KINGREAL Cases -- Ceiling Channel Machine

2025-03-06 12:28In modern construction and manufacturing industries, ceiling channel machines, as an important equipment, play an indispensable role. KINGREAL has rich experience and technology, and is able to produce profiles of various types and sizes, such as C-shaped, hat-shaped, L-shaped, CD, UD, F-shaped ceiling channel etc. This article will explore in depth KINGREAL's false ceiling channel machines and their application cases in different countries, showing their wide demand and unique advantages in the building materials industry.

1. Overview of False Ceiling Channel Machines

False ceiling channel machines are a type of equipment specially used to produce ceiling channel profiles, mainly suitable for the building materials industry. These profiles are widely used to support ceilings, walls and other structural systems to form a complete ceiling system. KINGREAL's wall angle profile machines usually use GI steel and PPGI with a thickness range of 0.4-1mm as metal raw materials. These materials have good corrosion resistance and strength, and can meet the high standards of materials in the construction industry.

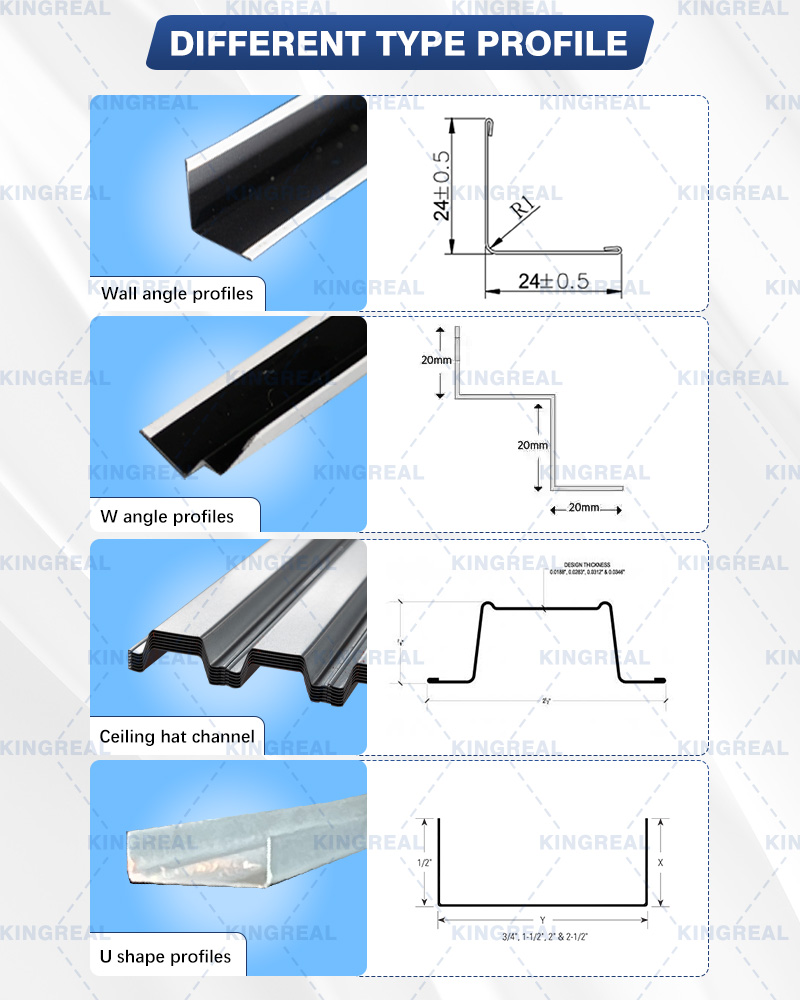

1.1 Types of ceiling channels

KINGREAL's ceiling channel machine can produce many different types of ceiling channels, including:

- C-shaped channel: widely used in construction and decoration, providing good structural support.

- Hat-shaped channel: often used to support ceiling systems, helping to fix and decorate.

- Angle angle channel: used to connect and support structures such as walls and ceilings, providing additional strength and stability.

- CD/UD profile: used for vertical and horizontal support of suspended ceiling systems to ensure the stability of the entire system.

- F-shaped channel: suitable for specific building needs, such as door frames and window frames.

1.2 Market demand of wall angle profile machine

The market demand for false ceiling channels is particularly significant in the Middle East, especially in Saudi Arabia, the United Arab Emirates, Qatar, as well as Russia and Ukraine. The construction industry in these countries is developing rapidly, and the demand for ceiling channels is increasing, mainly reflected in the following aspects:

- The booming construction industry: With the acceleration of urbanization, the demand for building materials in various countries has risen sharply.

- Advantages of ceiling channels: ceiling channel materials have the advantages of lightness, high strength and corrosion resistance, and have become an indispensable material in modern buildings.

- Environmental protection and energy saving: The use of ceiling channels helps to reduce the weight of buildings and reduce the burden on infrastructure, thereby achieving the goal of energy saving and environmental protection.

2. KINGREAL Cases -- Fasle Ceiling Channel Machine

Wall angle profile machine in Saudi Arabia

In Saudi Arabia, the demand for wall angle profile machines continues to rise. L-shaped profile machines are specially used to produce wall angle profiles. The finished products are often used with hat-shaped profiles and C-shaped profiles to form a complete building frame.

*Demand analysis of wall angle profile machine

The main reasons why Saudi Arabia has a demand for wall angle profile machines are as follows:

- Increase in construction projects: Saudi Arabia's infrastructure construction and real estate development are increasing, and the demand for ceiling channels has risen accordingly.

- Versatility of wall angle profiles: Wall angle profiles can be used for connection, support and decoration in buildings, and their design flexibility meets a variety of construction needs.

*Advantages of wall angle profile machine

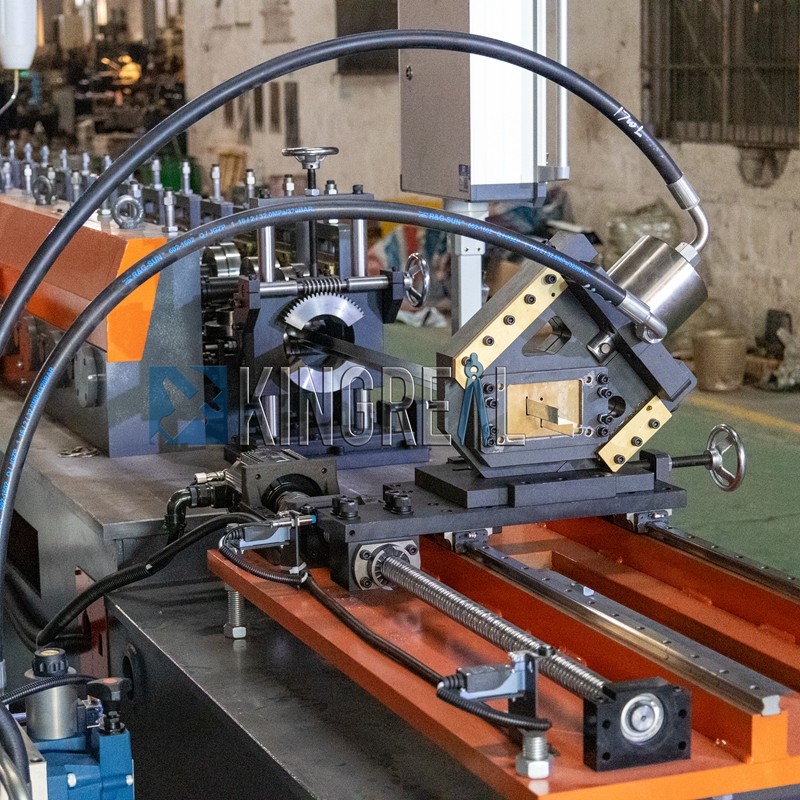

Swing shear system

The cutting station design with a swing shear system is extremely important in metal processing equipment. It not only significantly improves the precision and efficiency of shearing, but also effectively reduces material waste. The swing shear system accurately cuts metal materials into the required size through the swing of the mechanical arm. Compared with the traditional fixed shearing method, the swing shear system can speed up the shearing speed while maintaining high precision, making the entire production process smoother

High-speed

The application of high-speed forming technology has greatly improved the production capacity of the wall angle profile machine. The forming speed of this wall angle profile machine can be as high as 120 m/min, which greatly meets the needs of large-scale production. In the construction industry and manufacturing industry, time is money. Fast production capacity enables enterprises to complete a large number of orders in a short time and enhance market competitiveness. High-speed forming not only improves production efficiency, but also ensures the consistency and stability of products during the production process, and reduces production stagnation caused by slow speed

Equipped with a protective shield

In order to ensure the safety of workers when using metal processing equipment, the provision of a protective shield has become an important part of the design of modern wall angle profile machines. The installation of protective shields can not only effectively prevent accidental injuries, but also protect the factory environment and reduce the impact of dust and metal chips on air quality. This protective measure uses a closed design to ensure that workers will not come into contact with high-speed mechanical parts during the operation of the wall angle profile machine, thereby reducing safety hazards. In addition, the use of protective shields also meets the strict requirements of modern industry for safe production and improves the safety management level of enterprises.

Multi-specification false ceiling channel machine in Greece

The demand for ceiling channel machines in the Greek market should not be underestimated. In order to meet the production needs of different types of finished products, the multi-specification false ceiling channel machines provided by KINGREAL have become an ideal choice.

*Demand analysis of wall angle profile machine

Greece needs a machine to produce different types of finished products, mainly because:

- Market diversification: The construction market has diverse demands for ceiling channel profiles of different specifications and types.

- Improve production efficiency: Producing multiple profiles with one device can reduce production costs and space occupancy.

*Advantages of false ceiling channel machine

Different types of ceiling channel can be produced

The key to this function is its flexibility, which enables the production of multiple types of profiles such as C-shaped, cap-shaped and L-shaped profile on one production line. This means that users can quickly adjust the production line according to changes in market demand without investing in multiple equipment or making complex equipment changes. The entire replacement process takes only about 25 minutes, which significantly improves production efficiency and reduces the time and resource waste caused by equipment downtime compared to the replacement time of traditional equipment.

Double-head decoiler

The design of the double-head decoiler greatly improves production efficiency, especially in large-scale production environments. Its simultaneous operation on the left and right sides can minimize equipment downtime. While unwinding on the left side, the material can be loaded on the right side. This synchronous operation ensures the continuity of the production process and avoids losses caused by waiting.

False ceiling channel machine with auto packaging unit in Mexico

In Mexico, with the rapid development of the construction industry, the demand for automated packaging machines is also rising. Due to the high local labor costs, automated equipment has become an effective way for companies to reduce costs.

*Demand Analysis of false ceiling channel machine

The demand for automatic packaging machines in Mexico is mainly affected by the following factors:

- High labor costs: Local labor costs are rising year by year, and companies hope to reduce labor costs through automated equipment.

- Production efficiency requirements: Customers' requirements for production efficiency and product quality are constantly increasing, and automated equipment can effectively meet these needs.

*Advantages of false ceiling channel machine

Flying shear system

Flying shear technology is an important innovation in modern metal processing equipment, which greatly improves the efficiency of the shearing process. The notable feature of flying shear technology is that it can be sheared without stopping, which means that the production process can be continuous without stopping due to shearing. This continuous production capacity not only improves production efficiency, but also reduces the time and resource waste caused by equipment downtime.

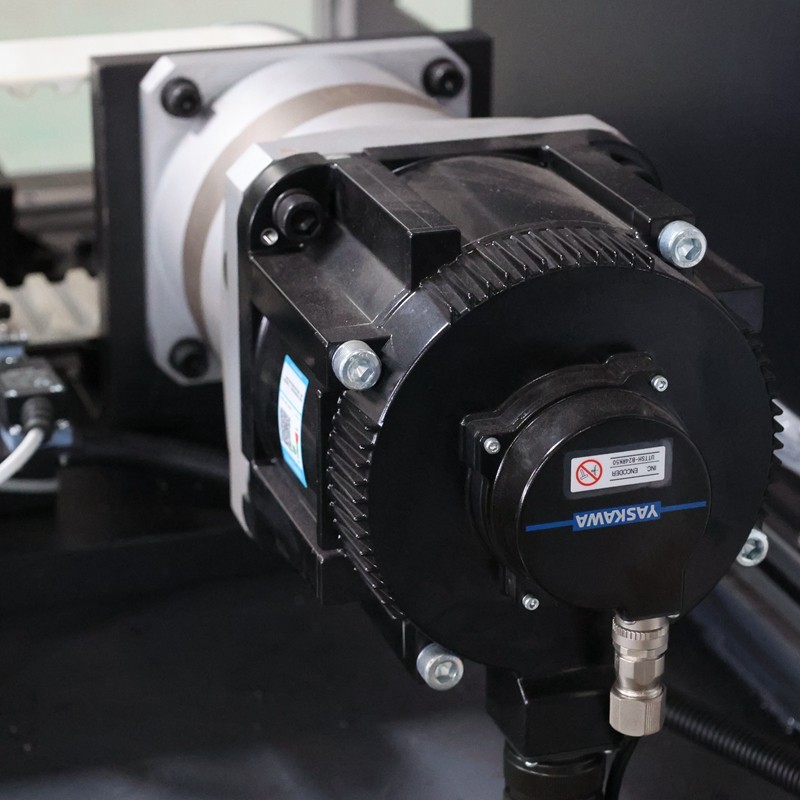

4.4KW servo motor

The application of 4.4KW servo motor in false ceiling channel machine provides strong guarantee for the stability and reliability of the equipment. This efficient servo motor can maintain consistent performance under various load conditions, ensuring that the wall angle profile machine can still run smoothly when working at high intensity. The precise control characteristics of the servo motor make the equipment respond quickly during operation and adapt to various production needs, thereby improving the overall performance.

Intelligent packaging machine

The introduction of intelligent packaging unit has brought revolutionary changes to the metal processing industry. After the profile is processed by the false ceiling channel machine, it is automatically sent to the packaging unit for packaging, and this process requires almost no human intervention. This fully automated packaging process not only reduces labor costs, but also greatly reduces the error rate and safety hazards caused by manual operation.

KINGREAL Packing & Delivery Service