What Are The Advantages of Suspended Ceiling?

2024-09-13 15:44Suspended ceilings are like a secondary ceiling hung below the main ceiling. These are hung off of the existing ceiling in a metal grid which then has ceiling panels installed so that it looks like the actual ceiling. There are many different types of ceilings that are used in different buildings throughout the world nowadays, suspended ceilings are taking the building business by storm.As a professional sheet metal ceiling equipment manufacturer in China, KINGREAL is able to provide completed metal ceiling solutions, such as fully automated metal ceiling production lines, which can help customers produce suitable metal suspended ceilings efficiently.

How are ceiling panels made?

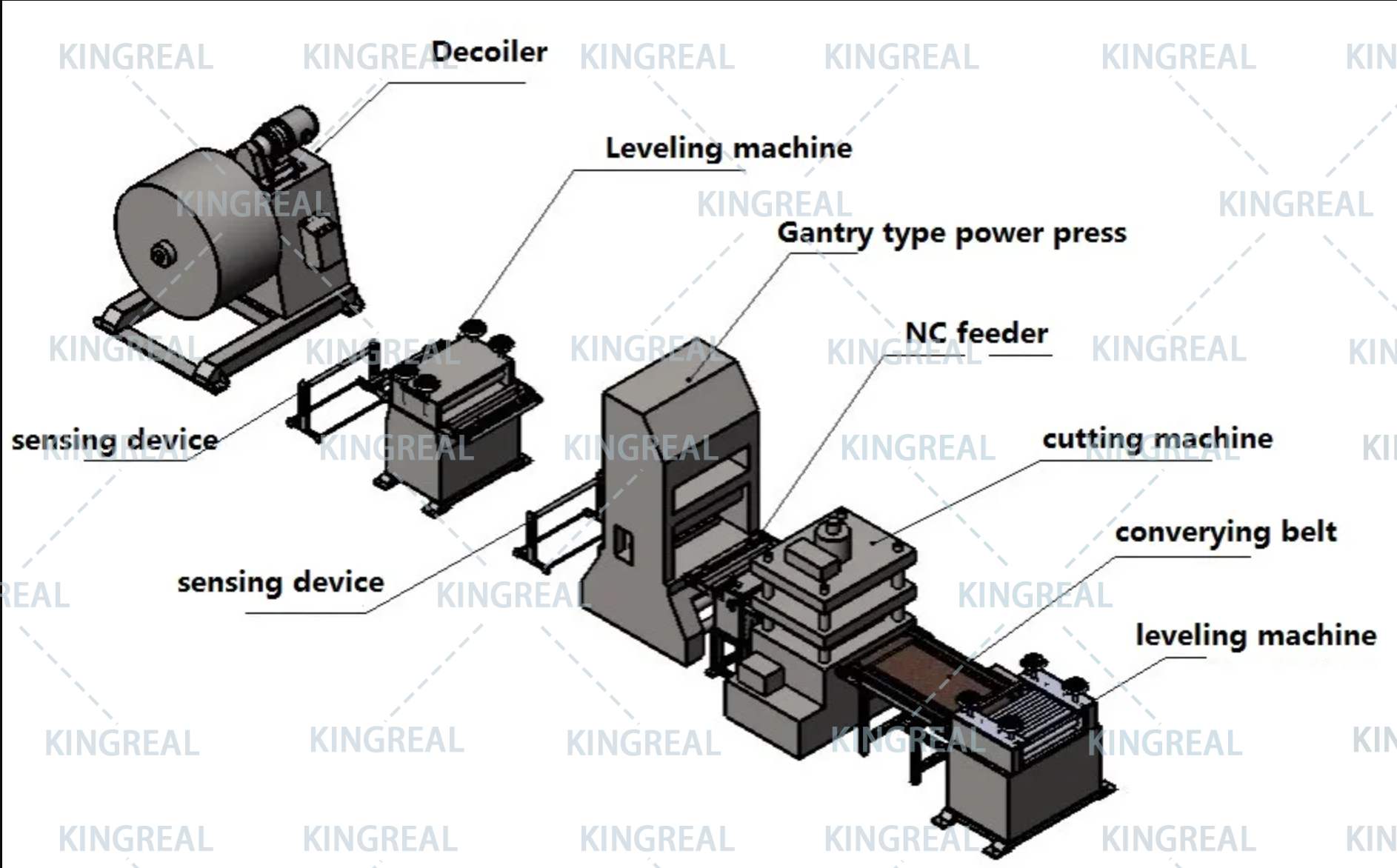

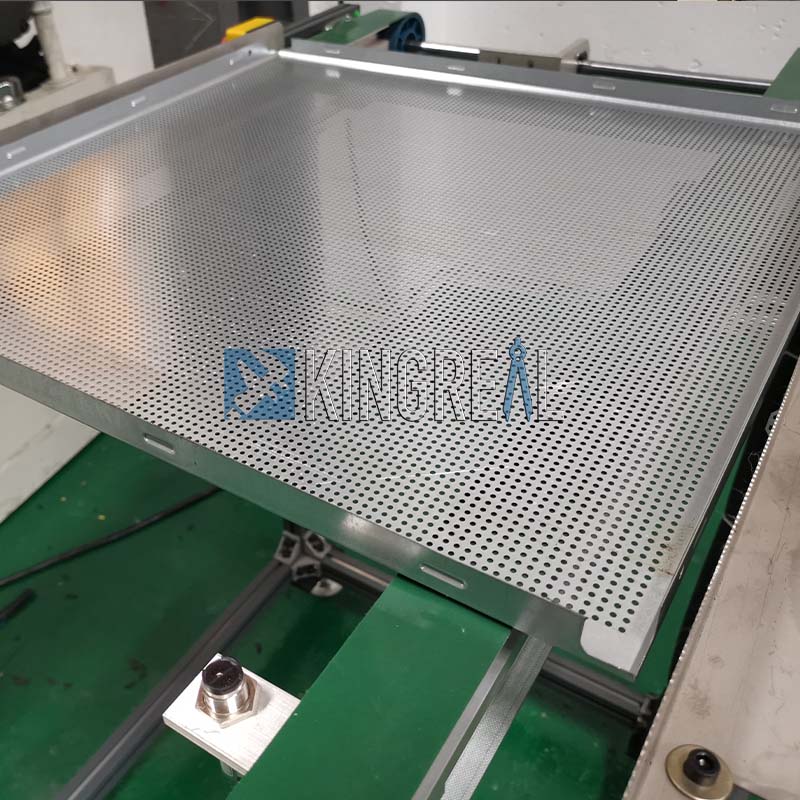

Metal ceiling tiles are produced by metal ceiling making machine. The manufacturing process of ceiling panels is a complex and sophisticated process involving a variety of high-tech equipment and strict quality control. The components of a modern fully automatic ceiling production line include Hydraulic Decoiler, Precision Straightener, Perforation Press, Servo Feeding Machine, Notching and Shearing Press, 2nd Precision Straightener, Tiles Flipping Machine, Automatic Tiles Feeding Machine, Auto Bending Forming Press, etc. These devices work together to ensure high quality and efficient production of ceiling panels.

First, the production process starts with a hydraulic decoiler, which unwinds the rolled metal material and prepares it for subsequent processing. Next, a precision leveler leveled the metal sheet to eliminate the warping and unevenness caused by the material during the rolling process and achieve the required flatness. Subsequently, the punching machine processes the necessary holes in the metal sheet to meet the design requirements. These holes are not only beautiful design elements, but also help with subsequent installation and ventilation.

After the material is initially processed, the servo feeder accurately feeds it into the notching and shearing machine for cutting and forming. The second precision leveling machine once again ensures the flatness of the material and is ready for the final forming process. The flipping machine will flip the ceiling during the production process to facilitate processing on different sides. The automatic feeder is responsible for feeding the processed metal sheet into the automatic bending and forming machine to complete the final forming process. The whole process is highly automated, ensuring production efficiency and product consistency.

Video About metal ceiling machine

The major advantages of suspended ceilings are

1.Compensate for the deficiencies of the original building structure

They are used to covering up air ducts and maintenance areas in the places like supermarkets and shopping centers. Besides, some homes of the original building roof beams, heating pipes, exposed outside is very unsightly, through the suspended metal ceiling to cover the above shortcomings, so that the top surface is neat and orderly and not cluttered.

2.Enhanced decorative effect

On a normal plastered ceiling it is very difficult to make alterations to piping or wiring without having to demolish it and start again. The suspended metal ceiling can hide many pipes and lines, but also can be reserved for the installation of lamps and lanterns. Besides, you need not to worry about dust containment as in plastered ceiling while demolishing it. Dust and debris containment is the main problem of homeowners whenever there is any remodeling or construction work.

3.Thermal insulation

Installing a suspended metal ceiling tile is like adding a layer of insulation, which acts as insulation and cooling, these panels may help lower home heating/cooling bills.

4.Noise reduction

Suspended ceilings offer superior acoustic properties far better than drywall ceilings to soften noises, so surrounding rooms are quieter. If you have a high demand for noise reduction in your room, you can also apply non-combustion-assisted acoustic cotton to the square panels, the Ceiling Tile Acoustic Textile Install Machine produced by KINGREAL can help you complete this step easily.

5.Convenient to clean

Kitchen and bathroom belong to the same is water vapor, fumes are mostly in the location, the metal ceiling tile can not only prevent water vapor into the roof can also prevent fumes scattered.

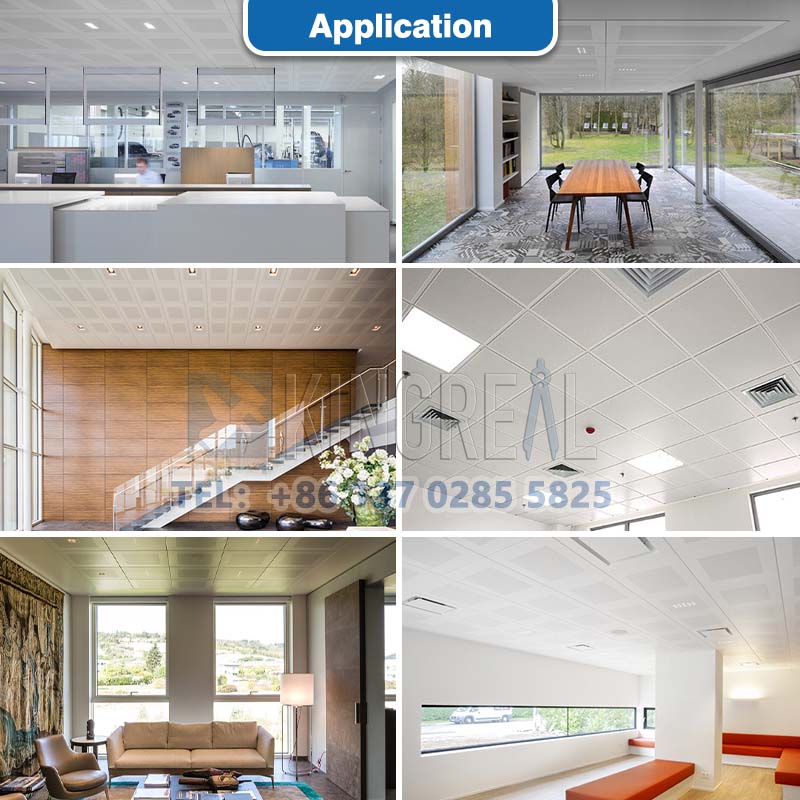

Application areas of metal ceilings

With the improvement of people's aesthetic level, the importance of ceilings in interior decoration has become increasingly prominent. In modern decoration, more and more people choose to install ceilings indoors instead of simple bare white walls. Ceilings can not only improve the aesthetics of the interior, but also effectively hide facilities such as wires and pipes, and enhance the overall sense of space. Therefore, ceilings are widely used in various indoor places, including classrooms, subway stations, supermarkets, homes, hospitals, hotels, etc.

In classrooms, ceilings can effectively absorb sound and improve students' learning environment; in subway stations, the combination of decorative and functional ceilings can enhance passengers' comfort; in supermarkets and shopping malls, the design of ceilings is often combined with the overall brand image to attract customers' attention. In the home, ceilings are not only practical facilities, but also an important element to create a comfortable living atmosphere. Hospitals and hotels pay more attention to the hygiene and easy clean of ceilings to ensure the safety and comfort of the environment.

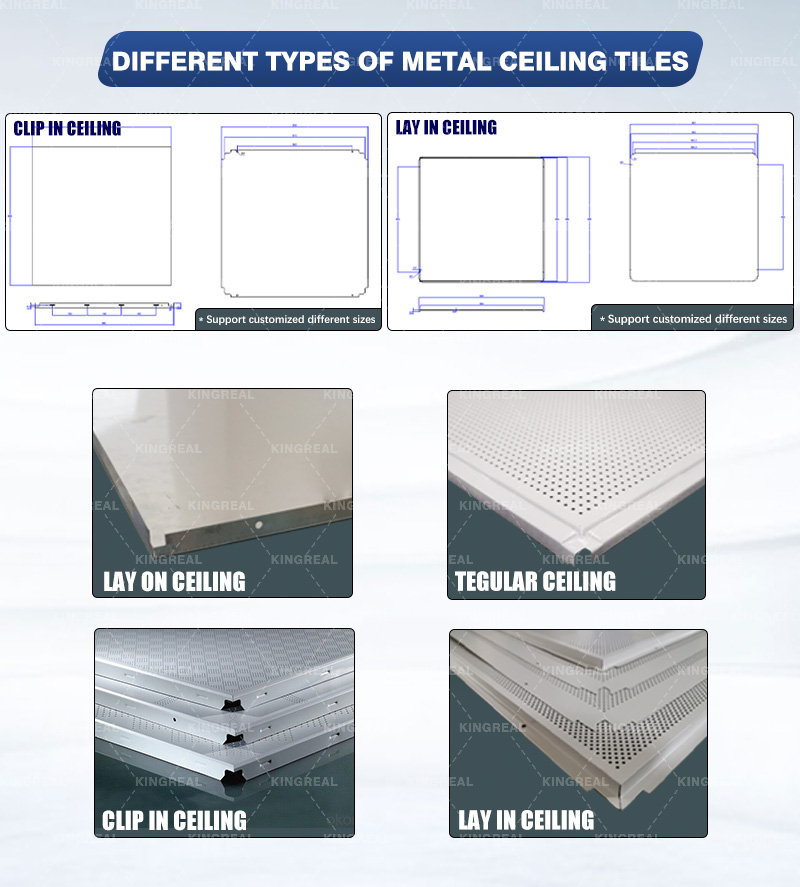

Types of metal ceilings

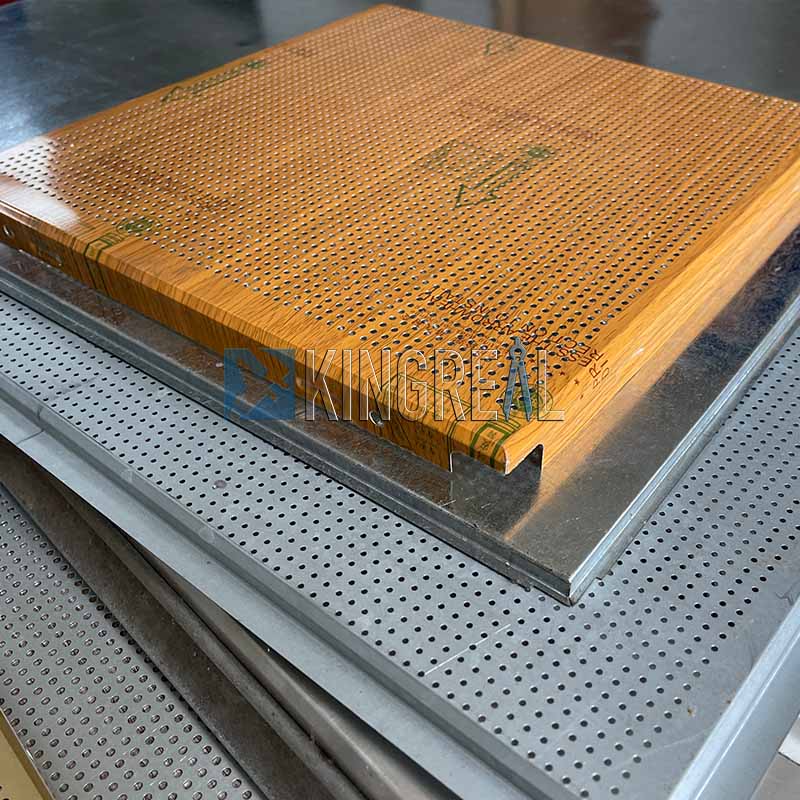

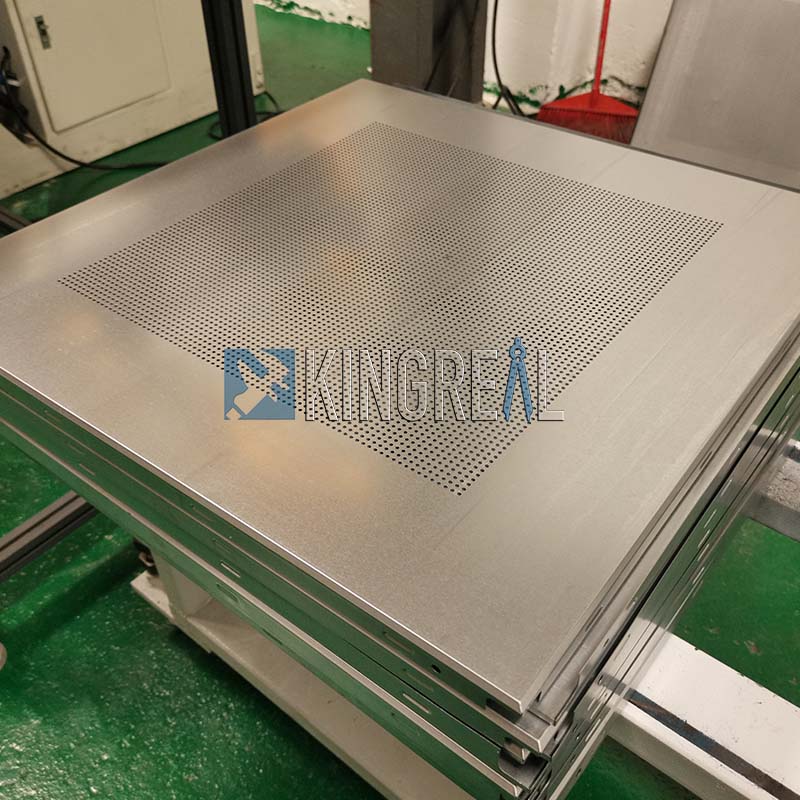

There are many types of ceilings, suitable for different application scenarios and design requirements. KINGREAL's metal ceiling making machinecan provide customized designs according to the specific needs of customers, ensuring that each ceiling meets customer expectations. Common ceiling sizes include 300x300mm, 600x600mm and 600x1200mm, and customers can choose according to the actual situation of the space.

In terms of type, ceilings usually have several main forms, including clip-in, lay-in and tegular. Clip-in ceilings are easy to install and replace, and are suitable for places that require frequent maintenance; embedded ceilings provide a smoother visual effect, suitable for environments that pursue beauty; tegular ceilings can create a more layered spatial experience, and are often used in high-end hotels and commercial spaces.

When choosing a ceiling, customers can choose a suitablemetal ceiling making machine for customized production according to their own needs and space characteristics. Whether it is style, size or function, KINGREAL can provide professional solutions to meet the needs of various customers.