What is metal wall panel machine?

2025-03-22 12:00Metal wall panel machine is a kind of equipment specially used for producing wall panels. By putting metal coils into the metal wall panel making machine, various types and sizes of wall panels can be produced through a series of work processes such as unwinding, leveling, forming, and shearing. These wall panels are widely used in the construction industry, especially in high-end places such as airports, railway stations, offices, etc.

Working principle of metal wall cladding panel machine

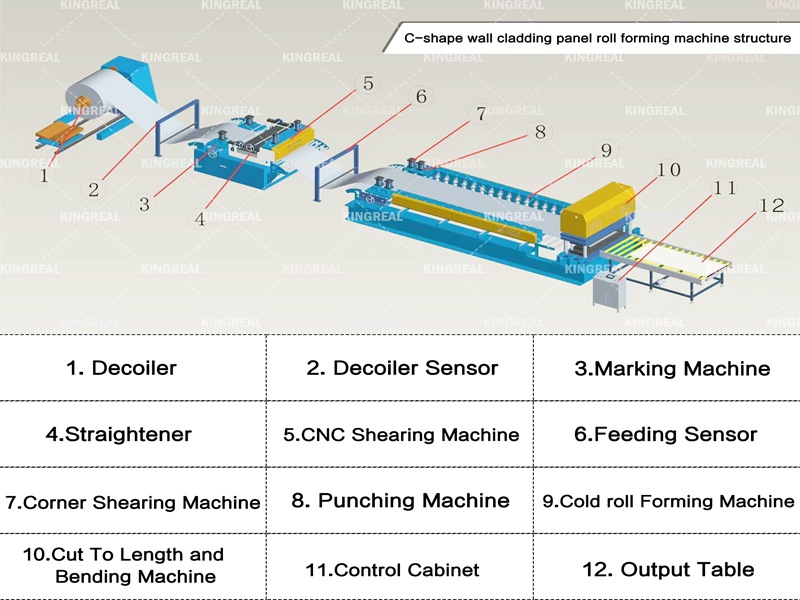

The working principle of metal wall cladding panel machine is mainly realized through the following steps:

Unwinding: First, the metal coil is placed on the decoiler. After the machine is started, the coil is flattened and sent to the subsequent process.

Leveling: Through the straightener, the metal coil is adjusted to the best state before entering the roll forming machine to ensure the smooth progress of the subsequent forming process.

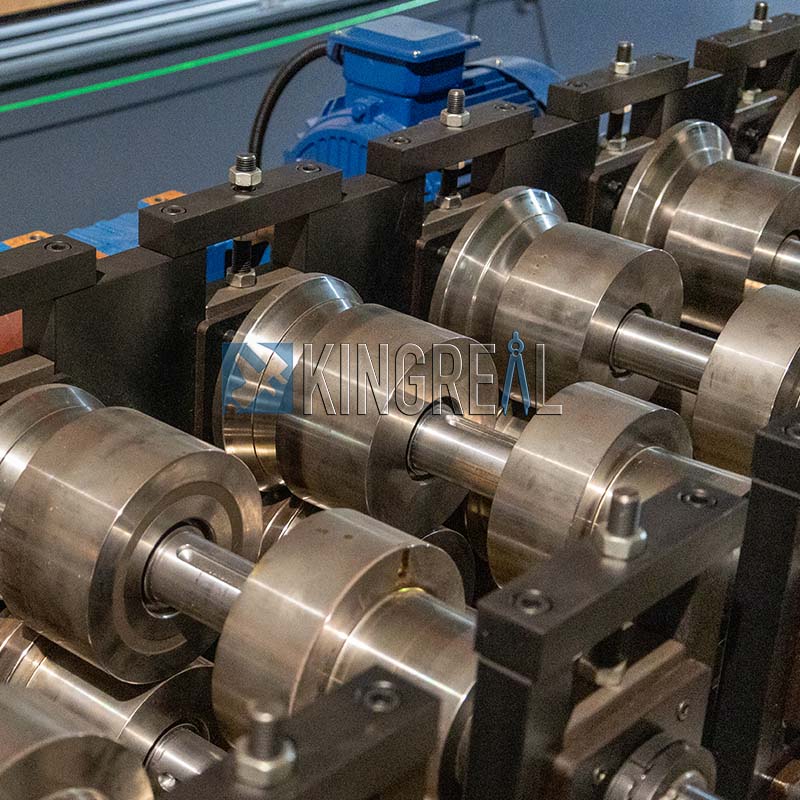

Forming: The metal coil passes through a series of rollers and is cold-bent into the required wall panel shape in the roll forming machine. The design and arrangement of the rollers are directly related to the accuracy and effect of the forming.

Shearing: After the formed wall panel reaches the set length, it is cut through the shearing station to finally produce a finished product that meets the specifications.

This efficient and automated production process enables the production of wall cladding panels to be carried out quickly and stably, meeting the market demand for wall panels.

Components of the metal wall panel making machine

The metal wall cladding panel machine is mainly composed of the following key components:

Decoiler

The main function of the decoiler is to unwind the metal coil and feed it into the subsequent process. It can ensure that the coil is not twisted or damaged during the uncoiling process, laying the foundation for subsequent leveling and forming.

Straightener

The straightener is used to level the metal coil to ensure the flatness of the material surface and provide a good foundation for forming. The accuracy of the leveler directly affects the effect of subsequent forming and can effectively reduce defects in production.

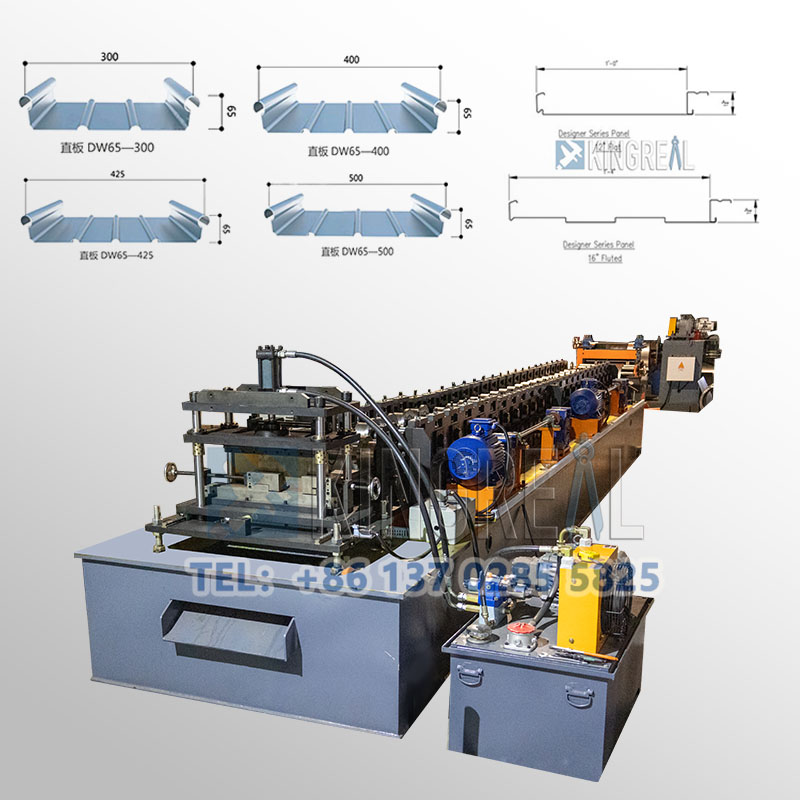

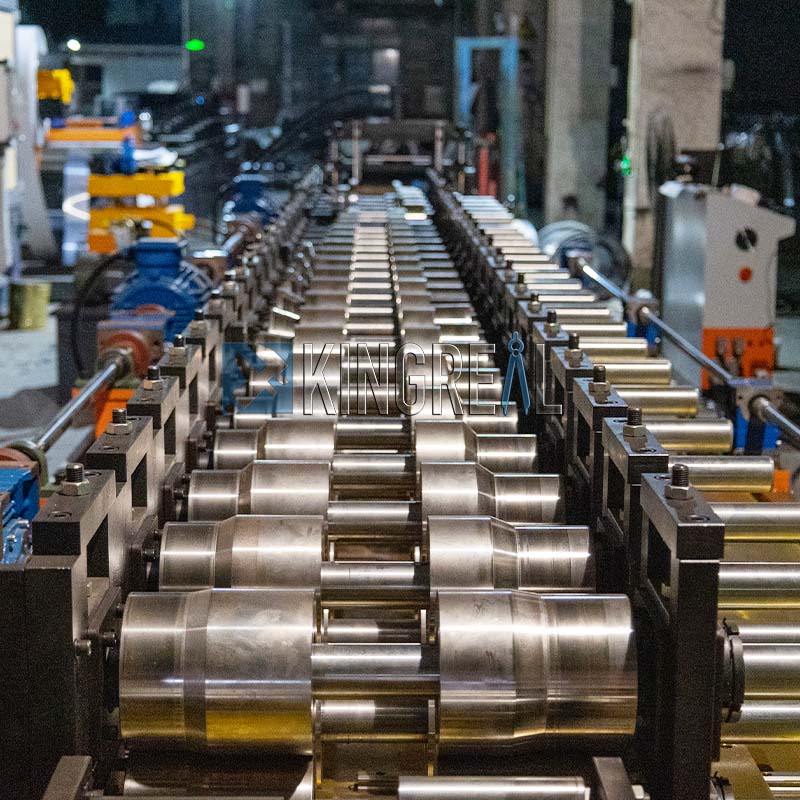

Roll forming machine

The roll forming machine is the core part of the metal wall cladding panel machine. It cold bends the metal coil into a specific wallboard shape through a series of rollers. The design of the forming machine and the selection of materials are crucial, affecting the speed and quality of forming.

Shearing station

The shearing station is responsible for cutting the formed wallboard according to the set length. High-quality blades can ensure the accuracy of shearing, produce finished products that meet standards, and avoid waste and the generation of unqualified products.

Application fields of metal wall panel making machine

The wall panels produced by metal wall cladding panel machines are widely used in many fields, mainly including:

1. Airports and railway stations

Due to the high requirements for the aesthetics and durability of building materials, the application of wall panels in airports and railway stations is becoming more and more common. Wall panels can not only enhance the appearance of the building, but also provide good sound insulation and fire resistance.

2. Offices

In modern office design, wall panels, as an important interior wall material, are widely used in partitions, wall decoration, etc. The diversity and easy installation of wall panels make them an ideal choice in modern office environments.

3. Commercial buildings

In commercial buildings such as shopping malls and hotels, wall panels are not only used as decorative materials, but also effectively enhance the functionality of the building, such as heat insulation and sound insulation. Its diverse design and color selection can meet the needs of different commercial spaces.

4. Industrial plants

In industrial plants, wall panels can not only provide good isolation effects, but also resist the impact of the external environment on internal equipment and personnel. The durability and strength of the wall panels make them ideal for industrial buildings.

Advantages of the metal wall panel machine

1. Can produce different types of wall panels

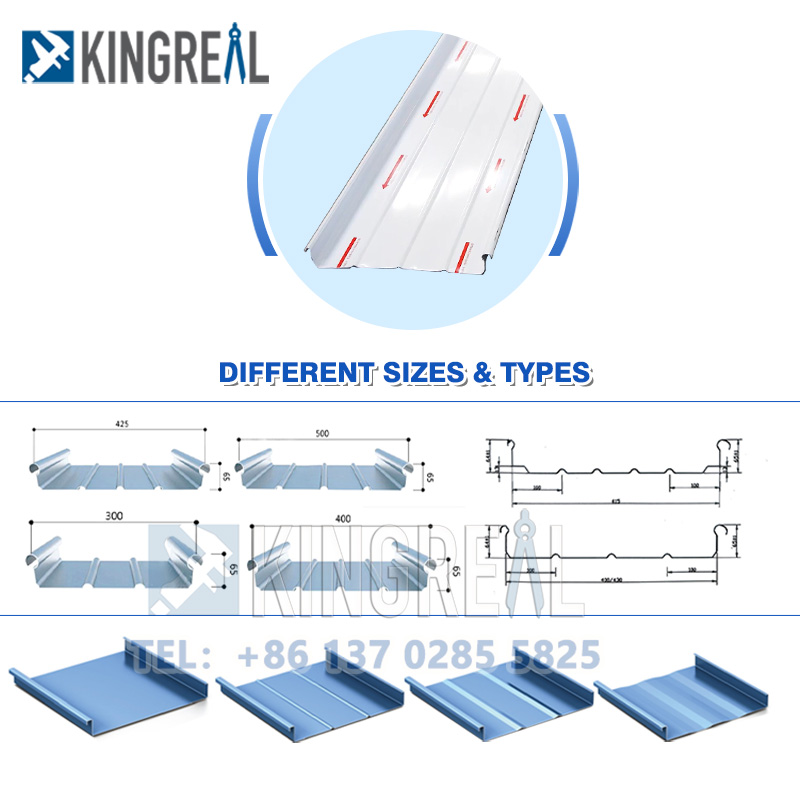

KINGREAL metal wall cladding panel machines are able to produce a variety of common types of wall panels, such as flat panels, small V ribs, clip relief, large V ribs, small pencil ribs and large pencil ribs.

2. Fast forming speed

KINGREAL metal wall panel making machines use high-quality, high-hardness raw materials to produce rollers to ensure fast forming speed and good forming quality. By adjusting the roller set, customers can flexibly produce wall panels of different sizes, which improves production flexibility and efficiency.

3. High-precision shearing

The shearing station uses high-hardness blades to cut out high-precision finished products. The high-quality shearing system ensures that the size and appearance of each finished product meet the standards, reducing rework and waste caused by improper cutting.

4. High leveling

The straightener has extremely high requirements for the leveling of metal coils, which can ensure the stability of the coils in subsequent forming steps. The improvement of this basic process provides a guarantee for the final forming effect and reduces defects in production.

5. High degree of automation

The modern metal wall cladding panel machine has a high degree of automation, which can reduce manpower input and improve production efficiency. Through the automatic control system, the operator can monitor the production status in real time and flexibly adjust the parameters to ensure the smooth and efficient production process.

Future development trend

With the continuous development of the construction industry, the future trend of metal wall panel making machines will develop in the direction of greater intelligence, environmental protection and efficiency.

1. Intelligent production

The future metal wall cladding panel machine will pay more attention to intelligent management, and achieve real-time monitoring and fault warning by introducing advanced sensors and data analysis technology. Intelligent production will improve production efficiency, reduce human errors and improve product quality.

2. The use of environmentally friendly materials

With the enhancement of environmental awareness, the design of metal wall panel making machines will pay more attention to the application of environmentally friendly materials. The use of recyclable and renewable materials can reduce the environmental impact during the production process and meet the requirements of sustainable development.

3. Customized production

The market demand for personalized and diversified wall panels is increasing. In the future, metal wall cladding panel machines will provide customized production services according to customer needs. This flexibility will enable wall panel manufacturers to better meet market changes and enhance their competitiveness.

4. Improve production efficiency

In order to adapt to the rapid changes in market demand, metal wall panel making machines will continue to upgrade their technology to improve production efficiency and stability. Future equipment will have higher cutting speeds and lower failure rates, thereby improving overall production capacity.