Coil Perforation Line Purchasing Guide

2025-02-07 12:16In modern manufacturing, coil perforation line is an important metal processing equipment, which is widely used in the construction, automobile, home appliances, electronics and other industries. Metal perforated machine processes metal coils into products with various hole shapes by punching, shearing and other processes. Choosing a suitable coil perforation line is crucial to improving production efficiency and ensuring product quality.

Introduction to the metal perforated machine

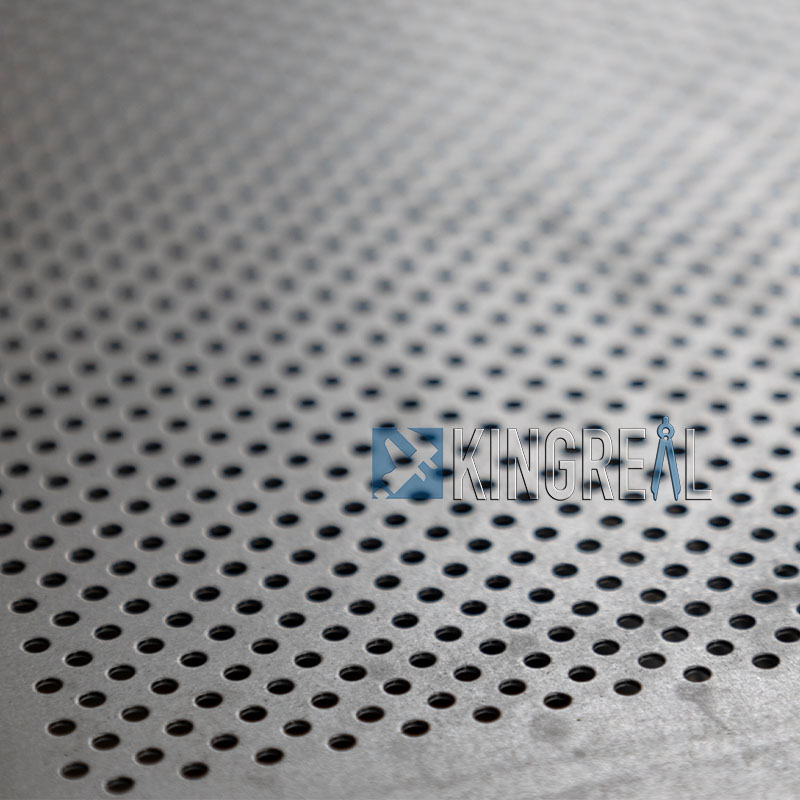

Metal perforated machine is a production equipment used to punch metal coils, usually consisting of an decoiler, a punching machine, a cut to length machine, a recoiler, etc. After continuous processing by the coil perforation line, the metal coils eventually become various metal materials with holes, which are widely used in the fields of building materials, home appliances, and automotive parts.

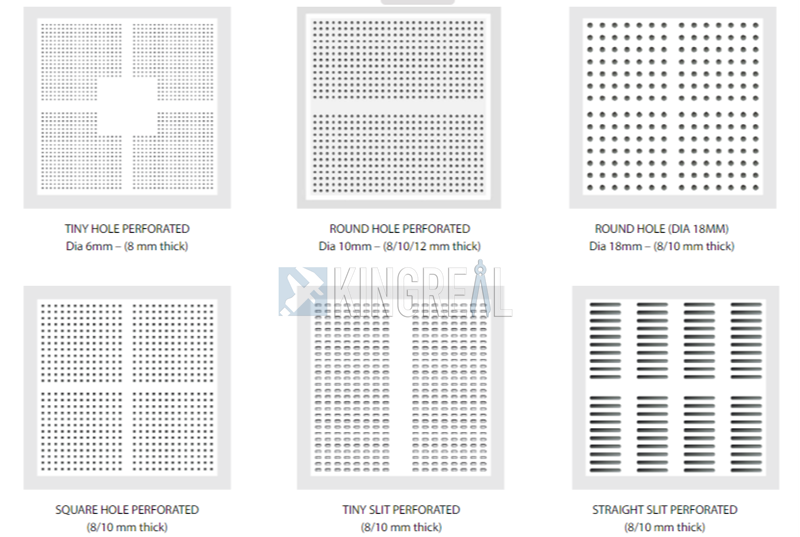

Common shapes and types of punching holes include:

✦ Round holes

✦ Square holes

✦ Long holes

✦ Diamond holes

✦ Mesh hole

Coil perforation line can be customized with hole shapes of different types and sizes according to customer needs. Therefore, understanding common punching shapes and application areas is very important for purchasing decisions.

Market development of metal perforated machines

With the development of the manufacturing industry, especially the increase in demand for high-quality metal materials, the coil perforation line market has expanded rapidly. In the past, the application of metal perforated machine was relatively single, mainly focusing on simple hole processing.

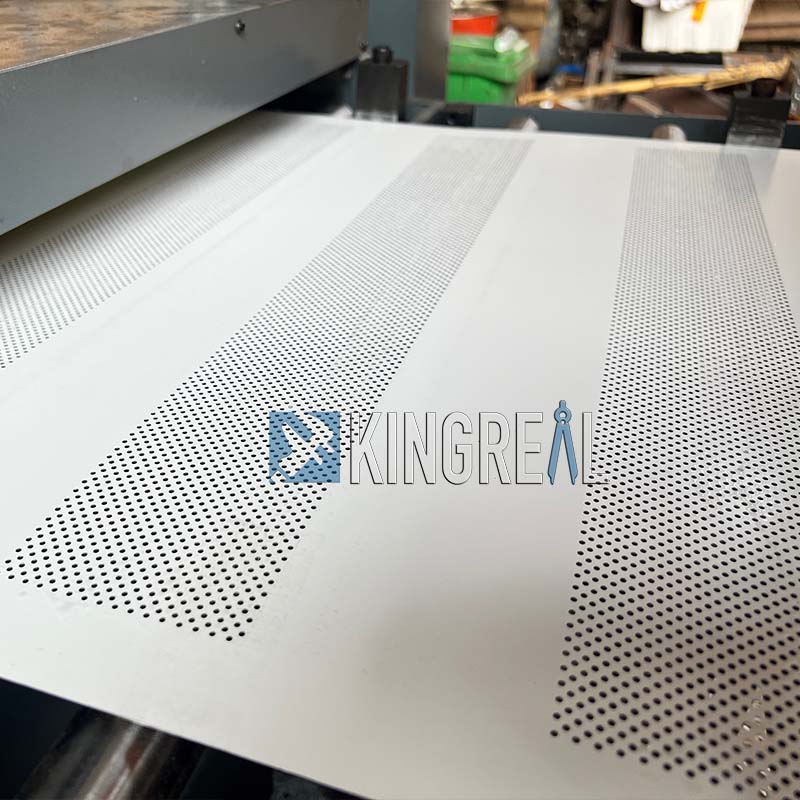

But with the advancement of technology, modern punching wires can not only process holes of various shapes, but also provide high-speed and high-precision production capabilities. Especially in the automotive, construction, home appliance and other industries, the requirements for hole size and quality are getting higher and higher, the technology of metal perforated machines is constantly upgraded, and the trend of automation and intelligence has gradually become the mainstream of the market.

How to choose a metal perforated machine?

To choose a suitable coil perforation line, the following key factors should be considered first:

(1) According to actual production needs

Metal perforated machines can usually be divided into three main types according to production needs:

- Metal sheet coil perforated cutting production line:

This coil perforation line has an automatic shearing function while punching. It is suitable for production scenarios where metal strips need to be punched and cut to length. For example, punching and shearing into standard-sized metal plates.

- Coil perforated rewinding production line:

This equipment is mainly used to wind metal coils with holes into coils, which is suitable for production scenarios where metal coils need to be processed after punching, such as filters, ventilation equipment, etc.

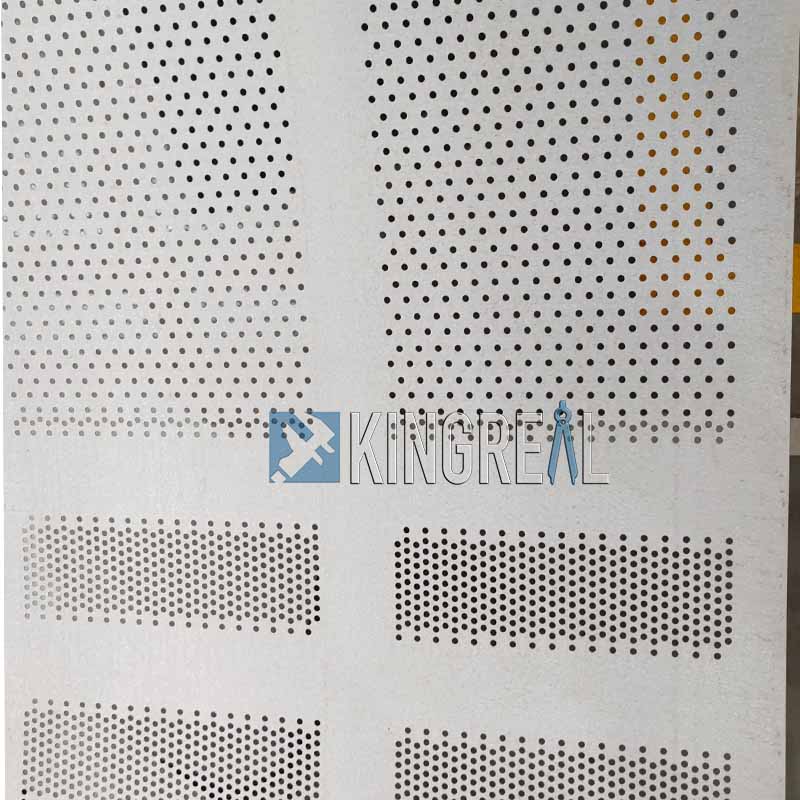

- Metal ceiling tile perforation line:

A metal perforated machine specially used for manufacturing metal ceilings. This equipment not only has the punching function, but also can perform customized punching and cutting, which is suitable for the construction industry's demand for ceiling materials.

(2) Raw material parameters

When choosing a coil perforation line, the configuration of the equipment must be determined according to the type and thickness of the metal material being processed. Different metal materials (such as stainless steel, aluminum alloy, iron plate, etc.) have different physical properties. During the punching process, the impact force, speed and mold of the machine need to be adjusted according to the characteristics of the material.

In addition, the thickness of the raw material is also an important criterion for selecting a coil perforation line. For thinner metal plates, a metal perforated machine with a smaller tonnage is usually selected; for thicker metal plates, a metal perforated machine with greater impact force and stability needs to be selected.

(3) Required punching version

When selecting a coil perforation line, it is necessary to select a suitable coil perforation line based on the parameters such as the hole type, hole diameter and hole spacing required in the production process. Common versions include round holes, square holes, long holes, mesh holes, etc. Different hole types require different punching dies. The adaptability and flexibility of the equipment are one of the key considerations when selecting a metal perforated machine.

(4) Specific applications after production

Different types of metal perforated machine solutions are suitable for different application areas. For example, when producing metal ceiling sheets for construction, larger apertures and specific hole shapes may be required, while when producing metal parts for the home appliance industry, smaller apertures and higher precision may be required. Clarifying the specific application of the metal perforated machine after production will help choose the most appropriate equipment configuration and technical parameters.

(5) According to the scale of production

The choice of metal perforated machine should also be determined according to the scale of production. For manufacturers with different production scales, different tonnage coil perforation lines need to be selected. Common coil perforation lines are 160 tons and 200 tons. The selection of coil perforation line tonnage needs to be based on factors such as punching area and punching thickness. It is worth mentioning that KINGREAL's 160-ton perforated metal production line can reach a maximum speed of 200-220spm.

Why choose KINGREAL?

When choosing a metal perforated machine supplier, KINGREAL, as an equipment manufacturer with rich experience and technical accumulation, has become the first choice of many customers with its excellent quality and perfect after-sales service.

(1) Project experience

KINGREAL has many years of experience in providing coil perforation lines to customers around the world, and has successfully provided customized punching solutions for customers in multiple industries. Whether it is metal processing, building materials, home appliance manufacturing, or automotive parts production, KINGREAL has accumulated rich project experience and can provide professional advice and solutions based on the specific needs of customers.

(2) Strict machine production process

KINGREAL strictly follows international standards during the equipment production process to ensure that each coil perforation lines can meet high quality requirements. From the procurement of raw materials, the control of production processes to the commissioning and testing of equipment, every link is strictly controlled to ensure the stability and efficiency of the equipment.

(3) After-sales service

KINGREAL provides a complete after-sales service system to ensure that any problems encountered by customers during equipment installation, commissioning, and operation can be solved in a timely manner. The company provides regular technical training, equipment maintenance, and online support services to ensure that the equipment can operate stably for a long time and maximize production efficiency.