What are the applications of solar mounting strut channel machines?

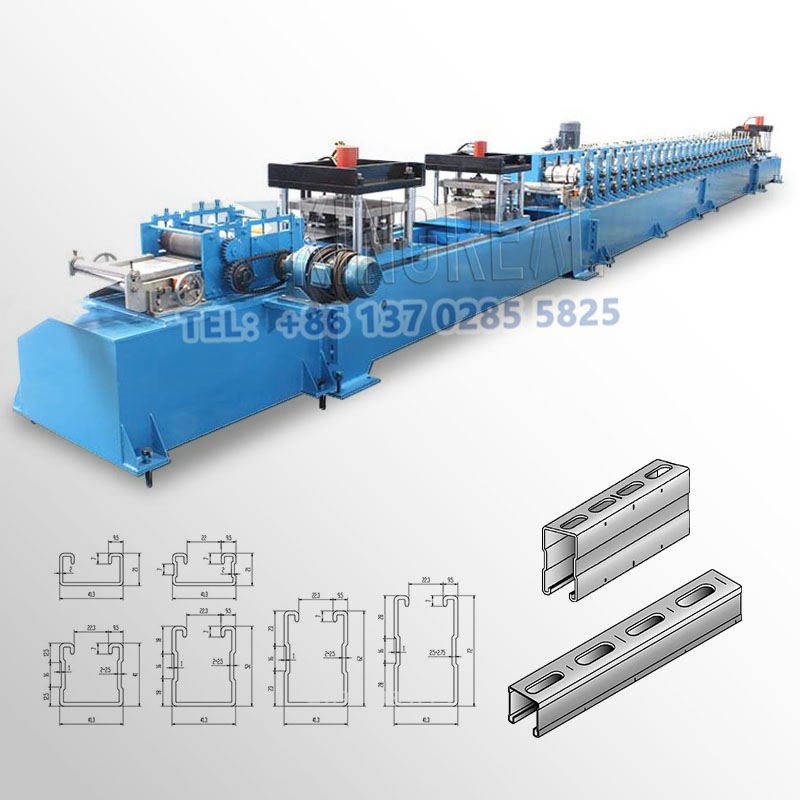

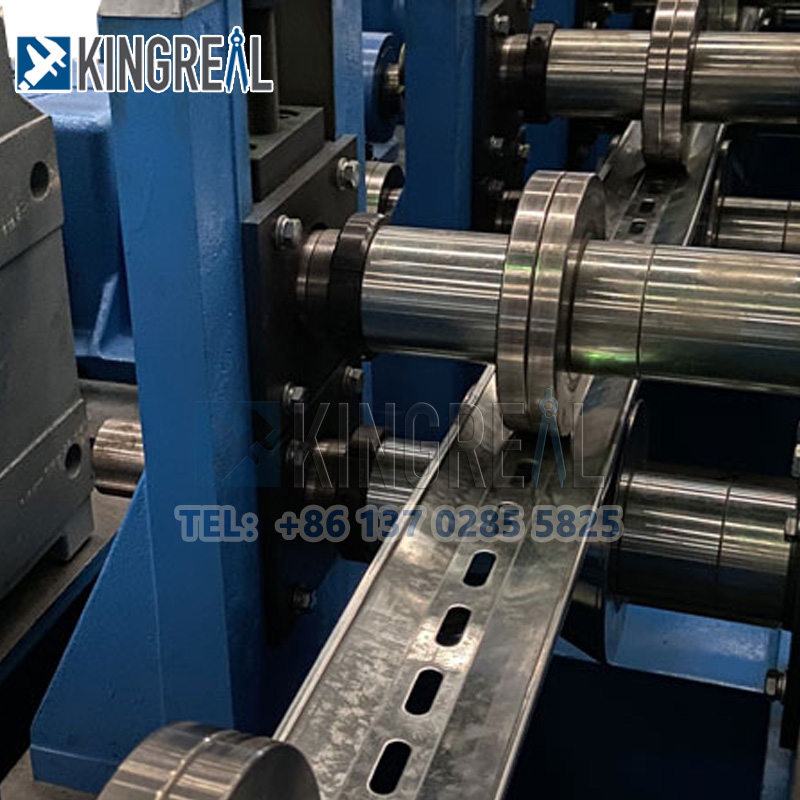

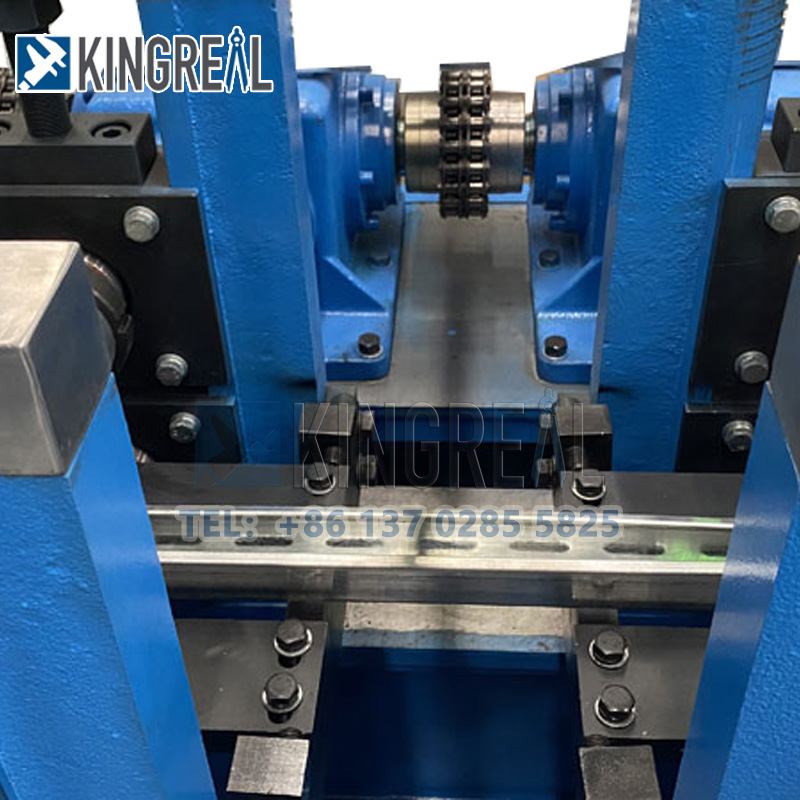

2025-04-15 12:00KINGREAL solar mounting strut channel machine is a kind of equipment specially used for manufacturing solar mounting strut channel for solar panel installation. It produces solar mounting strut channels that meet various installation requirements by bending, cutting and forming metal strips. These pv support brackets are not only used to support solar panels, but also provide stable support in different environments and installation conditions. The design of solar mounting strut channel roll forming machine is to improve production efficiency and reduce costs, thereby promoting the rapid development of the photovoltaic industry.

Modern solar mounting strut channel production lines usually adopt advanced roll forming technology, which has the advantages of high efficiency, precision and flexibility. By using solar mounting strut channel machines, manufacturers can customize unistrut channels of different specifications and shapes according to customer needs to meet the market demand for diversified products. The wide application of this solar mounting strut channel production line has promoted the development of the photovoltaic industry and provided a solid foundation for the use of renewable energy.

Application of solar mounting strut channel machine

KINGREAL solar mounting strut channel roll forming machine plays an important role in the solar industry and its application fields are very wide. The following is a detailed discussion of the main application fields to show the importance and practical application value of solar mounting strut channel production line.

1. Rooftop solar system

In modern buildings, rooftop solar system is one of the most common photovoltaic applications. Whether it is a residential or commercial building, rooftop brackets provide a solid foundation for solar panels, ensuring their stability in various climate conditions. Brackets produced using solar mounting strut channel production lines have the following advantages:

1.1 Adapt to different roof types

Roofs come in a variety of shapes and structures, including flat roofs, pitched roofs, and curved roofs. Solar mounting strut channel roll forming machines are able to customize pv support brackets according to different types of roofs to meet their specific installation needs. For example, the bracket design for flat roofs is usually simpler, emphasizing lightweight and low wind resistance to reduce the burden on the building itself. For pitched roofs, the brackets need to have stronger wind resistance to ensure safety in strong winds.

1.2 Consider climate factors

The design of rooftop solar systems also needs to consider local climate conditions. For areas with strong winds, the bracket design needs to enhance stability, and more solid materials and structures may be used. In areas with extremely high or low temperatures, the material selection of the bracket also needs to consider temperature resistance to ensure stability and safety in long-term use.

1.3 Ease of installation

The design of rooftop brackets also needs to consider the ease of installation. The brackets produced by solar mounting strut channel machines are usually designed with modular structures, making the installation process easier and reducing construction time and costs. This modular design also facilitates later maintenance and replacement, improving the overall efficiency of the system.

2. Ground-mounted solar farms

Ground-mounted solar farms are an important part of large-scale renewable energy projects, which usually require a large number of brackets to support solar panels. The application of solar mounting strut channel roll forming machines in this field is mainly reflected in the following aspects:

2.1 Strength and durability

Ground brackets must have extremely high strength and durability to withstand wind loads, snow loads and other environmental factors. The brackets produced by solar mounting strut channel production lines are usually made of high-strength galvanized steel or aluminum alloy materials, which can ensure the stability of the brackets in severe weather conditions and extend their service life.

2.2 Optimal installation angle

The design of ground brackets usually takes into account the optimal installation angle of the panels to maximize power generation. By adjusting the tilt angle of the bracket, the power plant can maintain the optimal reception efficiency of solar energy in different seasons and weather conditions. The flexibility of solar mounting strut channel roll forming machines makes this customized design possible.

2.3 Installation efficiency

Efficient installation is the key to the success of ground-based solar farms. The modular design and prefabricated components of the solar mounting strut channel production line can significantly shorten the installation time and reduce labor costs. In large-scale projects, this efficiency improvement can bring significant economic benefits.

3. Floating solar system

As the use of water resources has gained more and more attention, floating solar systems are gradually becoming an emerging photovoltaic application model. The bracket design of this type of system is significantly different from that of traditional ground brackets, which is mainly reflected in the following aspects:

3.1 Material selection

Floating brackets are usually made of lightweight, corrosion-resistant materials such as plastic or aluminum alloy. These materials can effectively resist the erosion of the water environment and ensure the long-term stability of the bracket. The solar mounting strut channel roll forming machine can support the processing of a variety of materials to meet the special requirements of floating brackets for materials.

3.2 Water wave resistance

Floating solar systems need to have good water wave resistance to ensure that the panels remain stable even under the influence of waves or wind. The bracket design needs to take into account the dynamic characteristics of water to ensure that the bracket can be firmly fixed on the water surface to avoid displacement caused by water flow or waves.

3.3 Ecological Benefits

Floating solar energy systems not only utilize water resources, but also reduce evaporation and algae growth in water bodies, and have good ecological benefits. The environmentally friendly design of the solar mounting strut channel production line makes this system also have advantages in environmental protection.

4. Solar carports

Solar carports are an innovative application that combines parking facilities with solar power generation, and are increasingly appearing in cities and commercial areas. The bracket design in this application field highlights the following features:

4.1 Beautiful structure

Solar carports must not only be practical, but also aesthetically pleasing. The solar mounting strut channel roll forming machine can produce brackets with elegant appearance and reasonable structure to enhance the overall visual effect of the carport and attract more users.

4.2 Versatility

In addition to the power generation function, the solar carport also needs to provide multiple functions such as parking, shading and protection. The design of the bracket must take these functions into account to ensure that the vehicle is fully protected under the carport. The flexibility of the solar mounting strut channel production line allows designers to customize according to actual needs.

4.3 Safety

The bracket design of the carport needs to ensure safety in various weather conditions, especially in strong winds or snowy weather. By using high-strength materials and reasonable structural design, the photovoltaic bracket can effectively enhance the wind and snow resistance of the carport and ensure the safety of users.

5. Off-grid solar energy solutions

In remote areas or areas where the power grid cannot cover, off-grid solar energy solutions have become an important way to supply electricity. The application of solar mounting strut channel production lines in this field is mainly reflected in the following aspects:

5.1 Strong adaptability

The bracket design of the off-grid system needs to adapt to different terrain and environmental conditions. The solar mounting strut channel roll forming machine can flexibly adjust the design and production of the bracket according to the needs of the specific site to ensure its stability and safety in various environments.

5.2 Convenient transportation and installation

In remote areas, the convenience of transportation and installation is crucial. The modular design of the solar mounting strut channel production line allows the bracket to be easily disassembled and transported, reducing transportation costs and simplifying the installation process. This convenience can effectively improve the deployment efficiency of the off-grid system.

5.3 Reliable power supply

The successful operation of off-grid solar energy systems depends on the stability of the bracket and the effective installation of the panels. By using high-quality photovoltaic brackets, users can ensure the reliability of their systems in long-term use and provide continuous power support for homes, communication towers, etc.