Commonly Used Materials for Aluminum Ceiling Panels

2024-09-13 11:10Video About Aluminium Ceiling Tiles Machine

Everyone knows that aluminum ceiling panel is the most commonly used building material for decorative ceilings. Although aluminum is used as the raw material, there are differences. Generally, the aluminum raw materials for suspended ceilings on the market are aluminum alloys, not just pure aluminum, because the content of aluminum alloy is different, the characteristics of aluminum alloy products are also different. Since aluminum has many good properties, it is very popular in the market, and many manufacturers choose to purchase Full Automatic Metal Ceiling Production Line from Kingreal to increase their production.

Three Types Of Aluminum Alloy

In the current aluminum ceiling material market, aluminum alloy is roughly divided into 3 types:

The first type: aluminum-magnesium alloy, which is made of aluminum as the main component and contains part of manganese. The characteristic of aluminum-magnesium alloy is that the raw material has good oxidation resistance. Because it contains manganese, it also has certain compressive strength and Bending stiffness, this has become the most ideal alloy material for aluminum ceiling panels.

The second type: aluminum-manganese alloy. As the name suggests, manganese is used as the raw material of aluminum alloy. The compressive strength and bending stiffness of this raw material are slightly better than that of aluminum-magnesium alloy, but the oxidation resistance is slightly lower than that of aluminum-magnesium alloy.

The third type: aluminum alloy, which contains less manganese and magnesium. Therefore, its compressive strength and bending stiffness are significantly smaller than aluminum-magnesium alloy and aluminum-manganese-aluminum alloy. Because of its low content of manganese and magnesium elements, the strength properties of aluminum alloys are relatively soft, which is conducive to production and processing, but it is also used in some specific projects.

Advantages Of KINGREAL Aluminium Ceiling Tiles Machine

As a leading enterprise in the ceiling manufacturing industry, KINGREAL's metal ceiling machine is well-known for its multiple advantages, covering the entire process from raw material processing to finished product manufacturing. These advantages not only make KINGREAL's products stand out in the market, but also provide customers with more comprehensive and flexible solutions. The following are several major advantages of KINGREAL aluminium ceiling tiles machine:

1. Diversified raw material processing capabilities

KINGREAL's aluminium ceiling tiles machine is able to efficiently process and manufacture a variety of metal raw materials, including galvanized iron coils, aluminum coils, and roll-coated coils. This diversified raw material adaptability allows customers to choose the most suitable material according to their needs. Galvanized iron coils are widely favored for their excellent corrosion resistance and economy, aluminum coils are suitable for high-end ceilings due to their light weight and easy processing characteristics, and roll-coated coils provide rich colors and decorative effects to meet different aesthetic needs.

In actual production, KINGREAL engineers will adjust the production parameters of the metal ceiling production line according to the different characteristics of the materials to ensure the best performance of each material during the processing process. This flexibility not only improves production efficiency, but also ensures the quality of the final product and meets the needs of different customers.

2. Diverse ceiling sizes

KINGREAL's metal ceiling production line has the ability to produce ceilings of different sizes, including 600x600mm, 300x300mm, and 600x1200mm. This flexible size selection allows customers to customize according to the specific requirements of the project. More importantly, KINGREAL's metal ceiling production line supports the manufacture of ceilings of different specifications on the same production line, which greatly improves the flexibility and efficiency of production.

Customers only need to submit their design drawings to KINGREAL's engineers, and the team will tailor the parameters of the metal ceiling production line for you according to the drawings. This personalized service not only improves customer satisfaction, but also ensures the adaptability of the product in practical applications.

3. A variety of types of ceilings to choose from

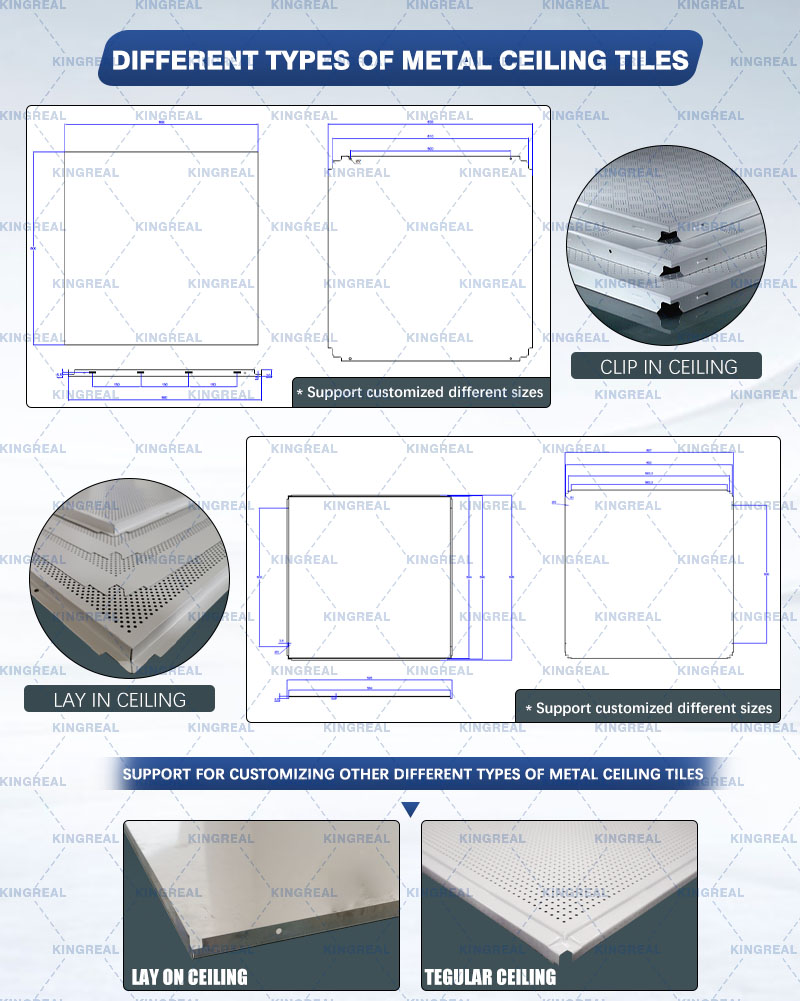

In terms of the type of ceiling, KINGREAL's metal ceiling production line can manufacture a variety of types of ceilings, including clip-in, lay-in, and tegular. These different types of ceilings are suitable for a variety of different places and needs.

- Clip in ceiling: This type of ceiling is easy to install and replace, and is suitable for occasions that require frequent maintenance, such as offices and commercial spaces.

- Lay in ceilings: provide a smoother visual effect, suitable for aesthetically pleasing environments such as high-end hotels and residences.

- Tegular ceilings: can create a more layered spatial experience, suitable for places with high artistic and design requirements.

This variety of product types allows KINGREAL to better meet the specific needs of customers and provide more targeted solutions.

4. Flexible production solutions

In order to meet the needs of different customers, KINGREAL provides a variety of production solutions. In addition to the fully automatic metal ceiling production line, KINGREAL can also provide customers with semi-automatic metal ceiling production lines. This flexibility allows customers to choose according to their own production capacity and budget.

For those companies that are just starting out, semi-automatic metal ceiling machines can effectively reduce the initial investment risk. When the production scale gradually expands, KINGREAL can also provide customers with upgrade services to transform semi-automatic metal ceiling production lines into fully automatic metal ceiling production lines. This gradual investment method allows customers to gradually improve the level of equipment without affecting production capacity.

High-precision Metal Ceiling

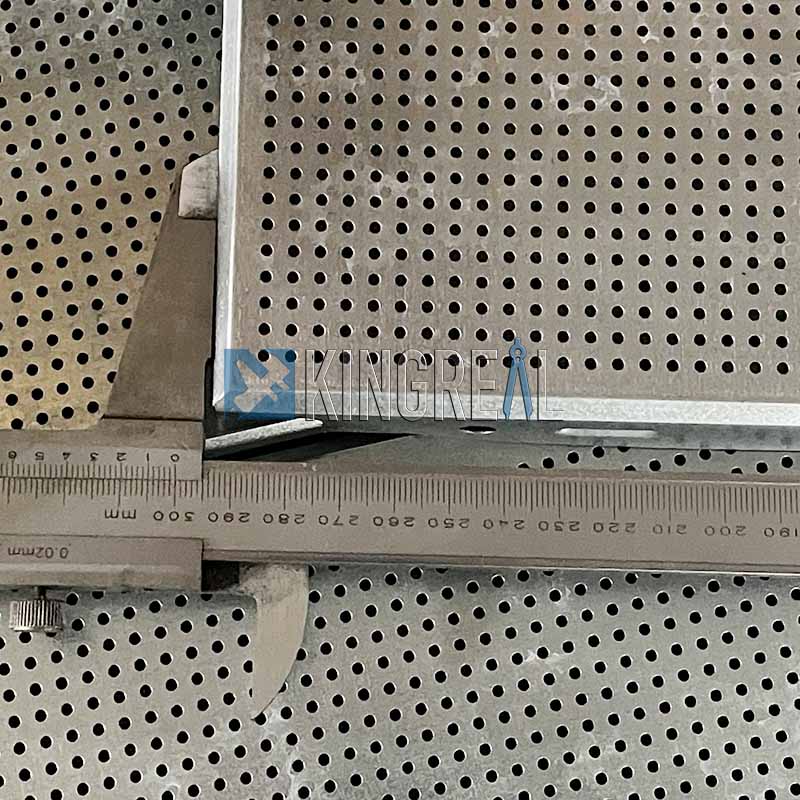

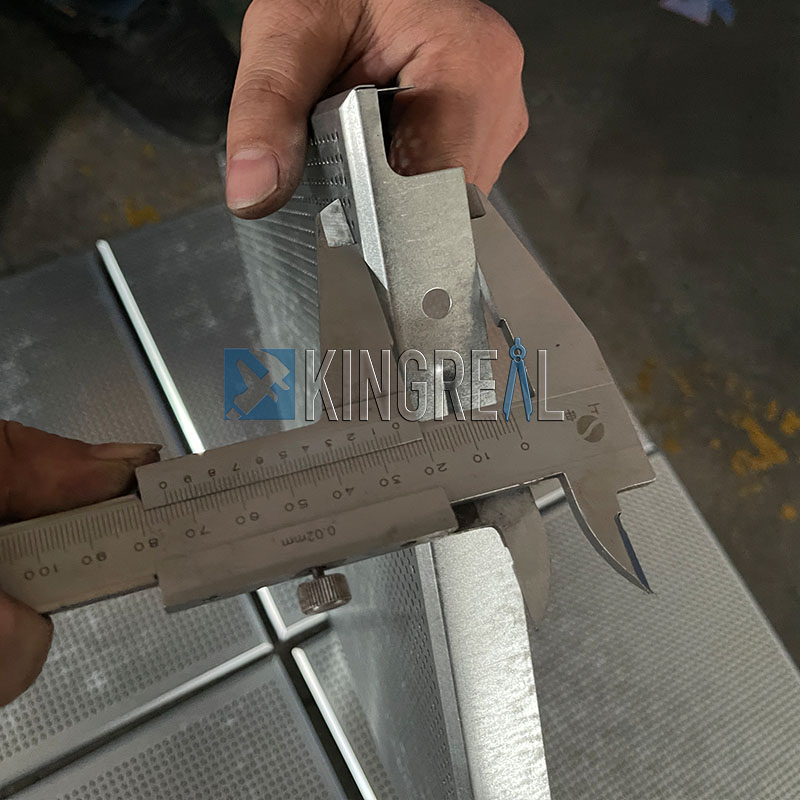

KINGREAL strictly controls every link in the manufacturing process of metal ceiling machines to ensure that product quality is always in the leading position in the industry. The parts equipped in the metal ceiling production line are all well-known brands, and the selected raw materials have high strength and excellent processing performance. These factors work together to make the ceilings produced by KINGREAL excellent in precision and consistency.

Specifically, the precision error range of KINGREAL ceilings does not exceed ±0.1mm, which means that each ceiling can strictly meet the design requirements in size. In addition, the surface treatment process of the ceiling ensures that the product is burr-free when it leaves the factory, with good surface smoothness and consistency. This high-precision product not only improves the customer's experience, but also establishes a good reputation in the market.

Precautions for purchasing aluminum ceiling tile

1.When purchasing, you need to check by appearance whether the surface of the aluminum clip-in tile is flat. If it is uneven, it is best not to buy it.

2.At the same time, you can also check whether the surface of the aluminum clip-in ceiling tile is smooth by touching it with your hands. If it is not smooth but has a rough feel, it means that the quality of the aluminum clip-in ceiling tile is relatively poor.

If you want to get more information about aluminum ceiling panels, please do not hesitate to contact us!