What can coil perforation lines produce?

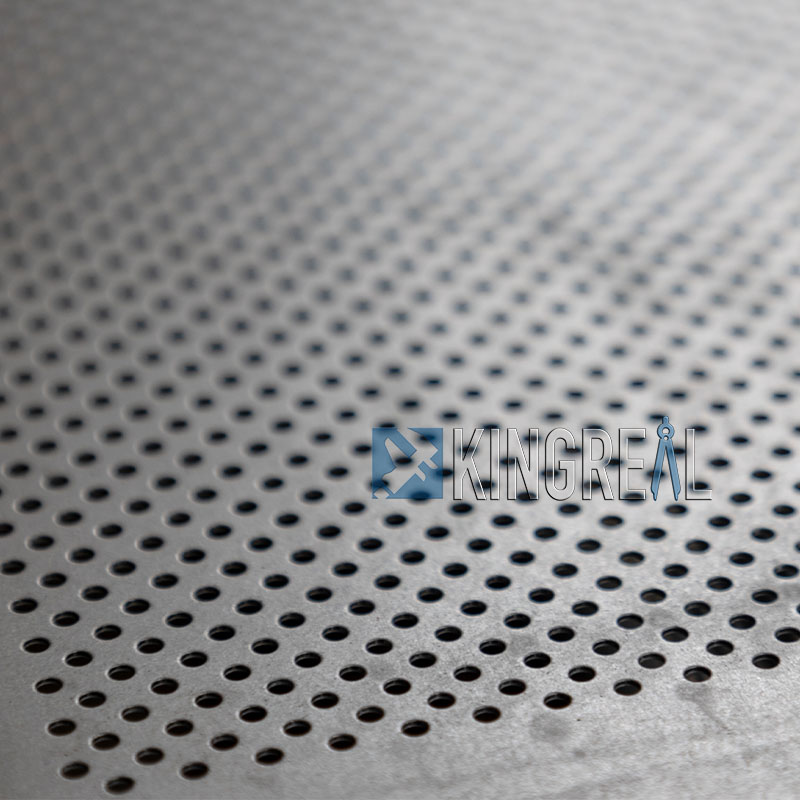

2025-02-22 12:00Coil perforation line is a device specially used to make metal sheets with holes through the punching process. These metal sheets with holes are widely used in subsequent processing, especially in the construction, decoration, electronics, automobile and other industries.

The metal perforated machine can manufacture various types of perforated metal sheets. Common punching types include round holes, square holes, long holes, etc. These hole types can be customized according to customer needs to meet the application requirements of different fields.

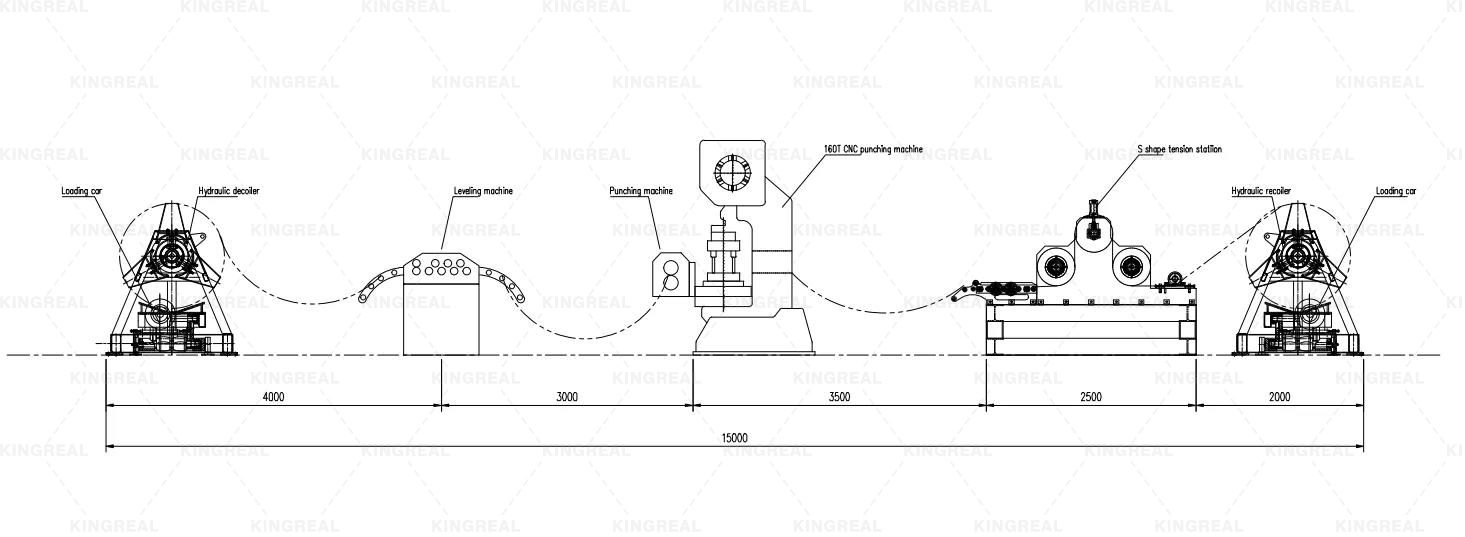

Workflow of metal perforated machine

● Unwinding: The first step of the perforated metal production line is to unwind the metal coil through the decoiler. This process ensures the flatness of the metal sheet and helps the accuracy of the subsequent punching. The decoiler can be adjusted according to the diameter and width of the coil to adapt to metal sheets of different specifications.

● Punching: The unfolded metal sheet is conveyed to the coil perforation line. The metal perforated machine is equipped with a punch of a specific shape and size, which impacts the metal material through up and down movement to form various types of hole types, including round holes, square holes, long holes, etc. This process requires not only high precision of the equipment, but also the durability of the punching tool to cope with high-intensity work requirements.

● Rewinding or cutting: After the punching is completed, the coil perforation line can choose two directions of processing. On the one hand, the recoiler is equipped to reel the metal sheet with punching holes for subsequent storage and transportation; on the other hand, the cutting station is equipped to cut the punched metal sheet into a specified length to meet different processing needs.

Three types of metal perforated machines

According to different uses, perforated metal production lines can be divided into three main types: metal ceiling perforation line, coil perforated rewinding production line, and coil perforated cutting production line. The emergence of different types of metal perforated machines enables enterprises to meet different market needs more flexibly and achieve diversified production.

Metal ceiling perforation line

Metal ceiling perforation line is a special equipment that combines the metal perforated machine with the metal ceiling machine. It produces metal ceilings with punching through a punching process. This type of ceiling is usually used in commercial buildings, exhibition halls, airports and other places, and has the characteristics of beauty, light transmission and ventilation.

●Advantages:The metal ceiling produced using the metal ceiling perforation line can not only improve production efficiency, but also reduce labor costs. Through automated operation, the consistency of the size and hole type of the ceiling is ensured, thereby improving the quality of the finished product.

Coil perforated rewinding production line

Coil perforated rewinding production line is a device that combines the perforated metal production line with a recoiler, which can wind up the metal material after punching for subsequent processing and transportation. It is commonly used in the production of perforated baffle ceilings.

●Advantages: The design of the coil perforated rewinding production line enables the product to be quickly wound up after punching, reducing material waste. The wound metal material is easy to store and transport, reducing logistics costs. At the same time, the automated operation of the recoiler improves production efficiency.

Coil perforated cutting production line

Coil perforated cutting production line is a kind of equipment that combines perforated metal production line with cutting station, which can shear the punched sheet into specified length after punching. Perforated metal production line with cutting station is often used to manufacture products such as wall panels.

●Advantages: The punching design of wall panels produced by coil perforated cutting production line can reduce the weight of wall panels and facilitate installation and transportation. At the same time, the precise control of the cutting station ensures the consistency of the size of each wall panel, which improves the construction efficiency.