How to add a logo for false ceiling channel machine?

2025-03-29 12:00False ceiling channel is produced by u channel machine, furring channel machine or other false ceiling channel machine. With the widespread application of false ceiling channels in the construction industry, the market demand for false ceiling channels is growing. However, facing the fiercely competitive market, major false ceiling channel manufacturers are thinking about how to improve product differentiation and customization to meet the personalized needs of customers. They urgently need a u channel machine that can solve this problem. In this context, how to effectively set a logo in the production process of false ceiling channels has become an important and worthy topic.

Based on the production needs of customers and market research, KINGREAL engineers have designed a convenient and effective method to engrave the customer-specified logo on the false ceiling channel during the production process of the u channel machine. In response to different needs, engineers have proposed two solutions for customers to choose from, ensuring that customers can make flexible choices based on their actual conditions.

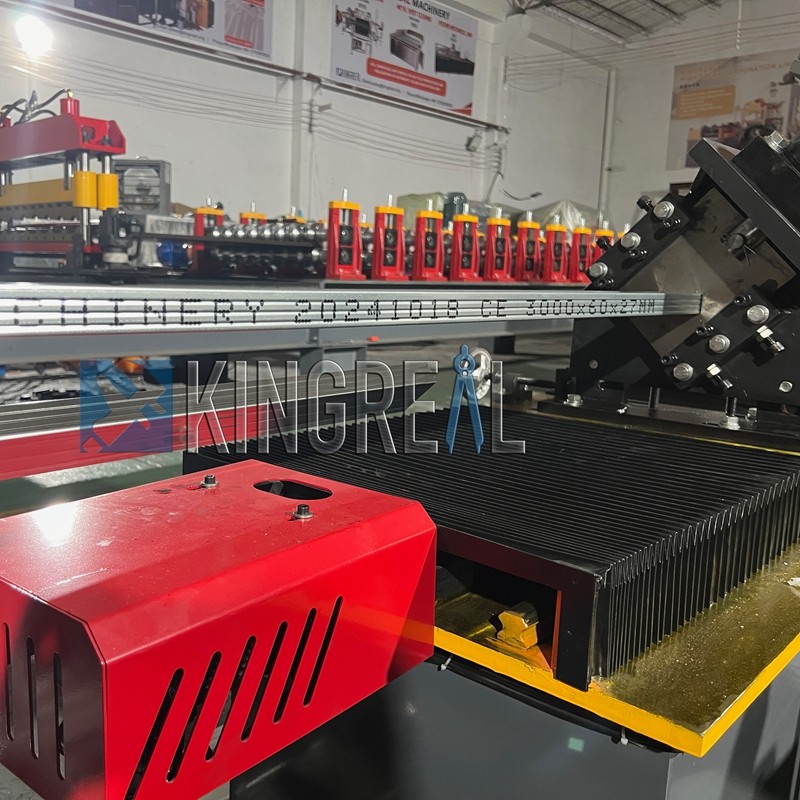

Solution 1: Engrave the logo pattern on the roller of the roll forming machine

1.1 Overview of the solution

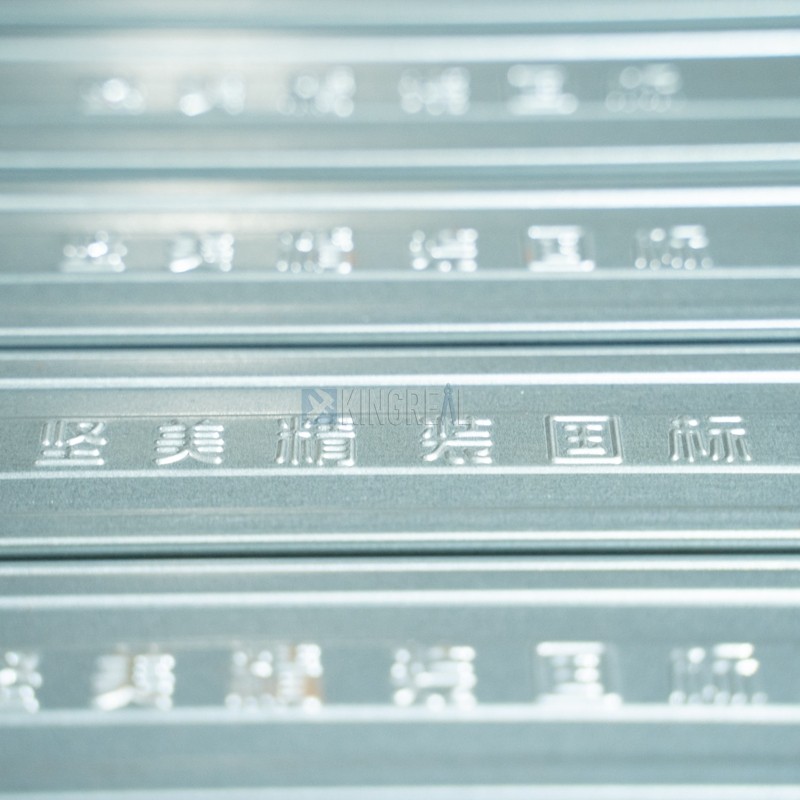

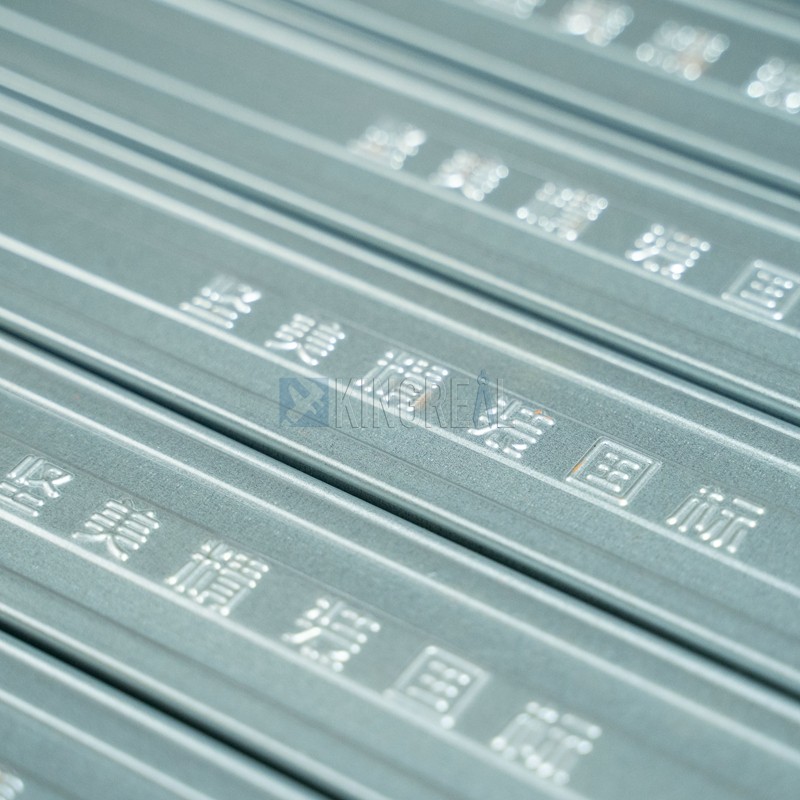

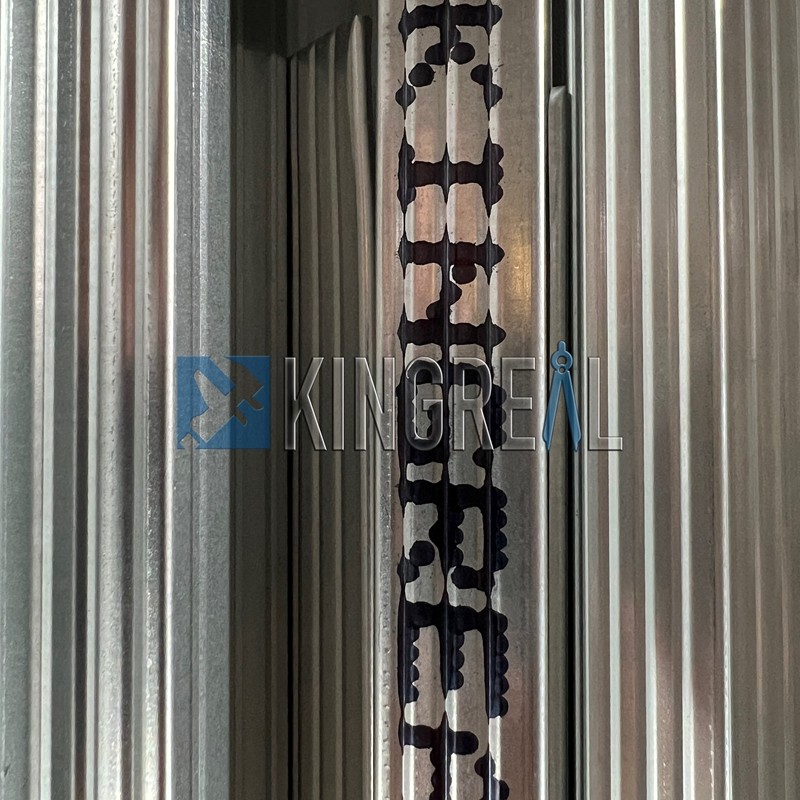

KINGREAL engineers boldly proposed to engrave the required logo pattern on the roller of thefurring channel machine. The core idea of this solution is to simultaneously engrave the customer's specified Logo during the false ceiling channel forming process by rolling while the metal coil is being fed into the roll forming machine. This solution realizes the simultaneous forming and engraving in the production process, greatly improving production efficiency, while also ensuring the accuracy and consistency of the Logo.

1.2 Implementation steps

When implementing this solution, the roller needs to be precisely processed first to ensure that the engraved Logo pattern is clear and durable. The specific steps are as follows:

1. Design Logo: According to the Logo design file provided by the customer, make necessary adjustments and optimizations to meet the technical requirements of engraving.

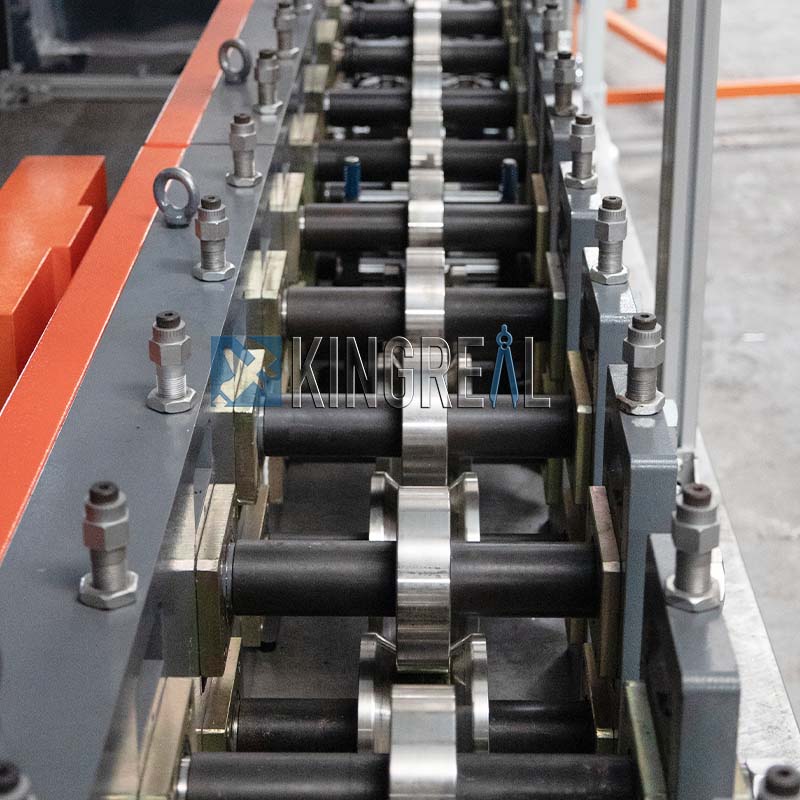

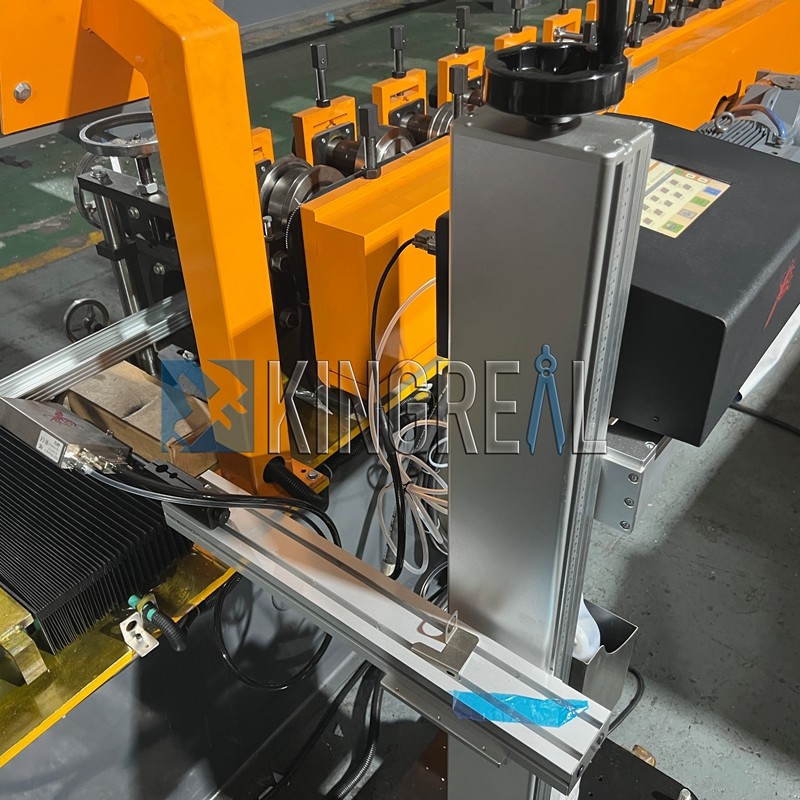

2. Engraving roller: Use high-precision laser engraving equipment to engrave the designed Logo on the roller surface. This process requires strict control of depth and clarity to ensure the quality of the finished product.

3. Debugging the roll forming machine: Install the roller with the Logo engraved on it to the furring channel machine and debug it to ensure that the Logo can be accurately engraved on each false ceiling channel during the production process.

4. Trial production: Conduct small-batch trial production to test the engraving effect and molding quality of the logo to ensure that it meets customer requirements.

1.3 Advantage Analysis

- Efficiency: This solution combines the logo engraving with the molding process, eliminating the separate printing step and saving production time.

- Integrated design: Through roller engraving, the logo and the false ceiling channel are integrally molded, avoiding the possible shedding and blurring in the later printing.

- Quality assurance: The logo engraved during the molding process has higher wear resistance and stability, and can adapt to different use environments.

1.4 Applicable scenarios

This solution is suitable for large-scale false ceiling channel manufacturers, especially those who want to add unique logos to their products to enhance their brand image. Due to its high production efficiency and good engraving effect, it is suitable for occasions that require mass production.

Solution 2: Equip the u channel machine with a coding system

2.1 Solution Overview

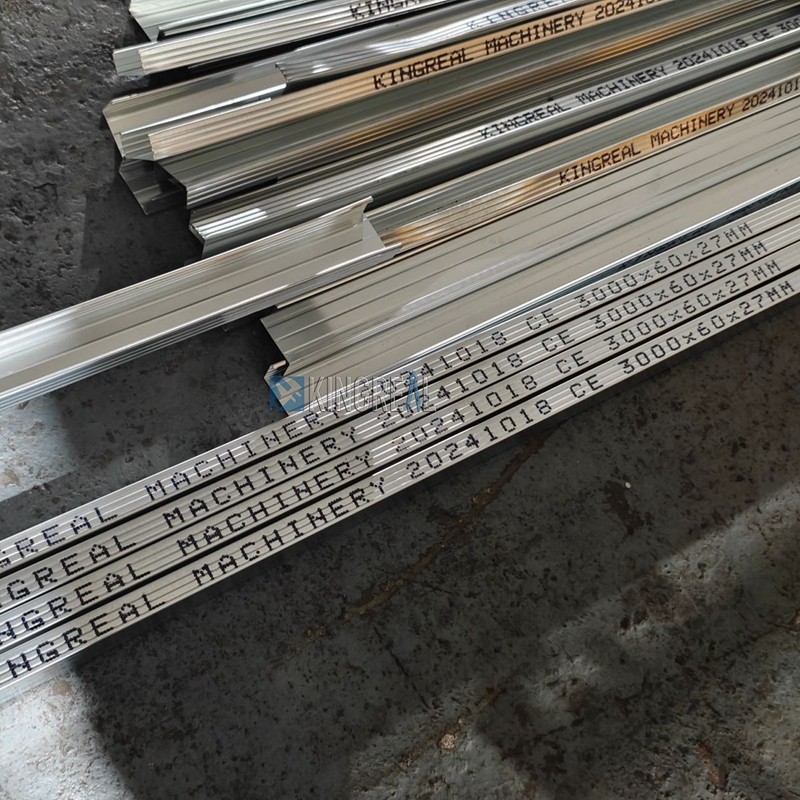

Another solution is to equip the u channel machine with a coding system. In this solution, the u channel can be quickly printed with the set Logo by passing through the inkjet device during the production process. The flexibility of the inkjet system makes it an ideal solution, and the Logo can be adjusted and modified at any time according to different needs.

2.2 Implementation steps

The steps to implement the inkjet system are as follows:

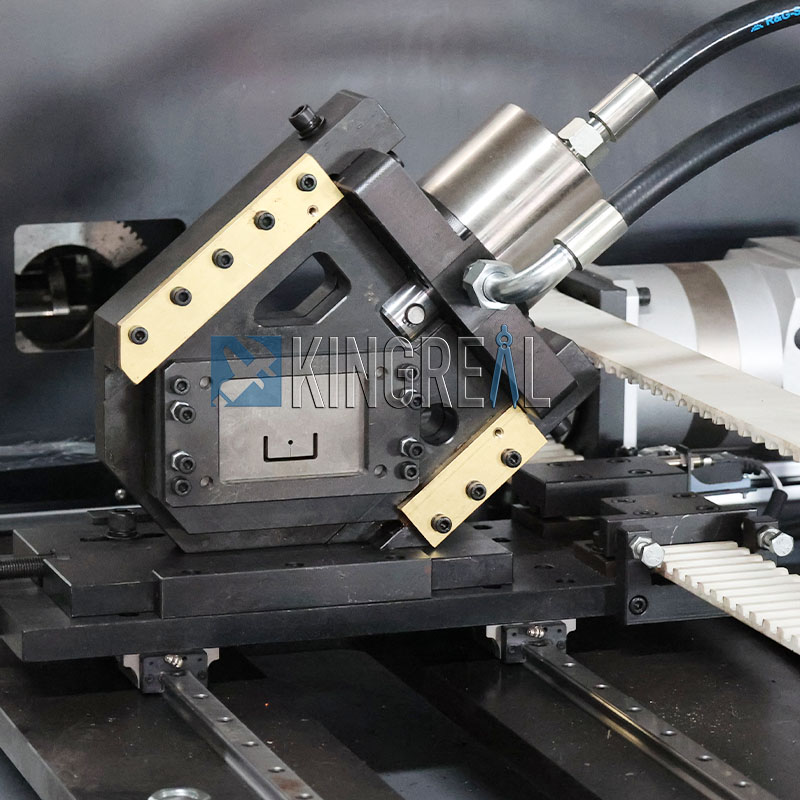

1. Selection of inkjet equipment: Select the appropriate high-speed inkjet equipment according to the actual needs and characteristics of the u channel machine.

2. Logo design and setting: Import the Logo file provided by the customer into the inkjet system and make necessary adjustments to ensure that the printing effect meets the requirements.

3. Equipment debugging: Debug the inkjet equipment to ensure the clarity, color and durability of the printing. This process requires multiple tests to ensure stable quality.

4. Production implementation: In formal production, the inkjet system is linked with the u channel machine to ensure that the Logo can be accurately printed on each u channel.

2.3 Advantage Analysis

- Flexibility: The inkjet coding system is highly flexible and can quickly adjust the logo according to customer needs, suitable for a variety of different designs.

- Strong adaptability: The inkjet coding can adapt to a variety of materials and surfaces, ensuring good printing effects in different environments.

- Low cost: Compared with roller engraving, the equipment investment and maintenance costs of the inkjet coding system are relatively low, suitable for small and medium-sized enterprises.

2.4 Applicable scenarios

This solution is suitable for false ceiling channel manufacturers with small or diversified production scales, especially those companies that have frequent changes in logo design. The flexibility of the inkjet coding system makes it an ideal choice for facing rapid market changes.

Benefits of false ceiling channels with logos

3.1 Core competitiveness

In today's highly competitive market, companies must have core competitiveness to stand out from many similar products. Printing the logo on the false ceiling channel can not only enhance brand awareness, but also enhance the added value of the product. Consumers usually have a higher degree of awareness and trust in the brand, and products with logos are often more likely to win the favor of customers.

3.2 Differentiated Marketing

By adding a logo to the false ceiling channel, the company can differentiate its products and distinguish them from other products on the market. Furring channels with unique logos can attract more potential customers and enhance the competitiveness of products in the market.

3.3 Enhance brand image

A clear and professional logo can not only enhance consumers' trust, but also convey the company's values and ideas. The logo printed on the furring channel can continuously strengthen the brand image and enhance customer loyalty during customer use.

3.4 Promote sales

Products with logos are often more attractive in the market and can effectively promote sales. When choosing false ceiling channels, consumers tend to choose products with brand logos because this usually means higher quality assurance and service commitment.

3.5 Value-added services

By engraving or printing the logo on the furring channel, the company can provide customers with personalized value-added services, such as customized products. This strategy can not only meet the personalized needs of customers, but also increase customer satisfaction and further consolidate customer relationships.

If you need a customized furring channel machine, welcome to consult us. We have professional staff to serve you and accompany you to visit the factory to let you have a deeper understanding of KINGREAL's u channel machine!