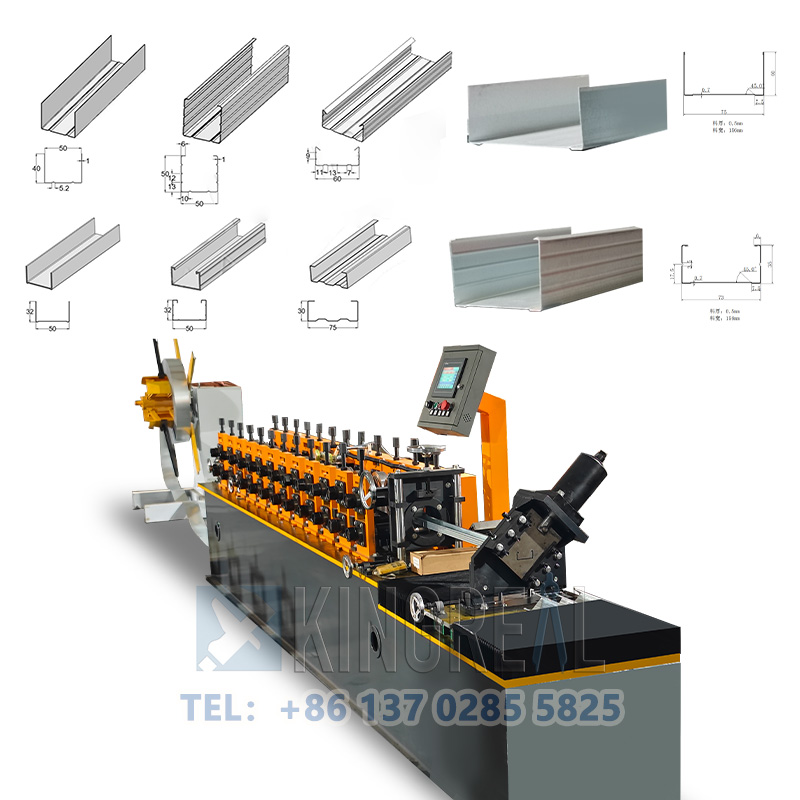

KINGREAL Gypsum Channel Machine to Greece

2025-02-13 12:18KINGREAL Gypsum Channel Machine to Greece

KINGREAL successfully customized a gypsum channel machine with inkjet coding for a Greek customer. The equipment was strictly tested and tested by KINGREAL staff to ensure that it can run smoothly and produce gypsum channel with different sizes and high precision. After comprehensive inspection and confirmation, the gypsum channel making machine was successfully packaged and sent to Greece.

Greek customers' evaluation of KINGREAL

With inkjet function

Greek customers highly recognized the function of KINGREAL's gypsum channel roll forming machine, especially the customized service with inkjet. During the forming process of the gypsum channel, the machine can engrave the customer's logo on the gypsum channel through the roll forming machine. This function not only enhances the brand value of the product, but also saves customers time and cost for secondary processing after discharging, making the overall production process more efficient.

High precision of finished products

Customers gave positive comments on the precision of the finished products. KINGREAL's gypsum channel production line can produce highly consistent gypsum channels under the same parameter conditions, which is crucial for the production of building materials that require high precision and consistency. Greek customers said that the high precision and high consistency of KINGREAL's gypsum channel roll forming machine greatly improved their production efficiency and product quality.

Meticulous service

From the early stage to the middle and late stages of the project, KINGREAL's staff always followed up and responded quickly, making customers feel valued. Greek customers specifically mentioned that KINGREAL's timely communication and professionalism during the machine manufacturing period made them confident in the entire project. KINGREAL not only pays attention to the quality of the product, but also is committed to providing meticulous service to ensure that customers can get help and support at any time throughout the project.

Offline installation and training

KINGREAL's engineers also provide customers with offline installation and operation training of the gypsum channel machine to ensure that the customer's operators can master the use of the equipment. This service makes Greek customers feel at ease. They believe that this safeguard makes subsequent production smoother and can better deal with possible failures and problems.

Important parts of gypsum channel machine

Decoiler

The decoiler is an important part of the KINGREAL gypsum channel making machine, which is responsible for automatically uncoiling the metal coil. The gypsum channel production line runs automatically according to the parameters adjusted by the system, with the advantages of fast speed and no need for manpower. This design not only improves production efficiency, but also reduces the workload of workers, making the production process smoother.

Roll forming machine

KINGREAL's gypsum channel production line can produce gypsum channels of different sizes by adjusting the rollers. Workers only need to enter the parameters on the intelligent control panel, and the rollers on the roll forming machine will automatically adjust the width according to the instructions. This intelligent design greatly improves the flexibility of production.

Flying punch and flying shear

KINGREAL has equipped the gypsum channel making machine with a hydraulic flying punch and shear station. During the shearing process, the gypsum channel making machine will not stop. This design significantly improves the production capacity of the machine. It is worth mentioning that the equipment is equipped with two shearing stations, which can simultaneously shear the punched gypsum channel. This efficient design ensures the reliability and stability of the equipment in a high-load production environment.