Stud and track machine shipped to India

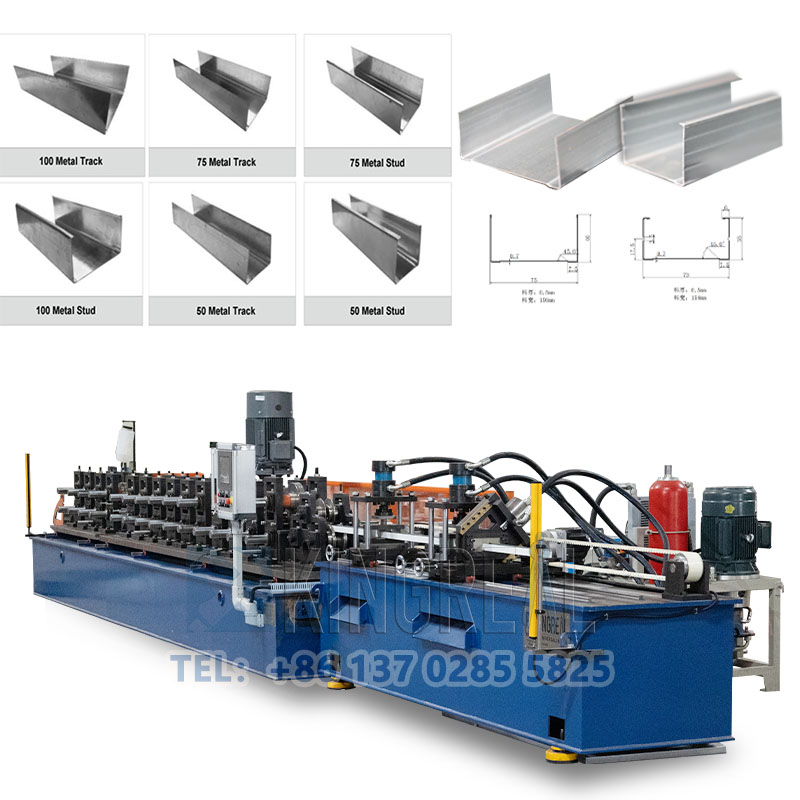

2024-12-04 17:34Recently, KINGREAL's technical team has conducted rigorous testing on the newly produced machine -- stud and track roll forming machine. By putting in metal raw materials and letting the gypsum channel machine operate, the machine operation and the quality of the finished product meet customer requirements. KINGREAL's stud and track roll forming machine has passed the inspection smoothly and has now been successfully sent to the Indian customer factory!

Thanks to the trust of Indian customers, KINGREAL's stud and track roll forming machines have been sold to India, Russia, Spain, the United Kingdom and other countries, and have rich experience in machine manufacturing. And KINGREAL adheres to the principle of continuous learning and innovation. In order to better meet customer needs and improve production efficiency, it has designed a 100m/min high-speed stud and track roll forming machine. In order to better liberate manpower, KINGREAL has also designed an automatic packaging machine that can be used with the gypsum channel machine for automated profile packaging.

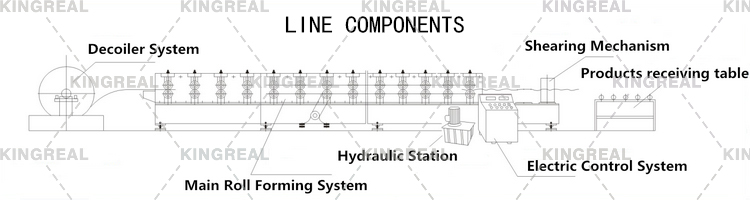

KINGREAL's gypsum channel machine uses metal sheets as raw materials and can produce drywall studs and tracks of different sizes. The gypsum channel machine is mainly composed of hydraulic decoiler, main roller forming machine, shearing system and other components.

Workflow of stud and track roll forming machine

Unwinding-forming-flying punching and flying shearing-discharging

Advantages of stud and track roll forming machine

1.Automatic packing machine

In order to maximize production efficiency, KINGREAL's stud and track roll forming machine can be equipped with an automatic packing machine. It saves you the trouble of manually packing drywall studs and tracks. It not only reduces the manpower generated by manual packing, but also improves production efficiency.

2. Fly punch and shear

KINGREAL's stud and track roll forming machine is equipped with an advanced flying punch and shear station, which ensures that the machine can complete precise cutting without stopping at high speed, greatly improving production efficiency. This uninterrupted processing method significantly saves production time and is particularly suitable for the efficient processing of large-volume orders. At the same time, the flying punch and shear technology can also ensure neat cutting edges, improve product quality, and make your production more efficient and leaner.

3. Intelligent PLC control system

KINGREAL's stud and track roll forming machine is equipped with an intelligent PLC control system. You only need to simply enter the length, width and production quantity of the drywall studs and tracks on the computer interface to start the fully automatic production process. You can flexibly switch product specifications by adjusting the input parameters without frequently changing molds. The intelligent system is not only easy to operate and reduce manual intervention, but also can achieve precise control to ensure that the size of each stud and track meets the requirements.

4. High speed

KINGREAL's stud and track roll forming machine is known for its high-speed production, with a production speed of up to 100 meters/minute, which is suitable for large-scale industrial production needs. If you have a need for higher-speed equipment, we welcome you to consult KINGREAL at any time. Our team of experienced engineers will communicate with you in depth, fully understand your production needs, and tailor a higher performance production equipment solution.

About KINGREAL

KINGREAL is a professional gypsum channel machine manufacturer with rich experience in this industry. And KINGREAL can provide you with strong technical support and 24-hour online service. If you are interested in the gypsum channel machine, you are welcome to give the drawings to KINGREAL, and KINGREAL will definitely make a satisfactory exclusive customized solution for you.