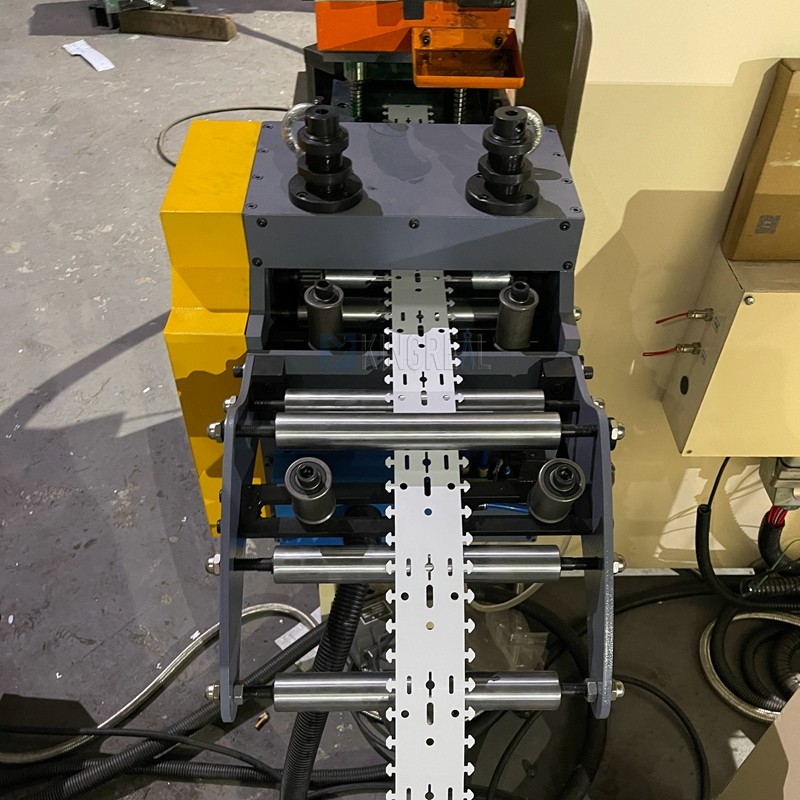

2. Metal Punching Machine for linear strip ceiling carrier machine - Function: Perform preliminary processing on metal materials, including embossing, punching and other processes. - Features: High precision, able to adjust the pressing parameters according to different design requirements.

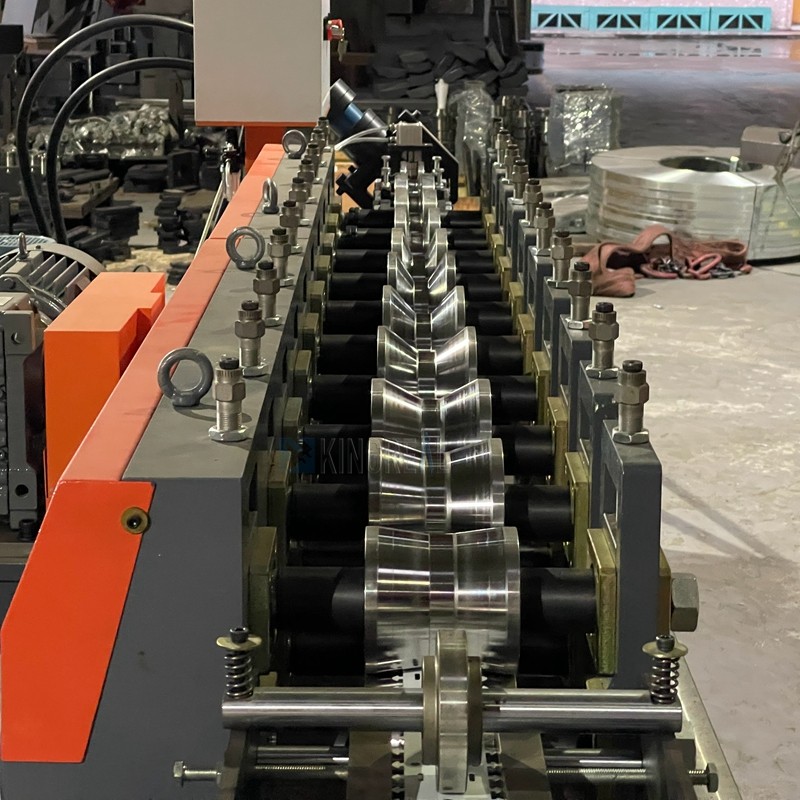

3. Main Roll Forming Machine for linear strip ceiling carrier machine - Function: Core component, through a series of rollers to process metal materials into a specified shape of the card bone product. - Features: High flexibility, adjustable to adapt to different specifications of products.

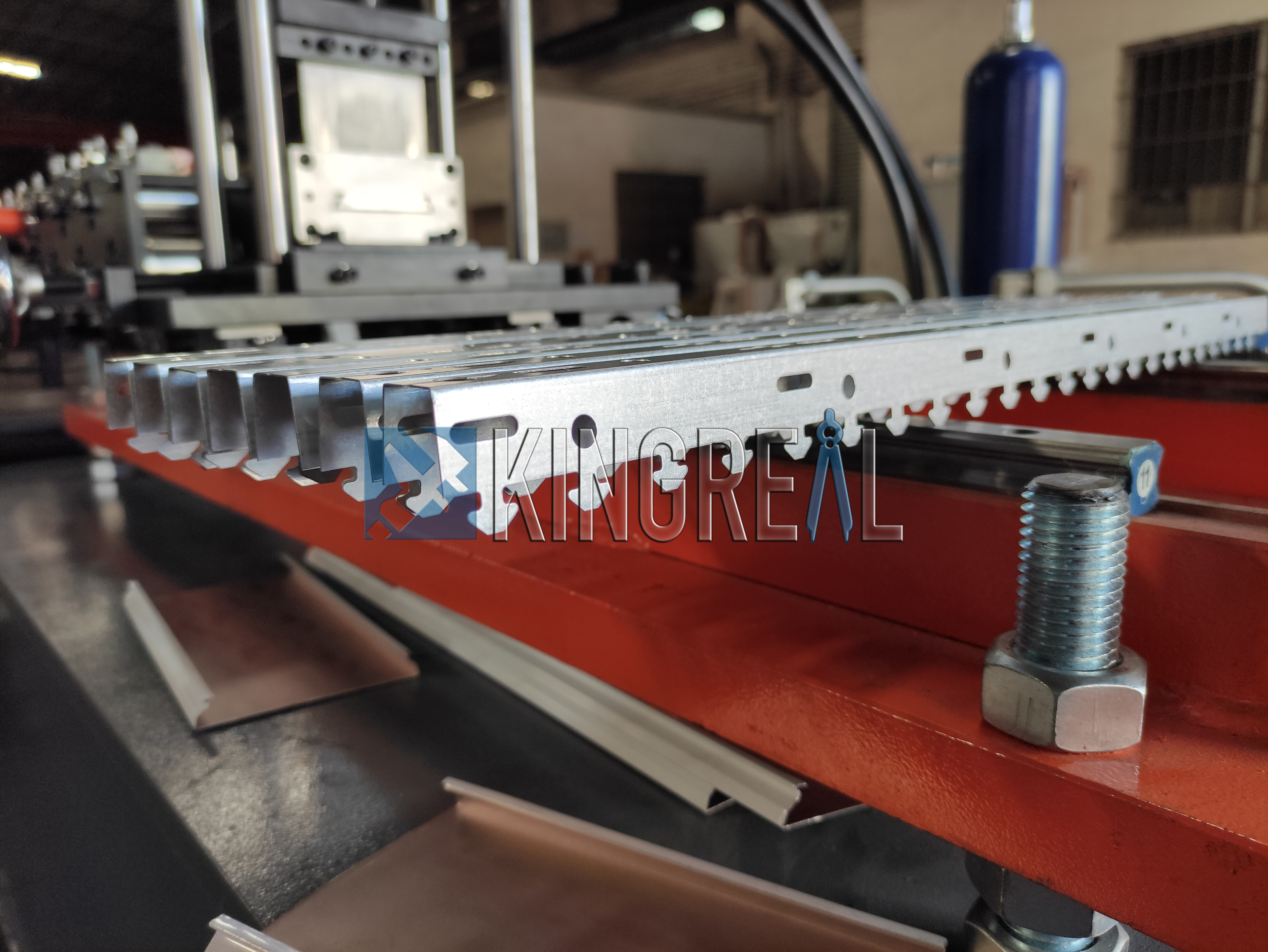

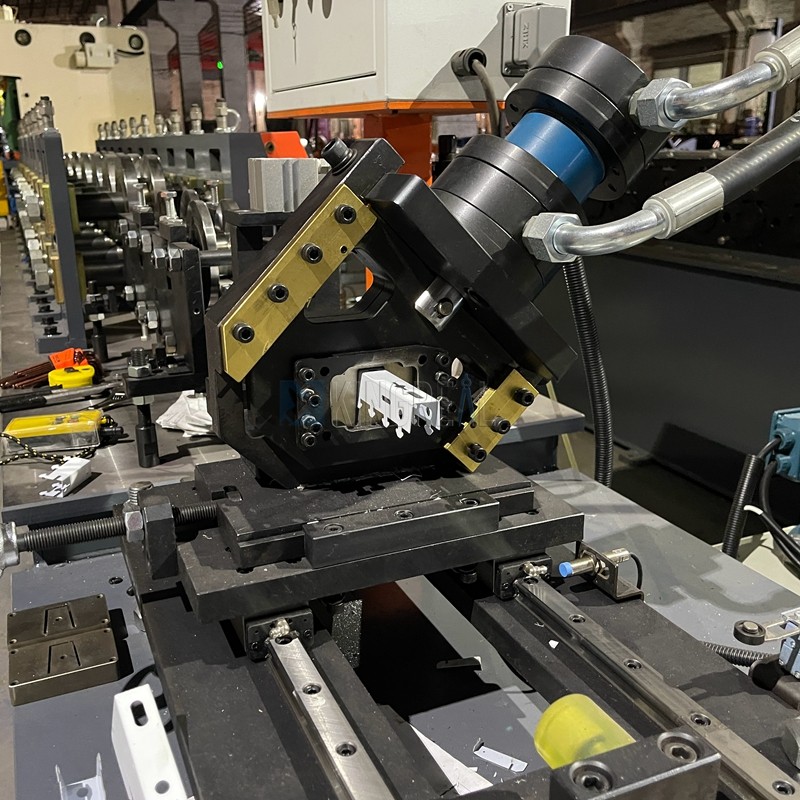

4. Shearing System for linear strip ceiling carrier machine - Function: Cut the formed metal card bone into a specified length. - Features: High-speed cutting, neat cut without burrs, ensuring the precise size of the finished product. |  |

Video About Linear Strip Ceiling Carrier Machine

Correct way to use Linear Strip Ceiling Carrier Machine

Preparation

1. Check the equipment status

- Make sure the linear strip ceiling carrier machine is in normal working condition and check whether all parts are intact, including rollers, shearing system and control system.

- Check the lubrication system to ensure that all moving parts are properly lubricated.

2. Prepare raw materials

- Select metal coils that meet production requirements, usually galvanized steel, stainless steel or aluminum.

- Adjust the width and thickness of the coil according to production specifications.

3. Adjust machine parameters

- Set the equipment parameters according to production requirements, including forming specifications, cutting length and punching position.

- Enter relevant data on the control panel to ensure that the parameter settings are accurate.

Operation steps

1. Loading metal coils

- Use a forklift or lifting equipment to place the metal coil on the decoiler and leveling machine.

- Adjust the clamping device of the decoiler to ensure that the coil is firmly fixed and will not slip during the unwinding process.

2. Manual feeding

- Manually introduce the front end of the metal coil into the leveling machine, start the leveling function, and ensure that the surface of the material is flat.

- Feed the leveled material into the entrance of the main roll forming machine, and adjust the guide device to ensure that the material enters the correct track.

3. Start automatic production

- Start the automatic operation mode on the control panel, and the equipment will automatically complete the unwinding, leveling, forming and cutting processes according to the set parameters.

- During the production process, the operator only needs to monitor the operation of the ceiling carrier machine to ensure that there are no abnormalities.

4. Product collection

- The formed card bone products are output from the cutting system and automatically stacked in the collection area.

- The operator can classify and package the finished products according to needs.