How to use baffle ceiling machine?

2025-01-12 14:17Definition of baffle ceiling production line

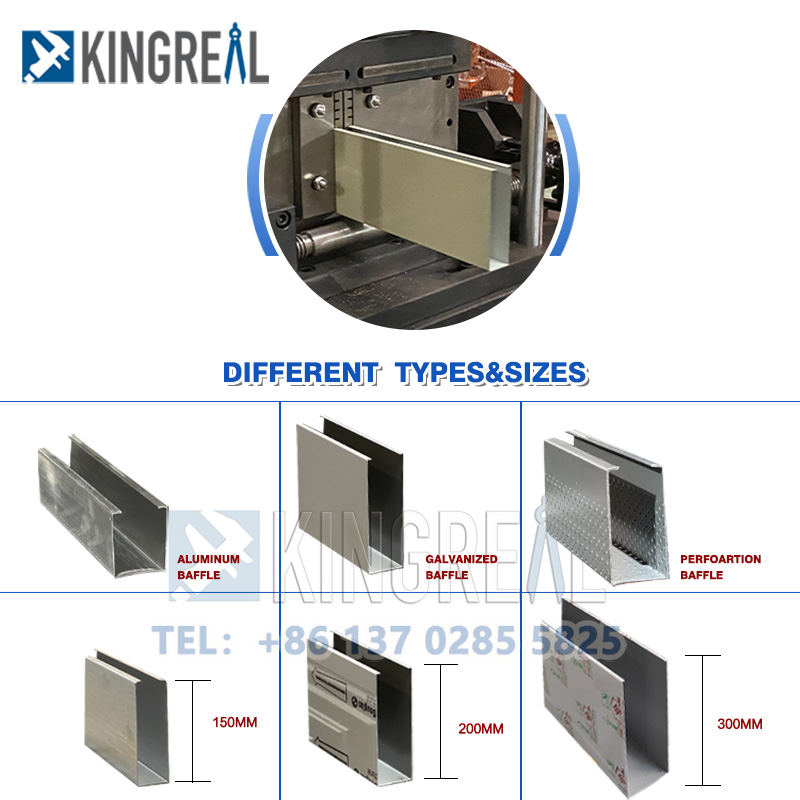

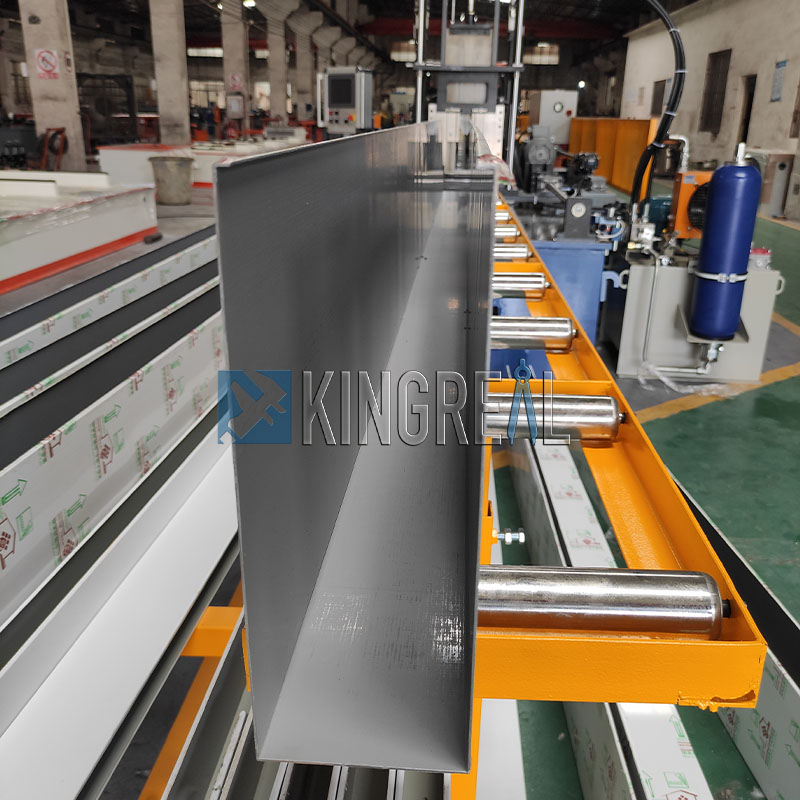

The baffle ceiling machine is used to produce U-shaped baffle ceilings at high speeds of up to 30m/min. The baffle ceiling production line mainly uses aluminum strip as raw material. After uncoiling, leveling, continuous rolling cold bending, and fixed-length cutting, it can produce U-shaped baffles of any size within the design range.

The width and height of the U-shaped baffle profile can be adjusted electrically. The operator only needs to input the width, height, and length of the product on the touch screen, and the baffle ceiling production line will automatically produce it, and the specifications can be changed within a few minutes.

Main Components of baffle ceiling machine

The baffle ceiling machine is mainly composed of precision components such as decoiler, precision straightener, main roll forming machine, hydraulic cutting machine, output table and electrical control panel.

Operation steps of the baffle ceiling production line

Before operating the baffle ceiling machine, the operator should understand the structure and operation process of the machine in detail, and ensure that all operation links meet safety requirements. The following are the detailed steps for operating the baffle ceiling machine:

1. Preparation before starting the machine

Before starting the baffle ceiling production line, it is very important to perform some basic inspections and preparations. The specific steps are as follows:

(1) Check the electrical control panel: Make sure that all functions on the electrical control panel are normal, especially the power switch, start button and emergency stop button. Check for overload, short circuit and other faults.

(2) Check the oil pressure system: The hydraulic cutting machine requires normal oil pressure support. Before starting the machine, check whether the hydraulic oil reaches the normal level, whether the oil pipe connection is tight, and whether the oil pump works normally.

(3) Check the decoiler and coil: Make sure that the surface of the coil is flat and there is no obvious damage. Put the metal coil into the decoiler and adjust the tension of the coil to avoid loosening or tightening the coil, which will affect subsequent processing.

(4) Check the straightener and rollers: Make sure that the rollers of the precision straightener and roll forming machine are not worn, deformed or damaged, clean the working area of the rollers and leveler, and make sure there are no obstacles.

(5) Check the cutting system: The hydraulic cutter should be kept sharp and precise. Check whether the blade is sharp and the workbench is clean to avoid errors during cutting.

2. Start the baffle ceiling machine

The operation process of starting the baffle ceiling machine includes:

(1) Start the power supply: According to the instructions on the electrical control panel, press the start button to turn on the power of the machine. Check whether all electrical components are working properly and ensure that the control panel display is normal.

(2) Adjust the decoiler: After starting, adjust the tension device of the decoiler to feed the metal coil into the precision leveler. By adjusting the tension of the decoiler, you can ensure that the coil does not deviate and avoid problems with feeding.

(3) Adjust the leveler: Adjust the pressure and speed of the precision leveler so that it can completely level the coil. If there are more serious bending or wrinkling problems, the pressure can be increased appropriately, but excessive squeezing should be avoided.

(4) Adjust the roll forming machine: According to the specifications of the required baffle ceiling, adjust the gap between the roll forming machine rollers. This step is critical. Too large a gap will cause irregular forming of the baffle, and too small a gap may cause the metal sheet to break or deform.

(5) Start the hydraulic cutter: According to the required baffle ceiling length of production, set the cutting system. The accuracy and cutting speed of the hydraulic cutter should match the working speed of the roll forming machine.

3. Monitoring during production

During the production process, the operator needs to continuously monitor the operating status of the machine to ensure that each link is smooth. The specific operations are as follows:

(1) Monitor material feeding: Ensure that the coil flows smoothly between the decoiler and the leveler without jamming or offset. Any irregular feeding will affect the stability of subsequent production.

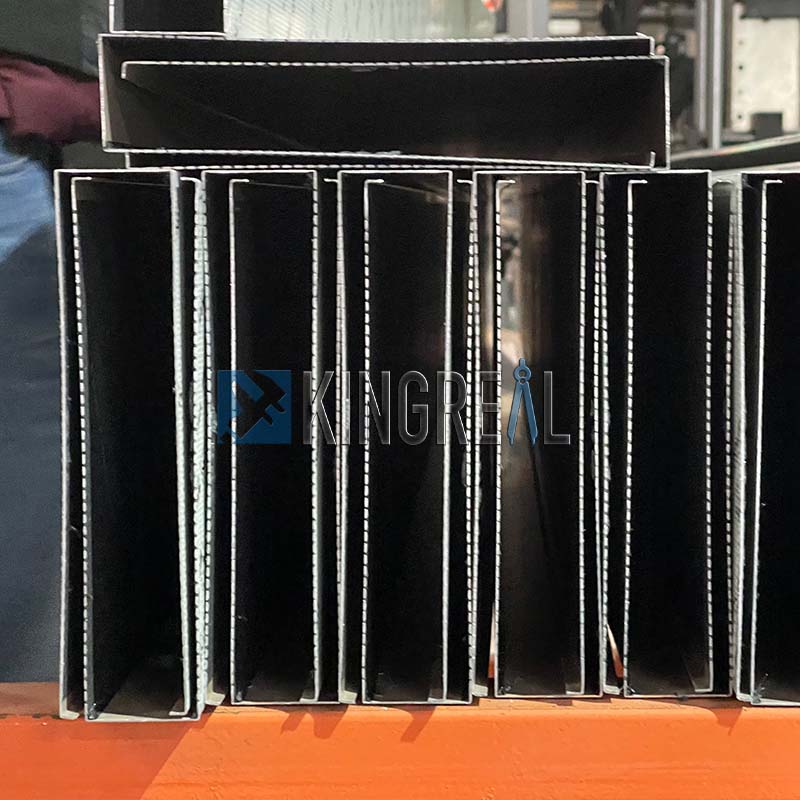

(2) Real-time inspection of forming quality: During the roll forming process, regularly check the shape and size of the u baffle. If the forming quality is found to be poor, immediately adjust the gap or pressure of the rollers to ensure that the quality of each u baffle ceiling meets the requirements.

(3) Control the cutting length: When producing a certain length of baffle ceiling, the cutting accuracy should be checked to ensure that the length adjustment function of the cutting station is normal. If deviation is found, the machine should be stopped immediately and the cutting system should be adjusted.

(4) Clean up the waste: Some waste will be generated during the production process. The operator should clean up the waste in time to prevent clogging the equipment or affecting the production process.

(5) Check the output table: After the square tube is output from the hydraulic cutting station, it should be transferred to the subsequent processing area through the output table to ensure that the finished product is smoothly output and will not collide with other products.

4. Shutdown operation

After completing the production task, the operator needs to perform the shutdown operation to ensure that the machine is in a safe state. The specific steps are as follows:

(1) Check before shutdown: Before shutdown, check whether the equipment has stopped running completely to ensure that there is no material stuck or machine failure.

(2) Turn off the power: Turn off the power on the electrical control panel to stop the power supply.

(3) Clean the equipment: clean the metal chips and waste on the roll forming machine, leveling machine, hydraulic cutting machine and other equipment to keep the equipment clean and avoid affecting the next use of the machine.

(4) Check the hydraulic system: check the oil level and pressure of the hydraulic oil to ensure that the hydraulic system is normal and do a good job of subsequent maintenance.

(5) Keep records: record the working status of the machine during the production process, any faults, the machine's operating time and other information for future inspection and maintenance.