What is the Role of Downspout Machine for Metal Tile Roofing System?

2025-04-20 12:001. Relationship Between Metal Roof Tile System and Downspout Machine

The metal roof tile system is a common roof structure in modern buildings. Common types of metal roof tiles on the market include corrugated roof tiles, standing seam roof tiles, IBR roof tiles and cap ridge tiles. These metal roof tiles not only provide good waterproofness and durability, but also meet the needs of different architectural styles in terms of aesthetics. However, a complete roof tile system not only relies on the design and installation of roof tiles, but also requires an effective drainage system to ensure the smooth discharge of rainwater.

In the metal roof tile system, downspouts play a vital role. Downspout making machines are key equipment for the production of these downspouts. By effectively directing rainwater accumulated on the roof into the downspouts, the downspout making machine ensures that the rainwater can flow smoothly to the drainage system or underground water storage facilities below, thereby avoiding roof damage or leakage caused by water accumulation. It can be seen that the relationship between the metal roof tile system and the downpipe roll forming machine is close and inseparable.

2. Role of Downspout Making Machine in Roof Tile System

The main function of the downpipe roll forming machine is to produce downpipes, which are responsible for guiding rainwater from the roof to the ground or underground drainage system. Its working principle is relatively simple, but it is crucial in practical applications. Specifically, the role of the downspout machine can be analyzed from the following aspects:

1

Rainwater diversion

The main function of the downpipe is to safely divert rainwater accumulated on the roof to the appropriate drainage location. Through reasonable design and installation, the downpipe can effectively prevent rainwater from being retained on the roof, thereby avoiding leakage and water accumulation caused by excessive moisture.

2

Protect the roof structure

Without an effective drainage system, rainwater may cause long-term damage to the roof structure, and even cause problems such as leakage and corrosion. The high-quality downpipes produced by the downspout making machine can effectively prevent these problems from occurring and ensure the overall stability and durability of the roof system.

3

Improve the beauty of the building

Modern buildings pay more and more attention to exterior design, and the shape and color of the downpipe also need to match the architectural style. Downpipe roll forming machines can produce downspouts of different styles and sizes according to customer needs, thereby improving the overall aesthetics of the building.

4

Adapt to different environments

Under different climatic and environmental conditions, the design and material selection of downspouts may vary. Downspout machines can adjust production parameters according to actual needs to meet the use requirements of various environments.

3. Reasons for Large Demand for Downspout Making Machines

The introduction of downspout machines solves several key problems in construction and construction. Here are a few important reasons why the construction industry needs downpipe roll forming machines:

3.1 Improve production efficiency

Traditional downspout manufacturing methods are often time-consuming and inefficient, while the use of downspout making machines can achieve large-scale production. The high degree of automation of the downspout machine can quickly produce a large number of downspouts to meet the needs of construction projects.

3.2 Reduce labor costs

The use of downpipe roll forming machines can significantly reduce labor costs. Traditional manufacturing methods require a lot of manual intervention, while modern downspout machines reduce dependence on manual labor through automated production and reduce overall production costs.

3.3 Guarantee product quality

Downspout making machines can ensure that the size and shape of each downpipe meet the standards, which is very important for subsequent installation and use. The high-precision production process can effectively reduce installation problems caused by inappropriate sizes.

3.4 Flexible customization capabilities

Downpipe roll forming machines can produce downpipes of different types and sizes according to customer needs. This flexible customization capability allows builders to choose the right product according to the specific requirements of the project, improving the adaptability of construction.

3.5 Adapt to a variety of materials

Downspout making machines can handle a variety of metal materials, including steel, aluminum, and semi-hard copper. This feature allows manufacturers to choose the right raw materials according to different application requirements, thereby improving the durability and performance of the product.

4. Advantages of Downpipe Roll Forming Machines

Downspout making machines have many advantages in the modern construction industry. The following are some of the main advantages:

4.1 Diverse product selection

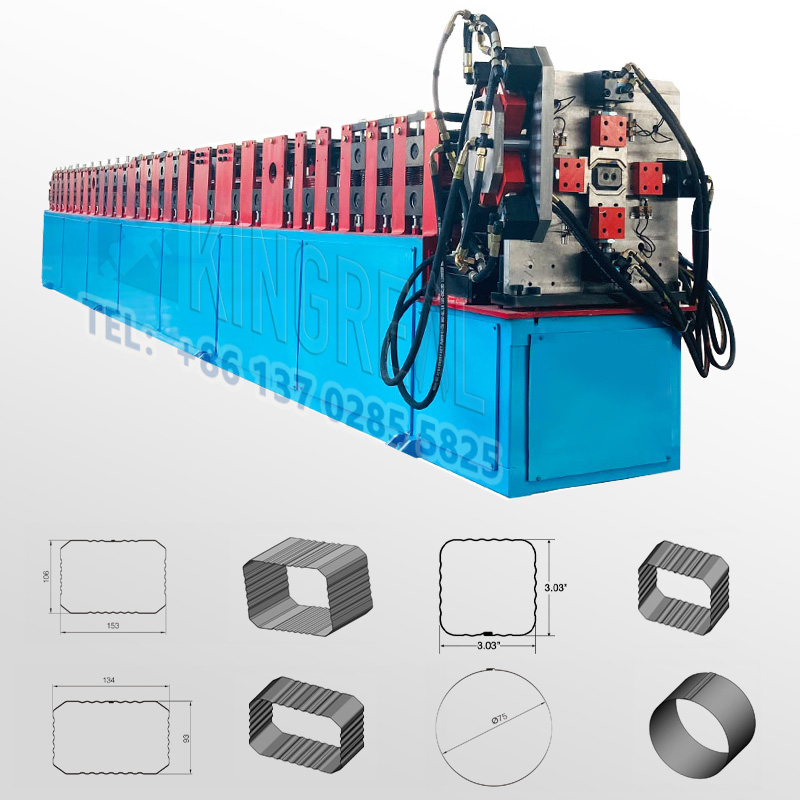

Downspout machines can produce circular and rectangular downpipes of different types and sizes. According to the needs of the construction project, customers can choose the most suitable type of downpipe. This flexibility enables the downspout making machine to be widely used in various architectural styles and structures.

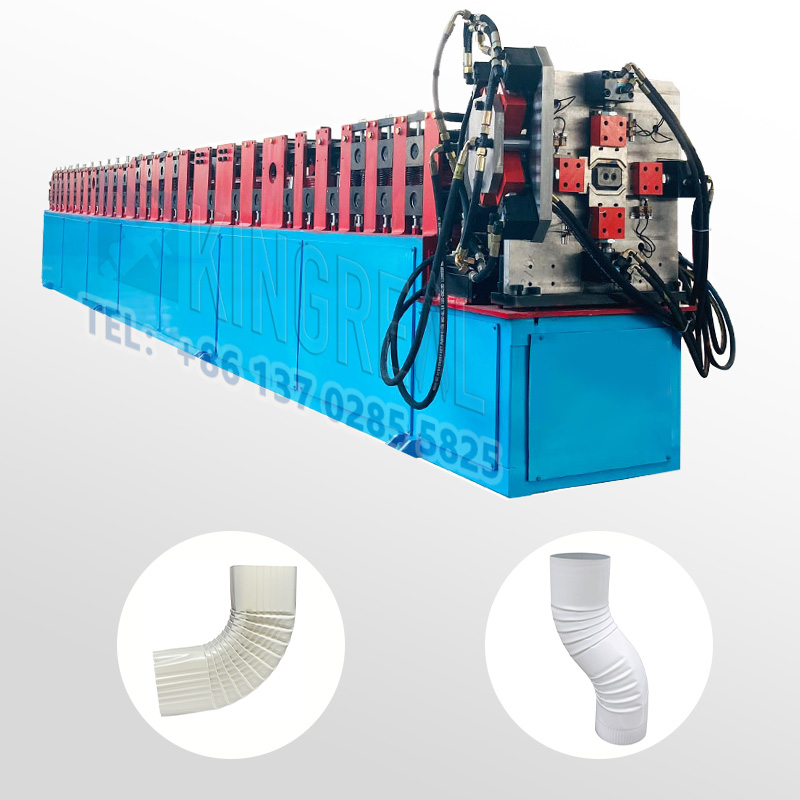

4.2 High Precision and Seamless Design

KINGREAL downpipe roll forming machines are well known for their high precision and seamless products. The seamless design not only enhances the aesthetics of the product, but also effectively prevents rainwater leakage, ensuring that rainwater can safely flow into the underground drainage system. This advantage is particularly important in construction projects that require high waterproof performance.

4.3 Processing a variety of metal materials

Downpipe roll forming machines are able to process a variety of metal materials, including steel, aluminum, and semi-hard copper. This flexibility allows manufacturers to choose the right material according to customer needs, thereby improving the durability and applicability of the product. For example, aluminum downpipes are often used in residential and commercial buildings due to their lightness and corrosion resistance, while steel downpipes are suitable for industrial buildings due to their strength and durability.

4.4 Reliable After-Sales Service

KINGREAL provides comprehensive after-sales service to ensure that customers can get timely technical support and maintenance services during the use of downpipe roll forming machines. This service not only improves customer satisfaction, but also enhances the brand's credibility.

4.5 Environmental protection and sustainable development

With the increasing awareness of environmental protection, the construction industry pays more and more attention to sustainable development. Downspout making machines can produce recyclable metal downpipes, which meet the environmental protection requirements of modern buildings. This feature makes construction projects using downpipe roll forming machines more competitive in the market.