What Are Metal Ceiling Tiles?

2024-11-13 16:49"Metal ceiling tiles are becoming increasingly popular in modern architecture and interior design. Not only do they offer a sleek, modern look, but they also offer the benefits of durability and easy maintenance. This article will detail the types, benefits, installation methods and maintenance tips to help you understand why metal ceiling tiles are the perfect choice for your next project."

What Are The Metal Ceiling Tiles?

Metal ceiling tiles produced by metal ceiling machine which are panels made of various metals such as aluminum, steel, and tin that are used to create decorative and functional ceiling surfaces. These tiles are available in a variety of finishes and patterns to suit different design styles.

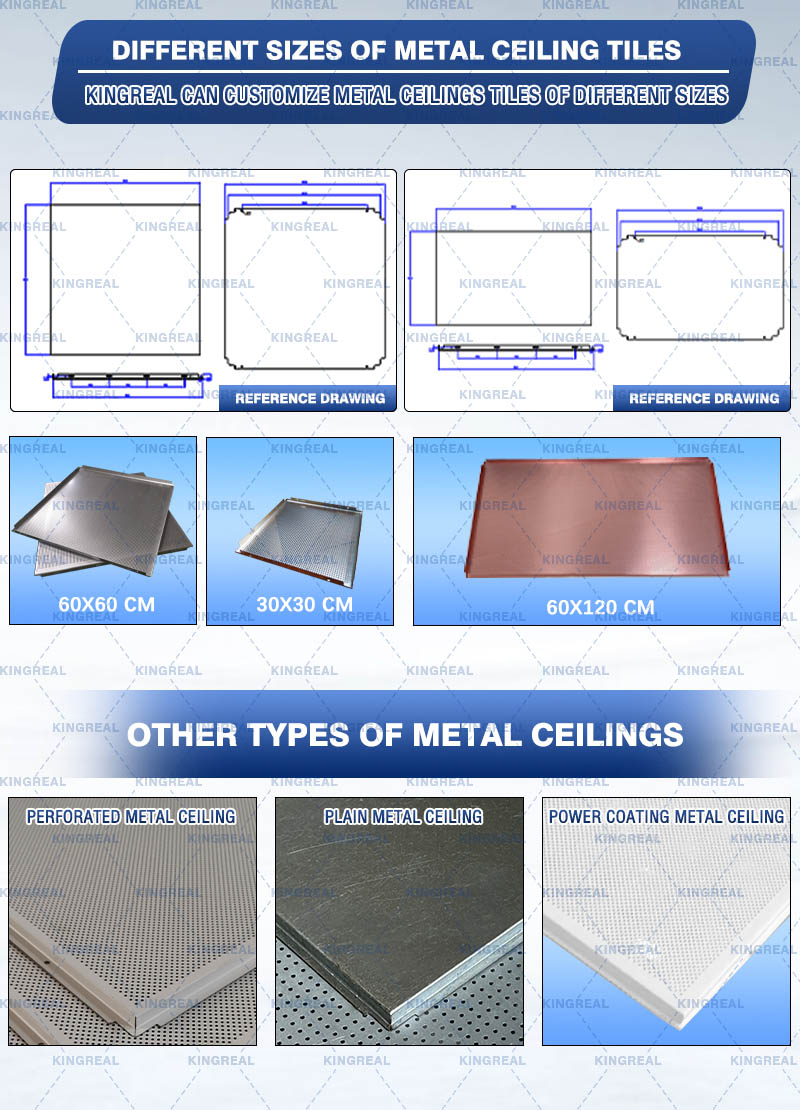

Types of Metal Ceiling Tiles

There are several common types of metal ceiling tiles on the market, each with unique features and benefits:

1. Aluminum ceiling tiles

Aluminum ceiling tiles are lightweight, corrosion-resistant, easy to install, and suitable for high humidity areas such as kitchens and bathrooms.

2. steel ceiling tiles

Steel ceiling tiles are known for their strength and durability. They are usually used in commercial spaces and industrial applications and can withstand heavy loads.

3. Tin ceiling tiles

Tin ceiling tiles have a classic and elegant look. They are commonly used in the restoration of historic buildings and vintage style designs.

How To Manufacturing Metal Ceiling Tile?

"The production process of metal ceiling tiles production line involves several key steps to ensure the quality and consistency of the final product. Here’s a detailed overview of the production process"

1. Decoiler : The metal coil is unrolled and prepared for processing. The decoiler machine ensures that the large metal sheet is ready for the next steps.

2. Leveling: The metal sheet is leveled to ensure flatness. A leveling machine is used to remove any bends or waves from the metal sheet.

3. Servo Feeder : The leveled metal sheet is fed into the next processing station. Precise control by the feeder machine ensures the material moves at a consistent speed for subsequent operations.

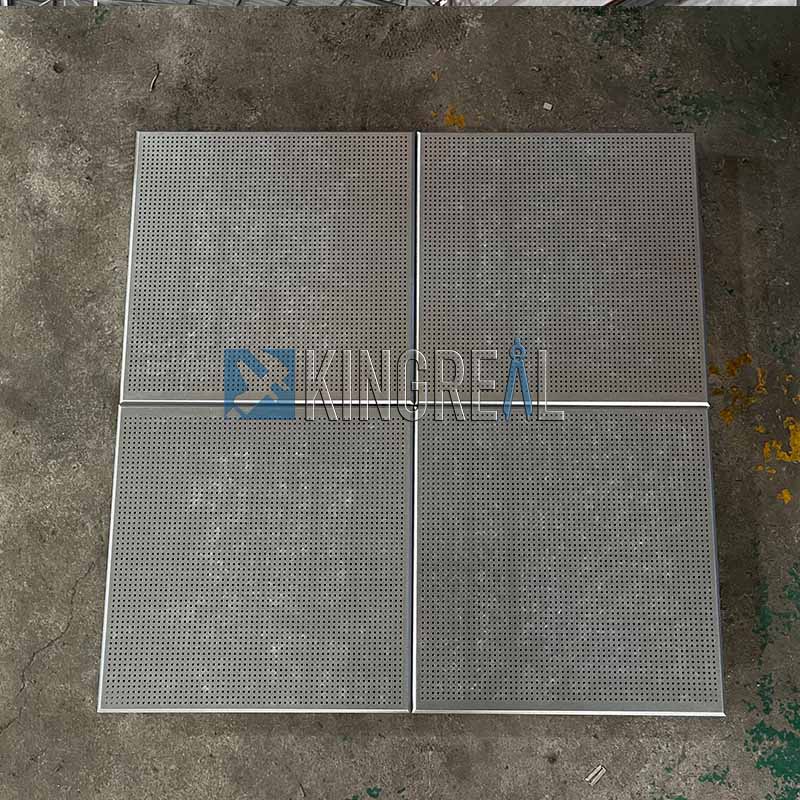

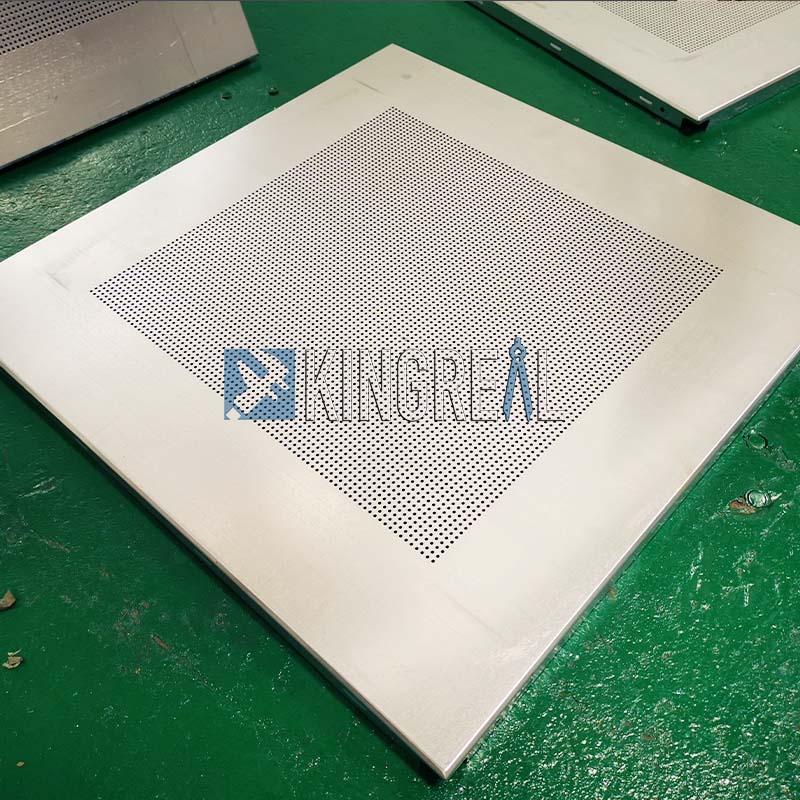

4. High Precision Perforated : Holes are punched into the metal sheet as per design requirements. This step is carried out using a punching machine, and the size and location of the holes can be customized.

5. Corner Cutting: The edges of the metal sheet are trimmed to fit specific installation requirements. This process is performed by a corner cutting machine to ensure each tile has neat and uniform edges.

6. Secondary Leveling: The metal sheet undergoes a second leveling process to ensure final flatness before forming.

7. Hydraulic Forming: The metal sheet is pressed into the desired ceiling tile shape and texture using a hydraulic forming machine. This critical step defines the final appearance and structure of the ceiling tiles.

8. Discharging: The formed metal ceiling tiles are ejected from the production line and undergo initial inspection and packaging. Finished products are then sent to storage or directly to distribution and installation.

These steps ensure high-quality and consistent metal ceiling tiles that meet the demands of various construction and renovation projects. Throughout each production stage, precise control and rigorous quality checks are essential to meet customer expectations and industry standards.

Video About Metal Ceiling Tile Production Line

What Is The Advantages Of Metal Ceiling Tile?

Metal ceiling tiles are highly durable, able to stay in place for years without showing signs of wear and tear. They are moisture-, fire- and insect-resistant, making them suitable for a variety of environments.

Metal ceiling tiles are available in a variety of finishes, colors and patterns to enhance the aesthetic appeal of any space. They can be used to create a modern, industrial or classic look. Metal ceiling tiles are easy to clean and maintain. Unlike traditional ceiling materials, they do not require frequent painting or sealing treatments.

How To Maintain The Metal Ceiling Tile?

Clean tiles regularly with a damp cloth or mild detergent to remove dust and dirt. Avoid using strong chemicals or abrasives, which may damage the finish. Regularly inspect your tiles for any signs of damage, such as dents or scratches. Address any issues promptly to prevent further deterioration.

Consider applying a protective coating to enhance the tiles' resistance to moisture and corrosion. This helps to extend the life of your metal ceiling tiles.

What Is The Industry Developments Of Ceiling Tile?

The Metal Ceiling Tiles industry has witnessed significant growth in recent years, mainly due to the rapid growth of the construction industry and the demand for efficient and precise building materials.

Metal ceiling tiles are playing an increasingly important role in modern construction and are popular for their durability, aesthetics and ease of maintenance. Metal ceiling tiles are also becoming a popular choice in the market as the demand for environmentally friendly and sustainable building materials increases.

As technology continues to advance, so does the design and manufacturing process of metal ceiling tiles. Modern manufacturing equipment and processes not only improve production efficiency, but also enhance the quality and diversity of products.

Environmental protection and energy saving are the main trends in the current building materials industry. The manufacturing process of Metal Ceiling Tiles is gradually adopting renewable energy sources and eco-friendly materials to minimize the environmental impact. Some of the major challenges faced by the metal ceiling tiles industry include increased competition in the market, volatile raw material prices, and stringent environmental regulations. Suppliers need to continuously innovate and improve product quality to remain competitive in the market.

Other Type Of Ceiling Tiles

1. Gypsum board ceilings are widely used in residential, office and commercial buildings, and are particularly suitable for interior decoration. Due to its light weight, easy installation and good sound insulation, plasterboard has become one of the preferred materials for interior ceilings. Its thickness is generally between 9mm and 15mm, with a common thickness of 12mm.

2. PVC ceiling has the characteristics of waterproof, moisture-proof, anti-insects, suitable for bathrooms, kitchens and other high humidity environments. Its easy-to-clean characteristics also make it useful in places that require high cleanliness, such as hospitals and laboratories.

3. Mineral wool panel ceilings have excellent sound-absorbing properties and are commonly used in offices, conference rooms and schools where noise control is required. In addition, the fire resistance of mineral wool panels makes them an ideal choice for ceiling materials in public buildings.

Ceilings made of different materials have their own characteristics in terms of thickness and range of applications. When choosing ceiling materials, it is necessary to consider factors such as physical properties, appearance effect and installation and maintenance of the materials according to the specific use environment and needs in order to choose the most suitable material. Gypsum board is suitable for general interior decoration, metal ceilings are suitable for industrial and high-end commercial places, and PVC ceilings are the best choice for humid environments