What's advantages of partition frame wall machine?

2025-02-26 12:00The partition frame wall making machine is a featured product of KINGREAL, designed to meet the needs of the modern construction industry. With the growing demand for building materials, the partition frame wall production line has been widely used in many countries around the world, including Canada, Russia, Saudi Arabia, India and Turkey, due to its efficient production capacity and superior product quality. This article will explore in detail the advantages of the partition frame wall machine and its importance in the market.

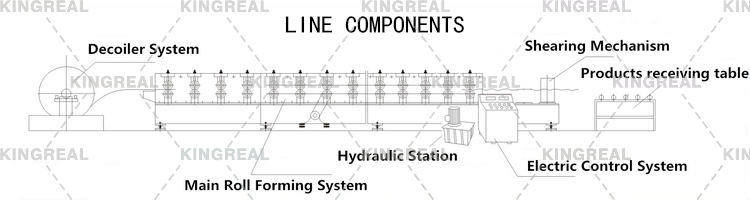

Working principle of partition frame wall production line

The partition frame wall making machine is mainly used to produce partition frame wall, and the raw materials used are usually galvanized sheets. It plays an important role in movable partition walls, especially suitable for places that require flexible space layout. Commonly used in open offices, exhibition halls, conference rooms, etc. Its workflow includes several key steps: unwinding, forming, flying punching and flying shearing, etc. This series of operations is not only efficient, but also can ensure the consistency and quality of the product.

Features of partition frame wall making machine

Cooling system

For high temperature areas such as the Middle East, KINGREAL has equipped the motor with an additional cooling system. This design effectively reduces the failure rate of the machine in high temperature environments and ensures the stable operation of the equipment.

High return on investment

The partition frame wall production line has a fast production speed and low maintenance cost, which can bring customers a considerable return on investment. Customers can recover their investment in a short time through fast production cycles and cost-effective operating costs.

High quality

KINGREAL strictly controls the manufacturing materials of the partition frame wall making machine. The rollers are made of Cr12Mov material and the electrical components are well-known brands, which ensures the durability and stability of the partition frame wall machine.

Advantages of partition frame wall making machine

Fast production speed

The light duty partition frame wall machine can handle metal raw materials with a thickness of 0.35-0.9mm, and the production speed can reach 50-60 m/min. The heavy duty partition frame wall machine can handle materials with a thickness of 0.8-1.2mm, and the production speed is as high as 60-80 m/min. This efficient production capacity enables customers to complete mass production in a short time to meet market demand. Specifically, the fast production rhythm not only shortens the production cycle, but also enables customers to respond to market changes in a short time and quickly adjust production plans.

Multi-specification production capacity

KINGREAL partition frame wall production line can easily realize the production of multi-specification partition frame walls by adjusting the roller and changing the cutting knife mold. This flexibility enables customers to quickly adjust the production line according to market demand and improve competitiveness. Whether it is for small batch customization or large-scale production, customers can respond flexibly. Multi-specification production capacity not only meets the needs of different customers, but also enables customers to maintain flexibility in a changing market environment and reduce inventory risks.

Inkjet coding

KINGREAL uses advanced inkjet technology to allow customers to engrave their logo on the partition frame wall. This high-precision processing method not only enhances the personalization of the product, but also increases the exposure of the brand, making customers more prominent in the fierce market competition. By printing the brand logo on the product, customers can effectively improve their market awareness and enhance their brand image. In addition, the implementation of this inkjet technology does not affect the production speed. Customers can maintain the uniqueness of the product while producing efficiently.

Automated packaging system

In order to improve production efficiency, KINGREAL has equipped the partition frame wall making machine with an automatic packaging machine. The produced partition frame walls will be automatically transported to the packaging unit for packaging and stacking, reducing manual operations and improving work efficiency. This automated design not only saves labor costs, but also ensures the safety of the product during transportation. The introduction of the packaging machine makes the entire production process smoother and reduces errors and losses caused by human factors. Through automated packaging, customers can achieve higher production efficiency and lower error rates, further improving overall production benefits.