Installation Service: Open Cell Ceiling Machine

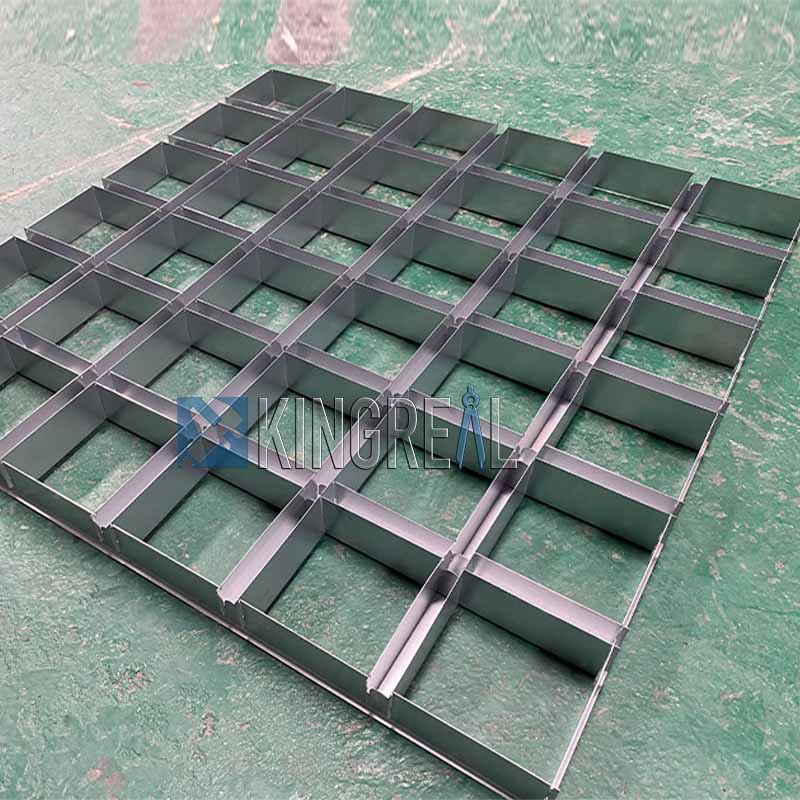

2024-12-19 11:35Recently, the KINGREAL open cell ceiling machine successfully passed the quality inspection after rigorous trial testing. The staff put the metal raw materials into the equipment for comprehensive testing to ensure that the machine runs smoothly, has stable performance, and can produce open cell ceiling sizes that fully meet customer needs. The test results show that the precision error of the finished product is controlled within 0.1mm, which fully demonstrates the high precision and reliability of KINGREAL equipment.

Customized solutions to meet customer needs

During the in-depth communication with Russian customers, KINGREAL engineers learned in detail about the customer's production requirements for open cell ceilings of different sizes. According to customer needs, engineers customized a high-performance open cell ceiling machine for it, equipped with multiple sets of special molds and a 63-ton punching station. The punching station can complete the efficient punching operation of the product at one time, greatly improve production efficiency, and meet the diverse product specification requirements.

Delivery and Outlook

After a series of rigorous tests and customized adjustments, this exclusive open cell ceiling production line has been successfully shipped to the Russian customer factory.

KINGREAL has always been committed to providing customers with high-quality equipment and services, helping customers achieve higher production benefits through precise customization and all-round support.

KINGREAL Installation Service

Last week, KINGREAL sent engineers to the Russian customer's factory to install the open cell ceiling production line.

In order to ensure the efficient operation and excellent quality of the open cell ceiling production line, KINGREAL engineers strictly followed the standardized process during the installation process.

The following are the detailed installation steps:

1. Pre-installation preparation

Before the formal installation, first open the equipment package and carefully check whether all parts are intact. KINGREAL engineers check and test the core components of the production line one by one, including but not limited to the following equipment:

Decoiler: used to unroll metal coils;

Leveler: ensure that the metal material is flat and wrinkle-free;

Roll forming machine: used to shape metal;

Punching machine: accurately punch holes for open cell ceiling products.

Through careful inspection, ensure that all parts are not damaged during transportation, laying the foundation for subsequent installation.

2. Machine installation process

After completing the component inspection, KINGREAL engineers use professional equipment such as forklifts to put the main components in place one by one according to the planned position. Subsequently, the open cell ceiling production line equipment was officially installed to ensure that each machine was firmly connected and met the design requirements.

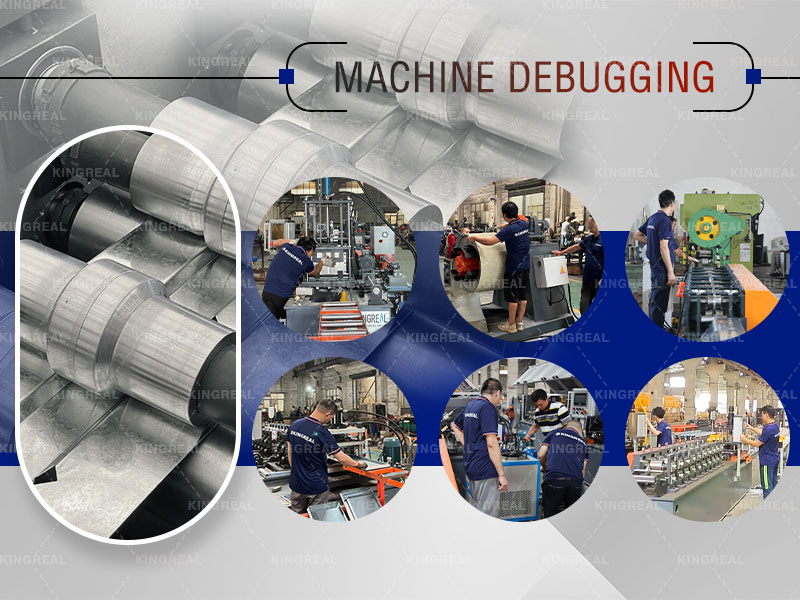

3. Debugging and precision testing

After the equipment was installed, the engineer debugged the entire production line:

Adjust the open cell ceiling punching die to ensure the punching accuracy;

By running the open cell ceiling machine, the grilyato product was precisely measured to check whether the size met the design standards;

Test different production parameters to ensure that the equipment can operate stably and produce high-quality grille products.

4. Worker operation training

After the open cell ceiling machine was debugged and confirmed to be operating normally, the engineer began to conduct systematic training for Russian workers, including:

Operation instructions: explain in detail how to adjust the width, height and length of the open cell ceiling through the CNC system;

Size customization: demonstrate how to quickly switch the production mode of open cell ceilings of different sizes;

Maintenance skills: teach daily maintenance of equipment and common problem handling methods.

Engineers also pay special attention to the actual operation ability of workers, and ensure that each worker can master the skills of using equipment through practical teaching. After the training, the engineer supervises the workers to operate the open cell ceiling production line independently and patiently answers all the questions they encounter during the operation.

5. Results and guarantees after installation

Through a series of rigorous installation, commissioning and training work, KINGREAL engineers ensure that the open cell ceiling production line can operate efficiently and help the customer team quickly get started, creating higher production value for customers.

Russian customers are highly satisfied with the after-sales service provided by KINGREAL this time. They reported that after systematic training, the workers have been able to operate the equipment proficiently and the production efficiency has been significantly improved.