What is Stud and Track Making Machine?

2025-01-19 17:00Gypsum channel roll forming machine

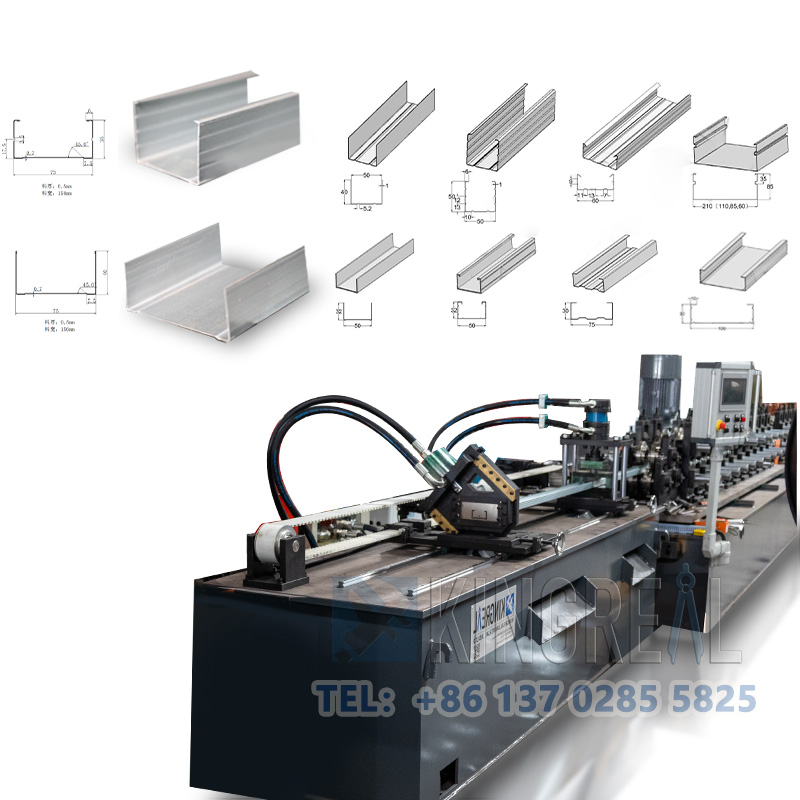

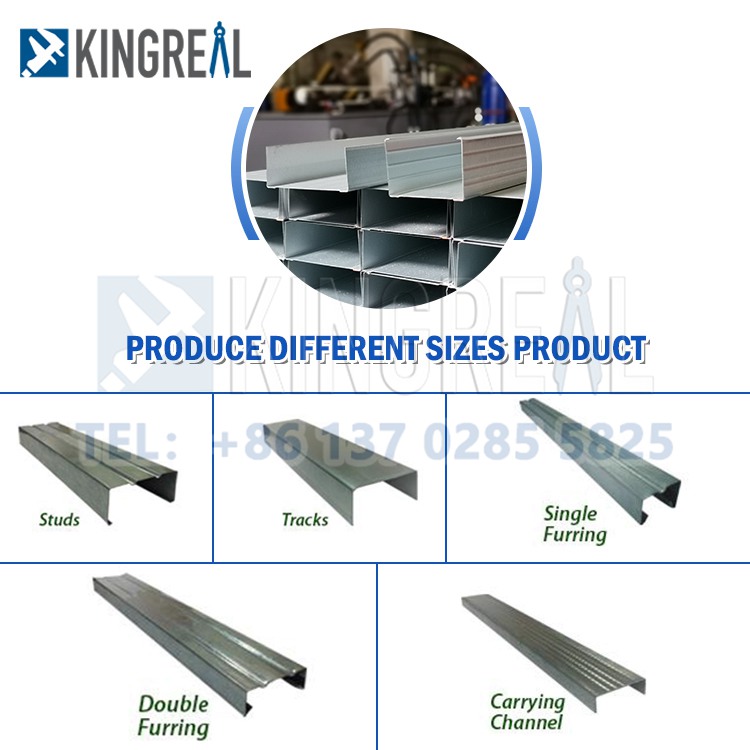

Stud and track making machines are specifically designed for the production of gypsum ceiling profiles (studs and tracks). These profiles are essential components in suspended ceiling systems and are commonly used in residential, commercial and industrial buildings due to their light weight, thin thickness and fast assembly speed.

The gypsum channel roll forming machine converts raw materials such as galvanized steel, aluminum or other metals into precise gypsum channels through a continuous roll forming process. KINGREAL stud and track making machines can produce studs and tracks of different sizes and types. In addition, these stud and track making machines have automation functions and high-speed production to ensure consistent quality and efficiency.

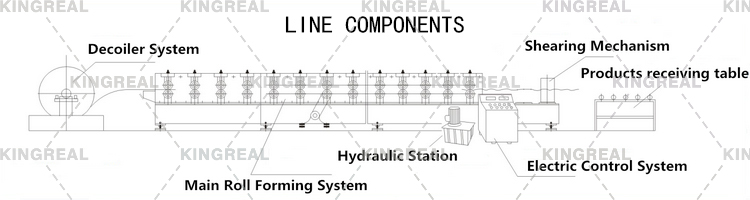

Main components of gypsum channel roll forming machine

- Decoiler

- Main Roll Forming Machine

- Hydraulic Fly Punching and Shearing

- Product Table

Workflow of stud and track making machine

Unwinding--Forming--Flying Punching and Shearing--Output

Parameters of gypsum channel roll forming machine

| Material | GI Strip |

| Material Thickness | 0.35mm-1.05mm |

| Production Speed | up to 100m/min |

| Shearing Accuracy | ±1.0mm/3m |

Features of KINGREAL stud and track making machine

With inkjet function

KINGREAL stud and track making machine is equipped with advanced inkjet function, which can customize and print its brand logo for customers while the stud and track is being formed. Through roller rolling technology, the logo pattern is accurately printed on the finished product, helping customers to complete brand building in advance during the production process and avoiding the additional process of inkjet in the later stage. This function not only improves production efficiency, but also effectively improves the market recognition of the brand.

Automatic packaging machine

In order to maximize production efficiency and achieve fully automated operation, KINGREAL gypsum channel roll forming machine is equipped with an automatic packaging machine. After the Stud and Track are formed, the finished product is automatically transported to the packaging area and can be automatically packaged without manual intervention. This design greatly reduces manpower input and reduces the risk of manual operation, while ensuring the standardization and consistency of packaging, thereby improving the work efficiency of the entire production line.

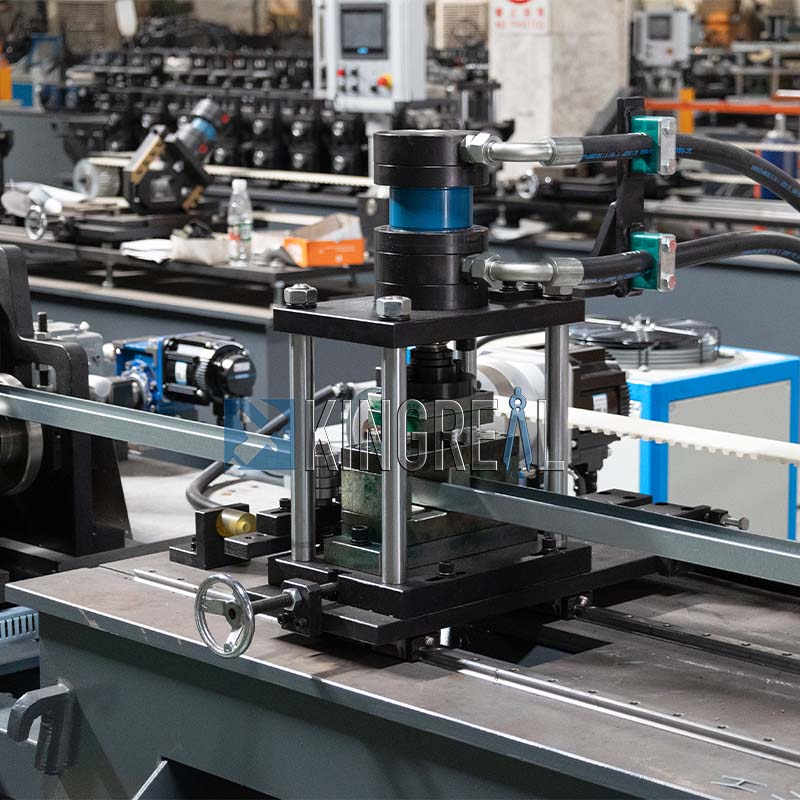

Flying punch and flying shear station

KINGREAL stud and track making machine is equipped with a flying punch and flying shear station, which can cut without stopping the machine during operation, greatly saving production time. When cutting the drywall profile, the flying punch and flying shear system ensures efficient cutting and continuous production of the product, avoiding the cumbersome steps of interrupting the production line, thereby improving the stability and efficiency of the production line.

High-speed production

KINGREAL stud and track making machine has an excellent production speed, which can reach up to 100 m/min. This efficient production capacity greatly improves the output of the overall production line, allowing enterprises to complete mass production in a shorter time and meet the market demand for efficiency.

Flexible solutions

KINGREAL provides a variety of flexible solutions to meet the needs of different customers. KINGREAL provides a variety of combinations of gypsum channel roller forming machines according to customer requirements, which can adjust different parameters such as production speed, production capacity, working thickness, etc. In addition, for the needs of stud and track making machines, KINGREAL also provides customized alternative solutions to ensure that the production parameters of different drywall channels can be adapted, such as different thickness ranges, stacking lengths, etc., to provide customers with the most suitable equipment configuration.

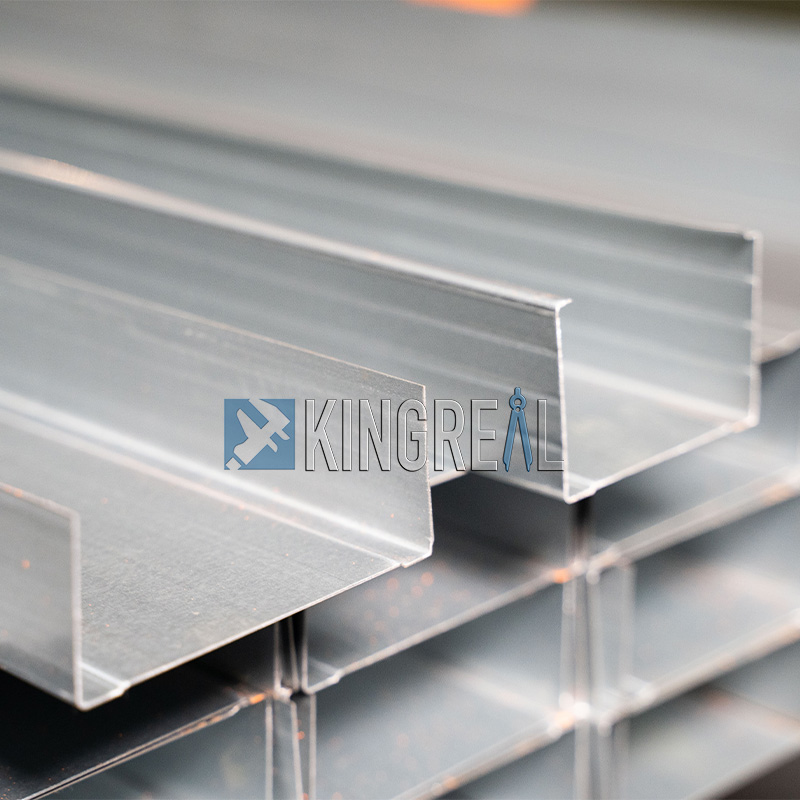

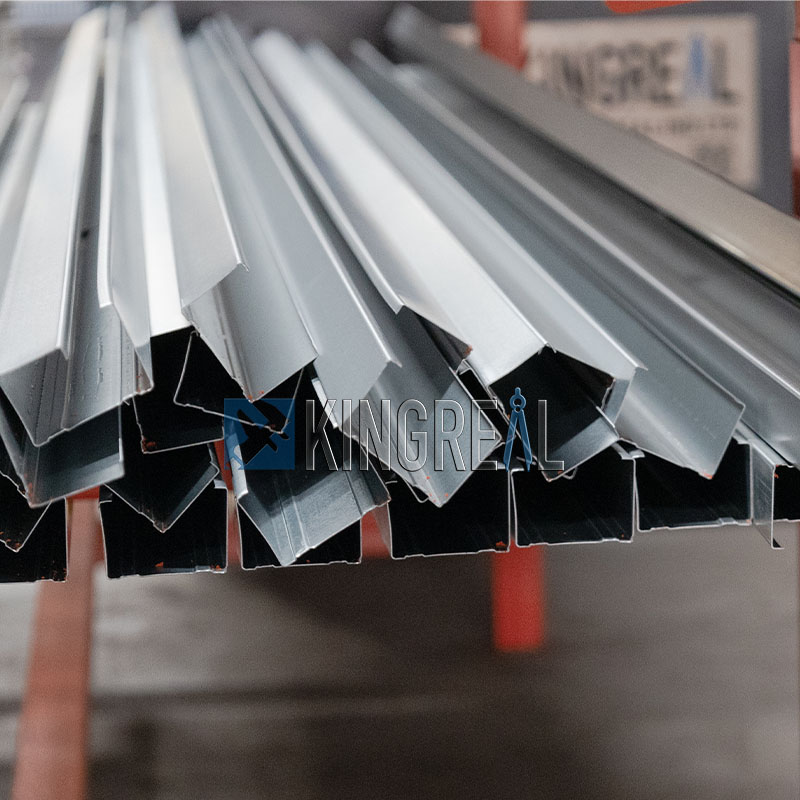

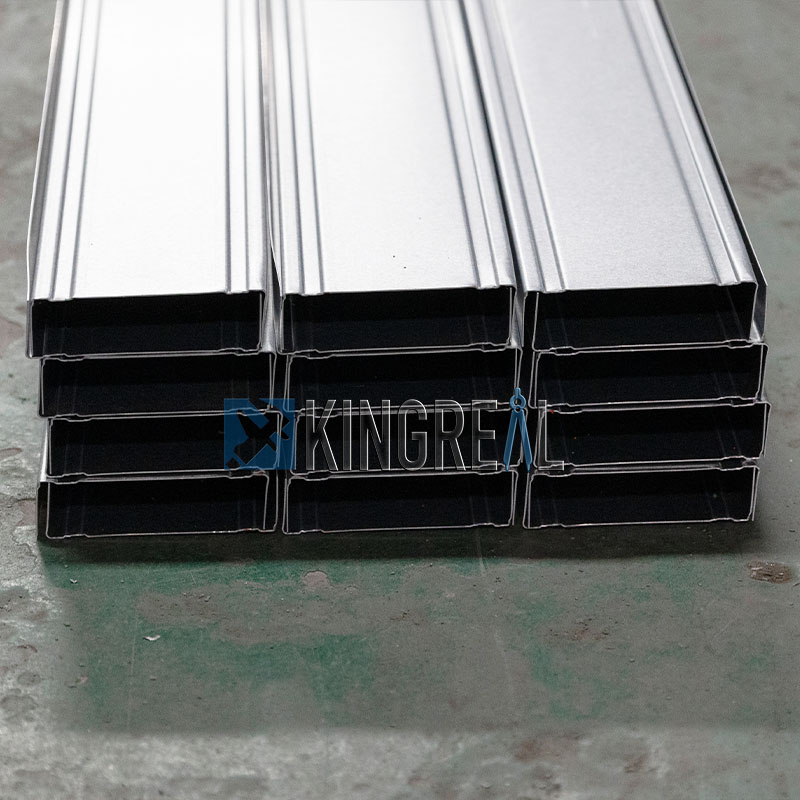

Product display

Successful project of KINGREAL stud and track making machine

KINGREAL's gypsum channel roll forming machine has been successfully exported to many countries, and has established close cooperation with customers in many international markets such as India, Russia, Canada, Saudi Arabia, Turkey, Chile, and the United Arab Emirates. With rich global experience, KINGREAL's engineers have a deep understanding of the specific needs of various countries' markets and can accurately grasp the subtle differences in machine parameters in different regions to ensure customized solutions.

Regardless of your market or industry needs, KINGREAL can provide you with professional consultation and support. If you need a gypsum channel roll forming machine, please feel free to contact KINGREAL, we will provide you with the most suitable equipment and services!