New design: 300mm height baffle ceiling machine

2024-12-17 14:31KINGREAL's New Design

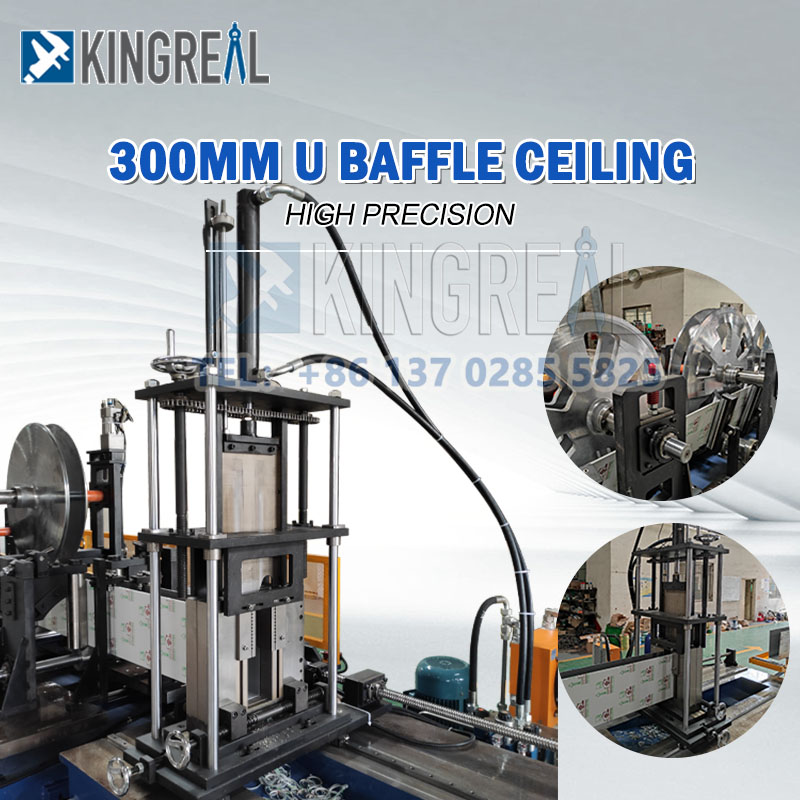

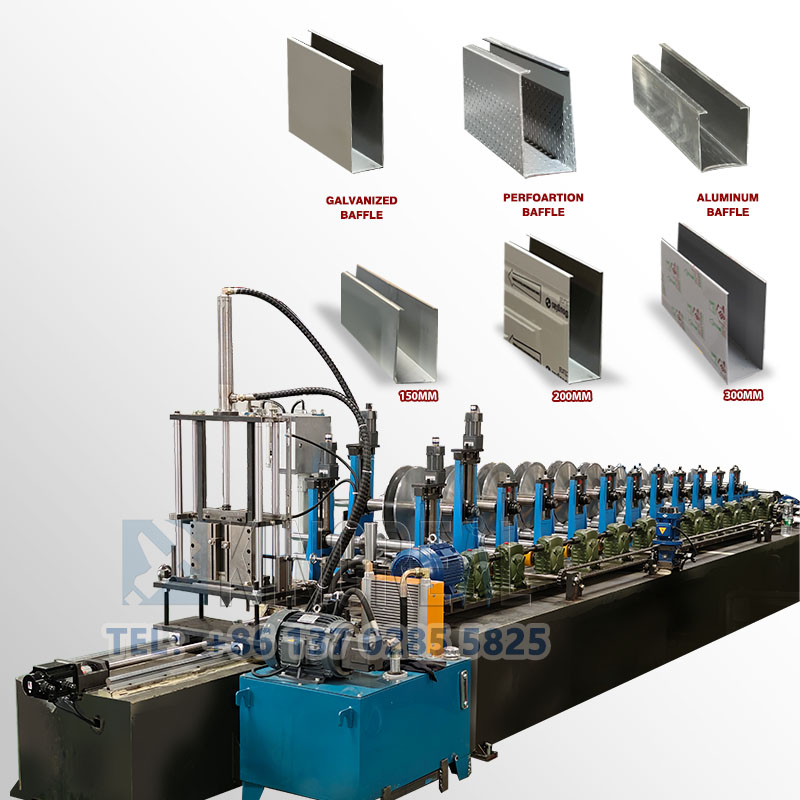

After research, KINGREAL engineers have launched a new design of a 300mm height baffle ceiling machine. Compared with the most common u baffle machines on the market, the rollers of KINGREAL 300mm height baffle ceiling machine use a hollow design, which can avoid the indentation of the finished product due to the weight of the rollers, ensuring that there is no indentation on the surface of the finished baffle ceiling. And the newly designed KINGREAL baffle ceiling machine can produce baffle ceilings up to 300mm.

After in-depth research and technological innovation, KINGREAL's engineering team has successfully launched a newly designed 300mm height baffle ceiling machine. Compared with the common u baffle machines on the market, KINGREAL's equipment has achieved breakthroughs and optimizations in many aspects, especially the hollow structure in the roller design of the roll forming machine.

The rollers of traditional baffle ceiling machines are often heavy, and they are easy to produce indentations on the surface of baffle ceilings during the forming process, affecting the appearance and quality of the finished product. KINGREAL engineers innovatively adopted a hollow roller design, which effectively reduced the weight of the roller and significantly reduced the pressure on the surface of the baffle ceiling during the forming process.

This design not only completely solves the indentation problem, but also ensures that the surface of the finished baffle ceiling is smooth and flat without any indentation defects, meeting the stringent requirements of the high-end market for product quality.

In addition, KINGREAL's newly designed baffle ceiling machine can stably produce u baffle ceilings with a height of 300mm. This height breaks through the production limit of most u baffle machines on the market, providing customers with a wider range of product specifications to meet the needs of different building decoration projects.

Whether it is a large commercial building or a high-end interior decoration, KINGREAL's 300mm height u baffle machine can provide high-quality and stable production solutions.

Why do we need 300mm height baffle ceiling machine?

The birth of KINGREAL's 300mm height baffle ceiling machine is due to the special requirements of Douglas, the customer. He has higher requirements for the size of the baffle ceiling, especially hoping to produce a baffle ceiling with a height of 300mm. To this end, Douglas provided his design drawings to KINGREAL and asked whether a baffle ceiling machine that meets this specification could be developed.

Faced with this challenge, KINGREAL's engineering team quickly carried out in-depth research, conducted multiple full and detailed communications with customers, and accurately understood all of Douglas' requirements for equipment performance, finished product quality, and production stability. After repeated technical demonstrations and design optimization, KINGREAL finally successfully developed a 300mm height baffle ceiling machine, which not only met customers' special needs for baffle size, but also exceeded customers' expectations in production efficiency and finished product quality.

Douglas was very satisfied with this and spoke highly of KINGREAL's professional technology and customized services.

In fact, with the development of the building decoration market, more and more customers have put forward higher and more personalized requirements for the size, shape and quality of baffle ceilings. Traditional baffle ceiling machines are often difficult to meet the production needs of large sizes, and KINGREAL's 300mm height baffle ceiling machine was born to solve this pain point. The launch of this equipment not only fills the technical gap in the market, but also provides customers with more choices, helping them stand out in the fierce market competition.

If you also have special production needs or personalized baffle design solutions, KINGREAL welcomes you to give us your drawings and ideas. Our team of engineers will fully combine your actual needs, provide professional customized solutions, and tailor a baffle ceiling machine specifically for you to ensure stable equipment performance and excellent finished product quality, helping you achieve your production goals and create greater value together!

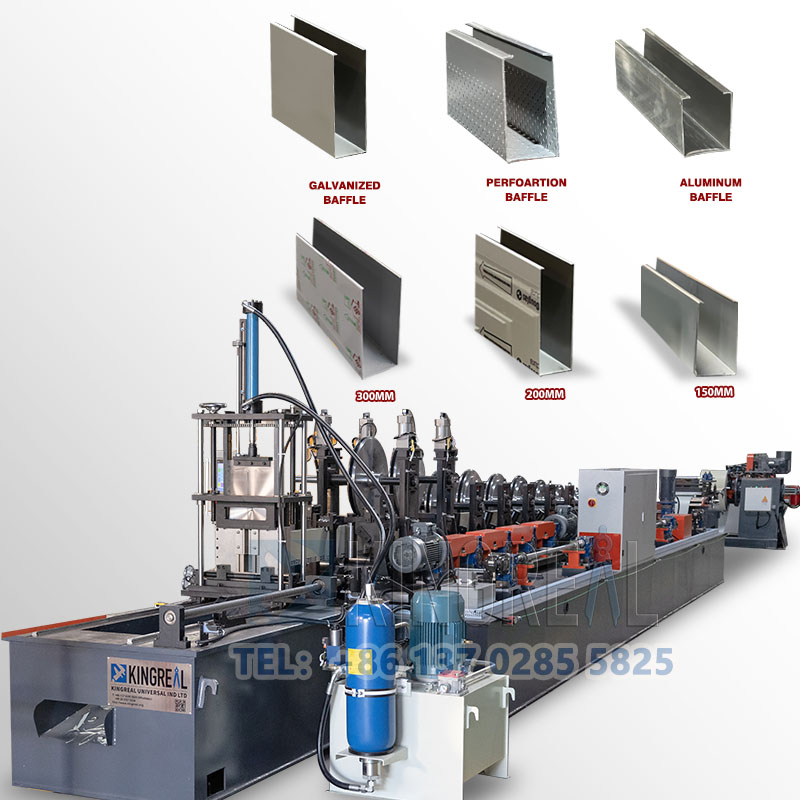

KINGREAL's baffle ceiling machine

KINGREAL u baffle machine has the following features:

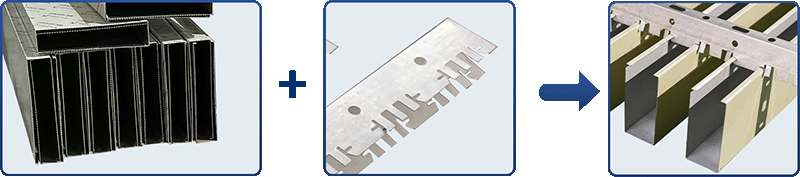

Provide a complete U-shaped baffle ceiling solution

KINGREAL baffle ceiling machine can be used in conjunction with baffle ceiling carrier machine to form a complete U-shaped baffle ceiling production line.

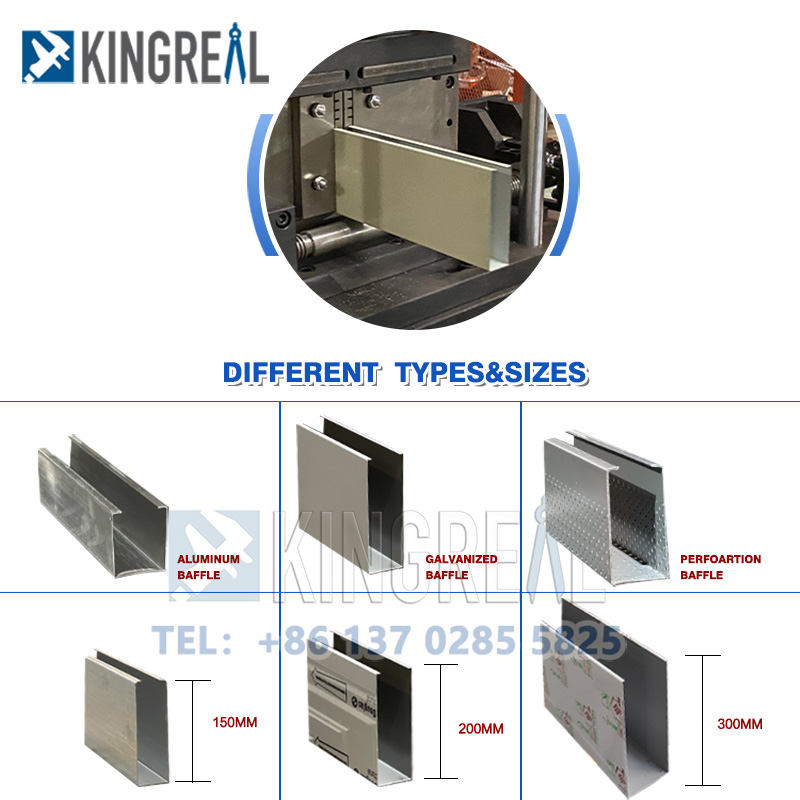

One machine produces finished products of various sizes

KINGREAL baffle ceiling machine can automatically adjust the width to produce u baffle ceilings of different sizes to meet customers' needs for diversified products. This feature greatly reduces the equipment investment cost and improves the flexibility and economy of production.

Production speed up to 30m/min

KINGREAL u baffle machine has super high production efficiency, the fastest speed can reach 30 m/min, significantly shortening the production cycle.

Follow shearing

The shearing system uses follow shearing. You only need to enter the required cutting parameters, and the system can detect the length of the baffle ceiling material through the sensor and control the tool to cut at the right time.

In addition to the 300mm height baffle ceiling machine, KINGREAL also provides a variety of special models to meet the production needs of different customers:

200mm baffle ceiling machine

Economical baffle ceiling machin