New Design: Strut Channel Machine with Auto Package Unit

2024-12-13 16:38Unistrut roll forming machine is one of KINGREAL's hot-selling products, with more than 50 units sold. KINGREAL has established friendly cooperative relations with customers from Russia, India, Poland, the United States, Canada and other countries, especially Canada, Mexico, the United Kingdom and other countries, and has precisely customized strut channel machine. With rich manufacturing experience and a deep understanding of local market needs, KINGREAL can accurately meet customers' needs for solar panel roll forming machine parameters.

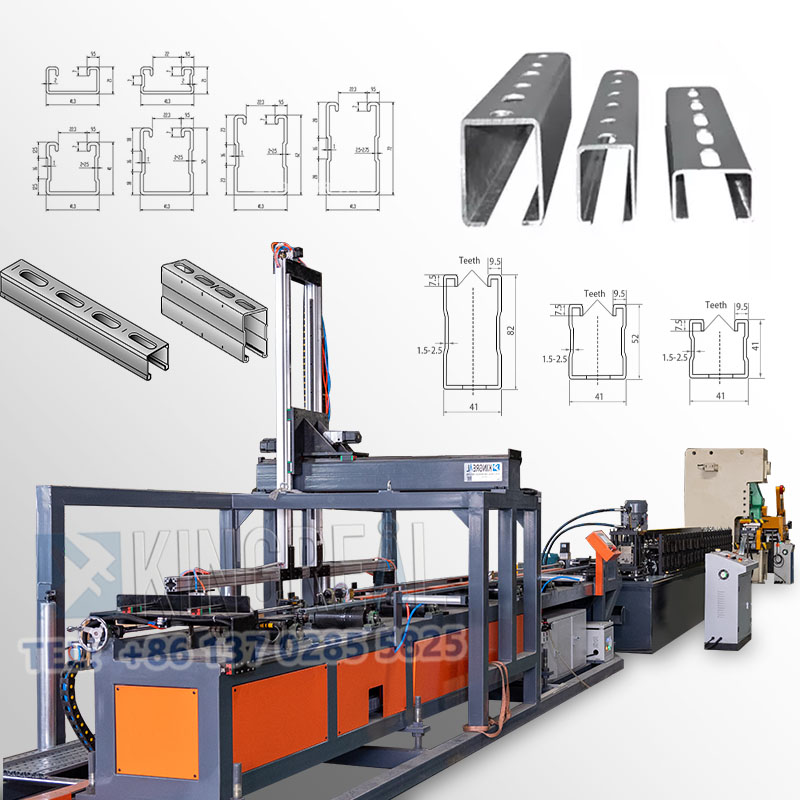

Introduction of solar panel roll forming machine

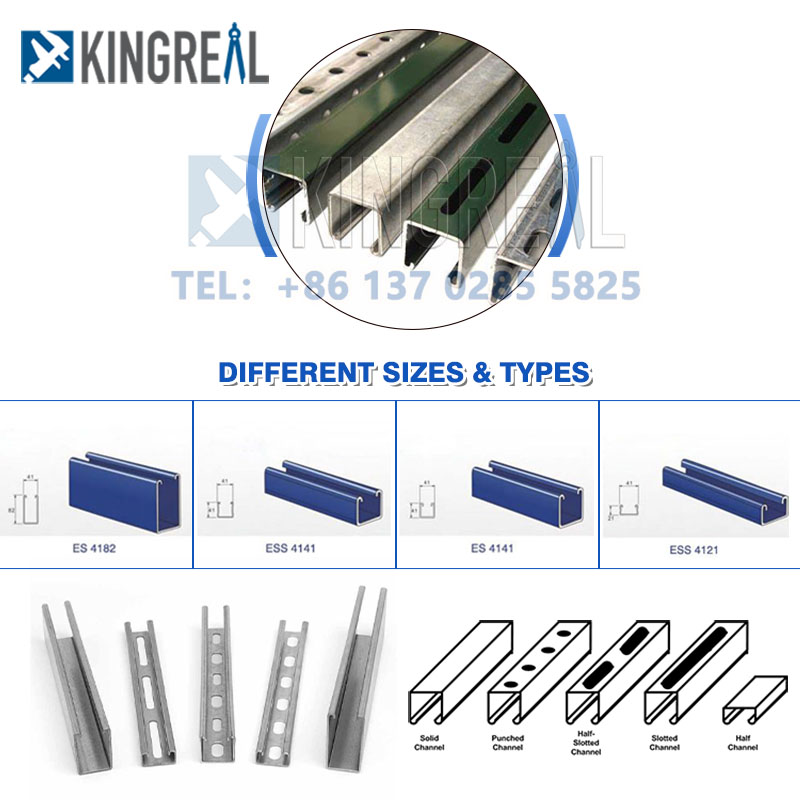

The slotted strut channel roll forming machine can produce different types of strut channels, including slotted channel, long slot strut channel, short slot strut channel, solid strut channel, etc. The common finished product sizes are 41 × 21mm, 41 × 41mm, 41 × 62mm, 41 × 82 mm.

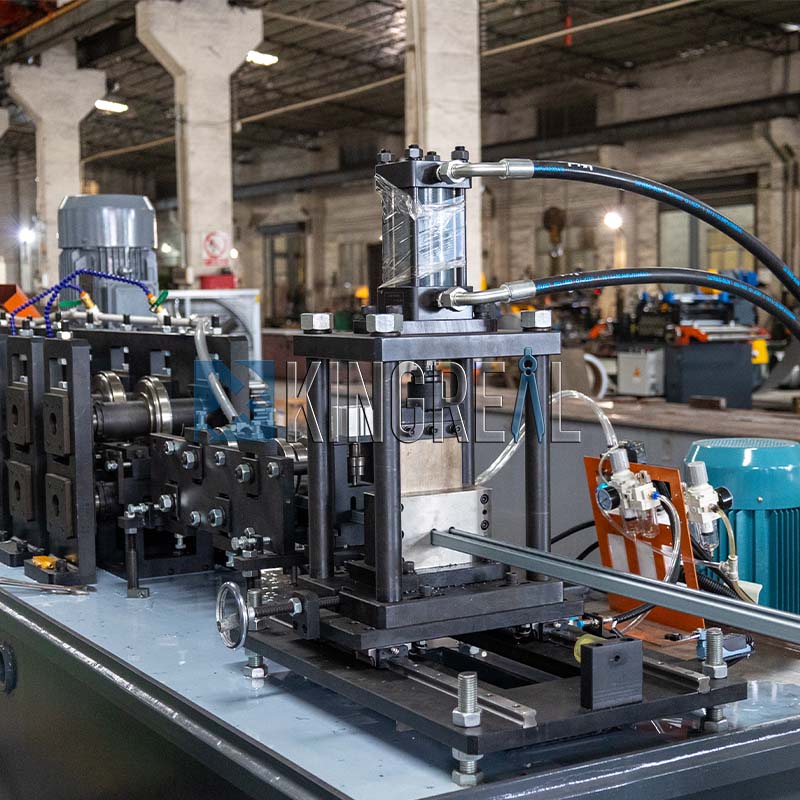

The unistrut roll forming machine is mainly composed of precision components such as decoiler, leveling machine, punching equipment, roll forming machine, hydraulic shearing station, material receiving table, electrical system, etc.

The strut channel machine has two main application areas. One is to fix and support photovoltaic modules and adjust their angles and directions to maximize the reception of sunlight. The other is to use them as seismic brackets in the seismic structures of building electromechanical systems. They are mainly used for the support and fixation of equipment such as pipelines, cable trays, ventilation ducts, etc., to ensure that the equipment can remain stable under dynamic loads such as earthquakes and avoid damage or falling off.

Advantages of solar panel roll forming machine

Auto package unit.

In order to maximize the production speed of customers, KINGREAL has designed an automatic package unit for unistrut roll forming machine. When the strut channel comes out of the discharging platform, it is directly sent to the baler for automatic baling and stacking. The process of manual handling, baling and stacking in the middle is eliminated, saving time and labor costs for the factory.

One production line can produce finished products of two different sizes.

KINGREAL slotted strut channel roll forming machine can meet customers' production needs for strut channels of different specifications of 41x41mm and 41x21mm by manual adjustment or changing rollers.

2 in 1 decoiler and leveling machine.

It integrates unwinding and leveling, reduces installation space, and reduces the transition link in the straightening process of metal materials.

Follow-up shearing station.

KINGREAL strut channel machine is equipped with a follow-up shearing station, which means that there is no need to stop the machine during cutting. It greatly reduces downtime, improves production efficiency, and reduces the waste of metal materials.

Adjustable speed.

The maximum forming speed of KINGREAL unistrut roll forming machine is 10-15 m/min. Customers can adjust the machine speed according to actual production needs.

Customizable.

KINGREAL slotted strut channel roll forming machine can produce 41 × 21mm, 41 × 41mm, 41 × 62mm, 41 × 82 mm. If customers have special size and thickness requirements for strut channels, please submit drawings to KINGREAL, and engineers will make customized solar panel roll forming machines for customers.

Why choose KINGREAL?

1. Rich experience

KINGREAL has more than 20 years of experience in roll forming machine manufacturing, and has formed a unique production process and management method to ensure the high quality and efficiency of the machine. The company is equipped with an experienced team of engineers to provide professional support to customers.

2. Meticulous service

KINGREAL always focuses on customer needs and provides comprehensive and thoughtful services:

● 24-hour customer service support: Quickly respond to customer questions, provide professional answers, and ensure that customer questions are resolved in a timely manner.

● Factory on-site visit: Arrange to pick up customers to visit the KINGREAL factory, accompanied by staff throughout the whole process, introduce the machine operation in detail, and show whether the finished product meets the customer's production needs.

● Perfect after-sales service: KINGREAL can dispatch engineers to the customer's factory to complete the installation of the machine and provide operation training for workers. If the machine fails, the company can arrange professional technicians to repair it on site to ensure smooth and worry-free production for customers.