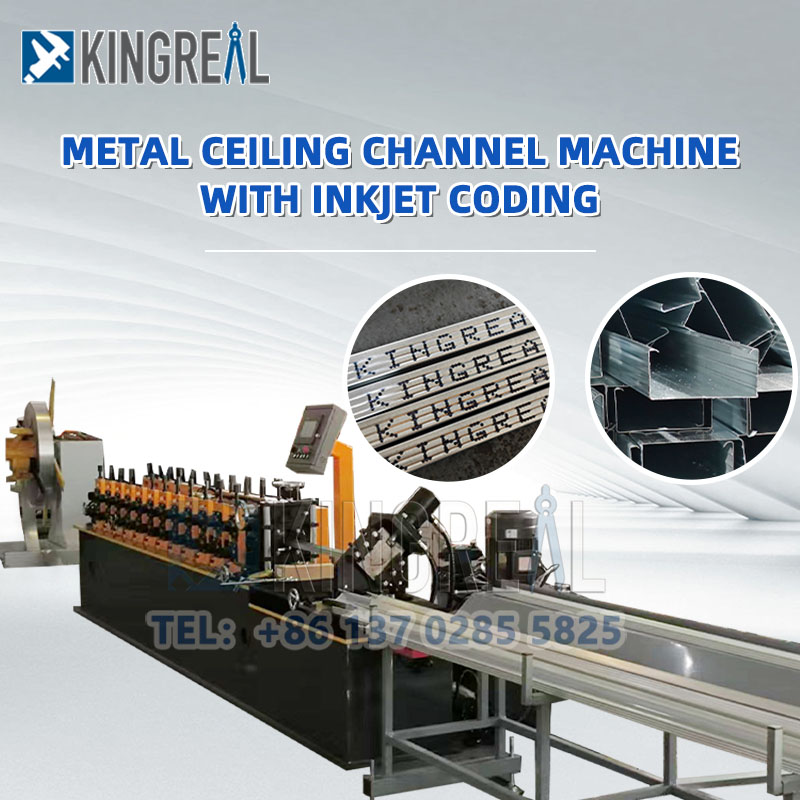

New Design -- Ceiling Channel Machine with Inkjet Coding

2024-12-16 16:46Ceiling Channel Machine with Inkjet Coding Shipped to Greece

Last week, after the strict testing of the KINGREAL technical team, the KINGREALstud and track machine with inkjet coding was confirmed to be able to run stably, and the maximum production speed can reach 100m/min, and it can produce wide and narrow studs and tracks of different sizes with high precision, etc., and then the ceiling channel machine was sent to the Greek customer's factory.

KINGREAL's new design - ceiling channel machine with inkjet coding

The stud and track machine with inkjet coding is KINGREAL's latest design. It combines advanced inkjet technology and efficient production capacity, and can print customer brand logos or customized texts during the production process.

With the intensification of market competition, more and more companies are beginning to pay attention to brand communication and market differentiation. Traditional production equipment often cannot reflect brand elements or customized information on products, while KINGREAL's stud and track machine with inkjet function can directly print brand logos, corporate slogans or other customized texts during the production process, which not only increases the added value of the product, but also provides customers with a convenient way to promote their brands, helping them stand out in the market.

Why do you need a ceiling channel machine with inkjet?

1. Improve brand exposure

By directly printing the customer's brand logo or customized text on the studs and tracks, KINGREAL's ceiling channel machine with inkjet coding makes each drywall studs and tracks a carrier of brand promotion. This customized design can effectively improve the exposure of the customer's brand, especially in large-scale construction projects. The stud and track, as an invisible structural material, can continuously convey brand information and increase brand influence during long-term use.

2. Improve production efficiency

The traditional studs and tracks process requires additional steps for identification or printing, while KINGREAL's ceiling channel machine with inkjet function integrates this process into the production line, reducing manual operation and time costs. The inkjet function can be completed in real time during the production process without the need for a separate identification link, which greatly improves production efficiency and saves manpower and time resources.

3. Customized flexibility

Customers can freely customize the printing content according to their needs, not only limited to brand logos, but also specific text, numbers or any other information. This flexibility makes the production process more personalized and can meet the needs of different customers, especially in large-scale production or project customization, which can achieve highly personalized production.

4. Reduce post-production labor costs

The KINGREAL ceiling channel machine with inkjet function can automatically complete the printing work, reducing the need for manual spraying and marking. Traditional printing methods often require manual operation, which is prone to unevenness or errors, while the automatic inkjet system can ensure the consistency and accuracy of the printing effect, reducing rework or waste caused by human factors.

Advantages of KINGREAL ceiling channel machine

In addition to the inkjet function, the KINGREAL stud and track machine also has the following advantages:

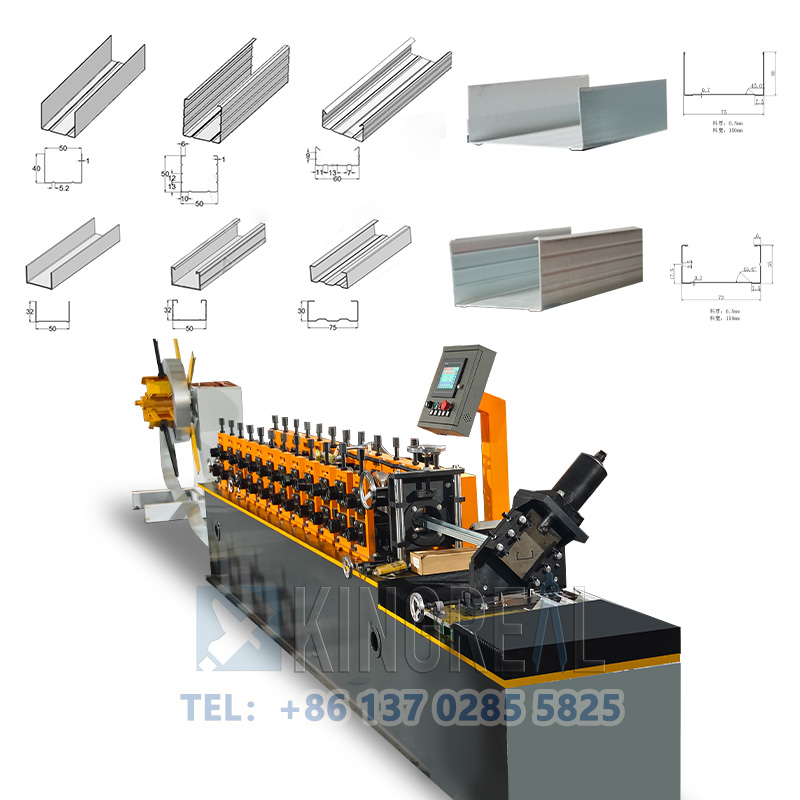

1. Can produce studs and tracks of different widths

The KINGREAL stud and track machine adopts an advanced servo motor system, which can realize automatic adjustment to ensure that the width of the stud and track can be adjusted quickly and accurately during the production process. The entire roller width adjustment process only takes 10 minutes, which greatly saves customers' production time. Whether the customer needs to produce narrow or wide studs and tracks, the equipment can respond flexibly to meet the needs of different projects. This design not only improves production efficiency, but also improves product diversity, helping customers better adapt to the market demand for studs and tracks of different specifications.

2. High-speed production

The maximum production speed of KINGREAL stud and track machine can reach 100m/min, which greatly exceeds the production capacity of traditional equipment. High-speed production not only increases the output of the production line, but also helps customers reduce the production cycle, thereby reducing unit costs. Whether it is large-scale production or urgent orders, KINGREAL's high-speed equipment can ensure that customers can complete more products in a shorter time, improve overall production efficiency, and ensure customers' competitiveness in the market.

3. With automatic package unit

In order to further optimize the production process, KINGREAL provides customers with automatic package unit to help customers reduce manual operations and improve the automation level of the production line. The automatic package unit can automatically perform baling after the production is completed, ensuring that the product packaging is standardized and neat, and reducing errors and inconsistencies in the manual packaging process. Through this function, customers can not only save labor costs, but also improve packaging efficiency, ensure that the product is not damaged during transportation and storage, and further improve the overall efficiency and accuracy of the production line.